Dissembling and assembling solar tubes requires careful planning and execution to ensure both safety and effective reassembly. 1. Proper tools and safety equipment are essential, as this process often involves working at heights or with delicate materials. 2. Understanding the structure of solar tubes will aid in disassembly, which typically involves removing the outer casing and carefully detaching internal components. 3. Following step-by-step procedures for both disassembly and assembly will ensure everything goes back together smoothly, thus maximizing efficiency. 4. Regular maintenance post-assembly is critical to ensure the longevity of the system and to prevent any potential issues. Each of these points plays a crucial role in the successful management of solar tube systems.

1. UNDERSTANDING SOLAR TUBES

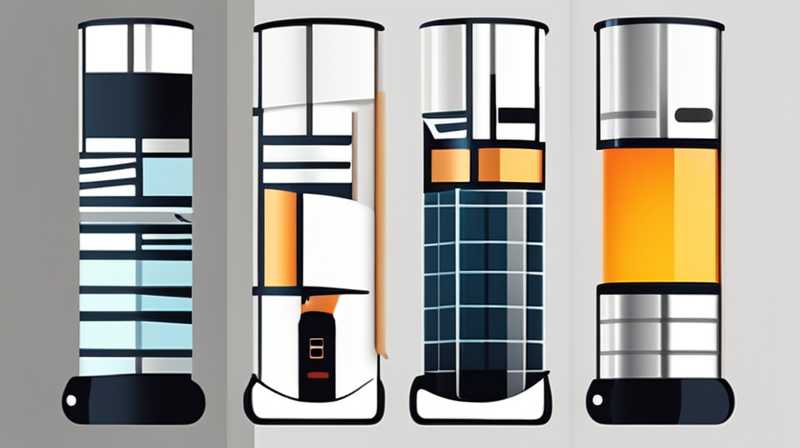

Solar tubes, also referred to as solar tubes collectors or evacuated tube collectors, are an increasingly popular option in solar energy systems. The mechanism behind these devices relies on a series of glass tubes designed to absorb sunlight and convert it into thermal energy, which can then be utilized for heating purposes. The collector consists of an outer, clear glass tube, a vacuum space that minimizes heat loss, and an inner dark tube that absorbs solar energy. This structure captures and retains heat efficiently, therefore providing optimal performance in a range of weather conditions.

The design of solar tubes is instrumental in their performance. Due to the vacuum between the two layers of glass, heat transfer is significantly reduced, which enhances thermal retention compared to conventional flat panels. Furthermore, the unique shape allows sunlight to enter and be captured, with the ability to perform efficiently even on overcast days. It is vital for users to comprehend both the operational principles and physical construction of these devices to effectively undertake any maintenance or repair tasks.

2. GATHERING NECESSARY EQUIPMENT

Before embarking on disassembly or reassembly, it’s crucial to gather the appropriate tools and safety equipment. Essential tools include a screwdriver set, adjustable wrenches, and possibly a torque wrench for specific components. These tools will allow for effective loosening and tightening of the various fittings. Safety gear is equally important; individuals should don work gloves to protect against cuts and abrasions, sturdy footwear to avoid slips, and goggles to shield their eyes from debris.

In addition to tools, it is wise to have a clean workspace. Having a dedicated area ensures that all components are securely placed and organized, which minimizes the risk of losing small parts during the process. A checklist can also prove invaluable in ensuring that every component is accounted for upon reassembly. Effective preparation sets the stage for a smooth transition through the disassembly and assembly phases, reducing potential issues and waste of time in the long run.

3. DISASSEMBLY PROCEDURE FOR SOLAR TUBES

The disassembly phase begins with a thorough inspection of the unit. It is vital to identify all fittings and connections that must be removed prior to handling the solar tubes. Begin by cutting off power supply to the system to eliminate any risk of accidents. Each solar tube is generally secured with brackets or clips that must be carefully released without applying too much force, which may cause accidental damage to any component.

Upon removing the mounts, detach the individual tubes one by one. It is advisable to take photographs during this process or create diagrams to ease future reassembly. Carefully grasp the outer tube and gently pull, ensuring that the internal components remain intact. If any components are stuck, apply precise force and check for any connection that may still be secured. Maintaining an organized approach aids in remembering where each component belongs, which is vital for effective reassembly.

4. ASSEMBLING THE SOLAR TUBES

Once disassembly is complete, focus shifts to putting the system back together. Start with the preparation of each individual component, ensuring all surfaces are clean and free from debris. When reattaching tubes, follow the diagrams or photos taken during disassembly to ensure conformity with initial configurations. Employing the correct fittings and resealing components, as necessary, will enhance performance and prevent leaks.

