Understanding the correct procedures for both dismantling and reassembling a mini solar light is essential for maintenance, repair, or upgrading purposes. 1. Disassembly allows access to internal components for troubleshooting, 2. Proper reassembly ensures functionality and longevity of the device, 3. Difficulty may vary based on the type and model of the light, 4. Safety precautions must be considered throughout the process. When embarking on this task, it is vital to follow systematic steps to avoid damage and ensure the light operates effectively after reassembly.

1. TOOLS REQUIRED

Before initiating the process of disassembly and reassembly, having the appropriate tools on hand is imperative for a smooth experience. Essential tools may include screwdrivers, pliers, and a soft cloth for handling delicate components.

Using the wrong tools can result in stripped screws or damaged parts, leading to frustration and potential harm to the solar light. Consider opting for a magnetic screwdriver to prevent losing small screws and enabling easier handling of components.

Additionally, a clean and clutter-free workspace helps in organizing the various pieces and components of the solar light, making it easier to keep track of everything during reassembly. Clearly labeling components or taking pictures can also assist in remembering where each part belongs, thereby simplifying the reassembly phase. With everything set up, you can confidently proceed to the next steps.

2. DISASSEMBLY PROCESS

Dismantling a mini solar light involves several steps that should be executed with precision to avoid damaging the unit. Initially, locate the screws that secure the casing, which are generally found on the base or sides of the unit.

Once identified, use the appropriate screwdriver to carefully remove these screws. It is advisable to keep them in a small container or a designated area to prevent misplacement. After unscrewing, gently lift the casing to reveal the internal components of the light. During this phase, pay attention to any wiring connections that may be present.

These connections can often hinder complete removal of the casing. Use a pair of pliers if necessary to detach any connectors without applying excessive force. It is crucial to document where each wire connects for an accurate reconnection later on. Following this process allows for inspection or repair of components like the LED bulb or the battery unit.

3. INSPECTING INTERNAL COMPONENTS

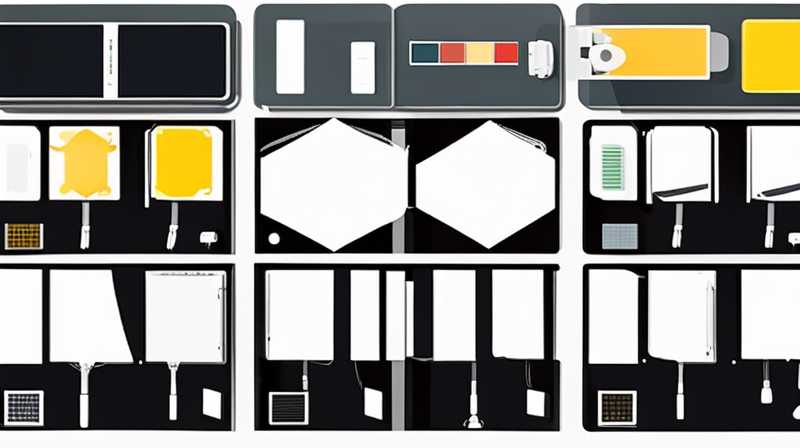

Once the casing has been removed, accessing the inner workings of mini solar lights opens a new area for observation and potential repair. Here, various components like the solar panel, rechargeable battery, LED bulb, and circuit board can be seen.

Taking the time to check each of these parts will determine if any replacements or repairs are necessary. The solar panel should be inspected for dirt or damage, as an impeded surface can lessen light absorption, affecting overall performance. If dirt is observed, cleaning it gently with a soft cloth is recommended.

Additionally, the battery should be checked for any signs of leakage or corrosion, as these indicators can signal the need for replacement. Replacing batteries should be done meticulously to ensure new ones match specifications. Moving on to the LED bulb, any discoloration or blackening of the bulb may suggest it is time for a new one. Thoroughly inspecting each component helps lead to an effective reassembly process.

4. CLEANING AND REPAIRING COMPONENTS

In the realm of DIY disassembly, taking the opportunity to clean and repair components of a mini solar light is advantageous. Use isopropyl alcohol and a soft cloth to gently clean circuit boards, ensuring no residual debris affects connectivity.

Pay mind to scraping over sensitive areas; patience will prevent potential damages. Additionally, examination of solder points on the circuit board can yield insight into needed repairs. If a solder joint appears cracked or compromised, reworking the solder with a soldering iron may be necessary.

This repair not only restores functionality but also extends the lifespan of the solar light. Engaging in maintenance activities with careful considerations fosters reliability and greater efficiency when using the light, reflecting a commitment to long-term durability.

5. REASSEMBLY PROCESS

Once all checks, cleans, and repairs have been conducted, the phase of putting everything back together can commence. Start by returning any internal components to their original positions systematically.

Following the previous documentation, attach wires to their corresponding connectors carefully to maintain the integrity of the connections. Ensure no loose wires are present that could interfere with the functionality.

After securing internal components, close the casing gently, aligning it correctly to ensure a snug fit. Afterward, reinsert all screws, tightening them adequately but avoiding over-tightening that could damage the casing. Following this structured method maintains the light’s efficiency while ensuring a hassle-free reassembly process.

6. TESTING THE SOLAR LIGHT

The act of functioning the solar light after reassembly marks a pivotal moment in ensuring all components work seamlessly together. Place the solar light in a location conducive to sunlight exposure. This step is significant for testing the solar charging capabilities of the solar panel.

The time taken for a full charge will vary based on environmental conditions; however, it is generally reasonable to expect results within a few hours. Observe whether the LED light illuminates at dusk, indicating that the charging mechanism operates correctly.

Any signs of malfunction during this test would necessitate revisiting the disassembly process. Ultimately, successful testing confirms the efficacy of both the disassembly and reassembly tasks, ensuring the solar light will perform its role effectively.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF SOLAR LIGHTS CAN BE DISASSEMBLED?

Many mini solar lights can undergo disassembly; however, the level of ease and type of construction will vary. Generally, solar path lights, garden lights, and decorative solar fixtures are commonly designed for straightforward disassembly. Be aware, however, that certain models may use sealed components requiring specialized tools or expertise. It’s wise to examine the construction of your specific model before attempting disassembly.

Consulting the original manufacturer’s guidelines provides insight into disassembly feasibility. If manufacturer recommendations are unavailable, observing similar models and their designs can also guide your decision. Thus, verifying model compatibility is crucial prior to beginning your disassembly.

HOW OFTEN SHOULD SOLAR LIGHTS BE MAINTAINED?

Periodic maintenance of solar lights is advisable to ensure optimal functioning. A general recommendation is to inspect them bi-annually. Such intervals allow for thorough cleaning, component checks, and battery replacements as necessary. Maintenance checks typically should coincide with seasonal changes as environmental factors significantly impact device efficiency.

During these assessments, examine the solar panel for debris or dirt, evaluate wiring for signs of wear, and confirm that bulbs function correctly. Performing maintenance minimizes the likelihood of unexpected failures and prolongs the lifespan of the unit, making it a valuable investment.

CAN SOLAR LIGHTS BE REPAIRED, OR DO THEY NEED REPLACEMENT?

Many solar lights can indeed be repaired, particularly if issues arise due to batteries or wiring problems. Understanding the nature of the malfunction is paramount. Common repairs involve battery replacements, circuit reconnects, or fixing connections.

If extensive damage is observed, such as broken solar panels or motherboard issues, replacement may be unavoidable. Carefully weighing costs on components versus overall replacement of the entire unit helps guide this decision. Ultimately, evaluating repair feasibility based on specific damage types can foster informed choices, ensuring functional efficiency.

Engaging in both the disassembly and assembly processes of mini solar lights presents challenges that can be surmounted with the right tools and knowledge. Taking the time to gather necessary tools, such as screwdrivers and pliers, provides a solid groundwork for starting. Following through with careful disassembly sets the stage for valuable inspections and repairs of internal components. This effort ensures that every part is clean and functioning at its optimal level, significantly enhancing the lifespan and performance of the solar light. The reassembly phase, if performed meticulously by following documentation and visual guides, can yield impressive results in restoring a device back to usability. Ultimately, establishing a routine for maintenance fortifies the longevity of investment in solar lighting, asserting engagement in responsible upkeep that benefits both the environment and economical illumination solutions. The satisfaction derived from successfully repairing a solar light further instills a sense of accomplishment, encouraging future endeavors in home repairs or DIY projects. Thorough preparation fosters a sustainable approach to using energy-efficient lighting technologies effectively.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-and-assemble-a-mini-solar-light/