As you begin the assembly process, take your time with each step. Ensure that all components fit well without forcing anything into place. Once all tubes are secured and connected to the respective fittings, double-check the integrity of connections before powering the system back on. Upon successful assembly, conduct a brief test run to ensure that everything is operating as expected, further confirming that the assembly was done correctly.

5. MAINTENANCE AND PERFORMANCE CHECKS

Post-assembly, routine maintenance is vital for optimal solar tube performance. Regular inspections can help identify any potential issues before they escalate, ensuring that both efficiency and longevity are guaranteed. Cleaning panels and outlets regularly maintains a maximum solar intake, which is crucial for generating optimal heat. Any dust or grime accumulated over time can significantly decrease the effectiveness of solar tube technology.

In addition to external cleaning, check fittings and joints for any signs of wear or deterioration. Utilizing an infrared thermometer can be beneficial in detecting inconsistent heating patterns that may suggest leaks or damaged tubes. Addressing concerns promptly can save considerable costs and downtime in the future, demonstrating the importance of routine check-ups on solar systems.

FAQs

WHAT TOOLS ARE REQUIRED FOR DISASSEMBLING SOLAR TUBES?

Disassembling solar tubes necessitates a range of tools to facilitate an efficient and safe process. Essential tools include screwdrivers, adjustable wrenches, pliers, and possibly a torque wrench. Ensuring that you have both the right size and type of screwdrivers—such as flathead and Phillips—is also vital for loosening various fittings. In addition to these basic tools, safety gear like gloves, eyewear, and sturdy footwear is also essential to reduce the risk of injuries. A portable workbench or mat can also improve the ease of disassembly by providing a clean and organized work environment.

It is prudent to periodically inspect your tools before beginning to ensure they are in good condition. Having the right equipment on hand not only streamlines the disassembly process but also enhances safety. If you find yourself lacking essential tools, it is recommended to acquire them prior to starting the project, as this will prevent disruptions and frustration.

HOW OFTEN SHOULD SOLAR TUBES BE MAINTAINED OR CHECKED?

The frequency of maintenance checks for solar tubes largely depends on various factors, including geographical location and environmental conditions. As a general rule, it is advisable to conduct an inspection at least twice a year, with one check being conducted prior to peak sunlight seasons. Areas with heavy dust, debris, or pollution may require more frequent cleanings and checks to maintain optimal performance.

During these inspections, it is essential to clean the panels thoroughly to ensure maximum sunlight absorption. Using a soft brush or cloth will help in removing any debris without scratching the glass surface. Regular checks also allow for the identification and repair of any leaks or damages, which can prevent costly replacements down the line. Adopting a rigorous maintenance schedule contributes significantly to the efficiency and lifespan of solar tube systems.

WHAT ARE COMMON PROBLEMS WHEN ASSEMBLING OR DISASSEMBLING SOLAR TUBES?

When undertaking the assembly or disassembly of solar tubes, several common issues may arise. One frequent problem is misalignment of the tubes during reassembly, which can lead to inefficiencies in solar energy capture and potential leakage. It is crucial to refer back to documentation or photographs taken during disassembly to ensure that tubes are positioned correctly.

Another issue might involve damage to delicate components due to excessive force when disconnecting or reconnecting. To mitigate this risk, careful attention and gradual pressure are necessary, employing the correct tools for each type of connection. Lastly, forgetting to replace seals or gaskets can lead to significant problems post-assembly, so always verify that such components are in good condition and properly installed before completing the assembly process.

In summation, mastering the disassembly and assembly of solar tubes encapsulates a multifaceted approach involving careful planning, proper tools, thorough knowledge of the system’s workings, and adherence to maintenance protocols. Engaging in meticulous preparation, including gathering the appropriate equipment and understanding the assembly fundamentals, can significantly enhance the entire experience. With a focus on regular upkeep and a proactive stance toward addressing any potential complications, the longevity and efficiency of a solar tube system can be substantially increased. Furthermore, maintaining a diligent schedule of assessments and using the right techniques will further secure the investment in solar technology, thereby contributing to a more sustainable energy solution. By navigating the intricacies of installation and maintenance with precision, users not only optimize their system’s performance but also harness the full potential of solar power, making a meaningful contribution toward a cleaner and more efficient energy future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-and-assemble-solar-tubes-2/