Here is the requested article based on the provided title.

1. DISASSEMBLING A SOLAR VACUUM

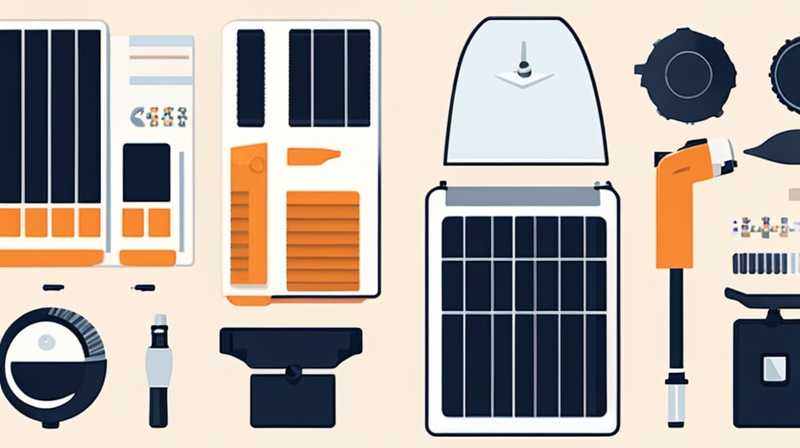

Disassembling a solar vacuum requires careful steps to ensure the process is both safe and effective. Key steps include 1. gathering necessary tools, 2. understanding the structure, 3. following a systematic approach, 4. taking safety precautions. Each of these aspects plays an important role in successfully taking apart the device, as improper handling can result in damage or injury. Focusing on the first point, it is essential to have the right tools ready, which may include screwdrivers, pliers, and possibly a socket set. Ensuring that these items are accessible will streamline the entire disassembly.

2. CONTENT OF THE SOLAR VACUUM

Understanding the basic structure and functionality of a solar vacuum is crucial before attempting disassembly. A solar vacuum typically comprises several components such as the vacuum tube, the heat pipe, and the manifold. The vacuum tube is responsible for absorbing sunlight efficiently, whereas the heat pipe transfers heat to the storage system. Every part of this assembly must be taken into account when planning to dismantle it.

Knowing how these components work in harmony aids in understanding the disassembly process. For instance, if the focus is simply on replacing a broken tube, isolating parts without affecting the heat pipe is essential. Careless disassembly can lead to complications or even necessitate a complete replacement of the solar vacuum unit.

Proper disassembly can extend the life of the solar vacuum and improve system efficiency when reassembled correctly. Moreover, knowing the materials involved is vital; cheaper models may use plastic whereas higher-end types tend to rely on glass and metal. This knowledge will guide expectations when executing repairs or upgrades.

3. TOOLS REQUIRED FOR DISASSEMBLY

Equipping oneself with the appropriate tools simplifies the dismantling process significantly. Essential items often include but are not limited to flat-head and Phillips-head screwdrivers, pliers, a utility knife, a wrench set, and safety goggles. It’s wise to gather the appropriate tools ahead of time to avoid interruptions during the process. Specific tools can vary based on the design and manufacturer, so referencing the product’s manual for particular requirements is prudent.

A flat-head screwdriver may help in prying apart components without causing damage. A Phillips-head screwdriver typically serves to loosen screws that hold elements together, while pliers can assist in tightening or loosening stubborn pieces. Additionally, wearing safety goggles is non-negotiable. This precaution protects the eyes from small particles or fragments that may dislodge during the process.

After ensuring all tools are prepared, reviewing the assembly of the solar vacuum is beneficial. Scanning the arrangement of parts can facilitate a systematic approach that leaves room for organized reassembly. Understanding which parts depend on one another can greatly minimize potential complications during disassembly.

4. SAFE DISASSEMBLY STEPS

Following safety steps is crucial to mitigate risks during the disassembly of a solar vacuum. Before initiating the process, confirm the device is disconnected from any power source. Emergency measures like turning off solar systems or disconnecting batteries cannot be overlooked. Neglecting to do this can result in shock or other dangerous incidents. Additionally, if the model has chemical elements such as refrigerants, handling them requires extra caution.

Next, consider wearing protective clothing, such as gloves and long sleeves, to protect against sharp edges or potential burns from hot components. Ensure that the workspace is clear and well-lit, thus reducing the likelihood of accidents. Proper ventilation in the work area also aids in avoiding exposure to harmful fumes or particles.

Once these precautions are established, begin with detaching any external components before diving into the core assembly. Removing panels or outer tubes prior to accessing inner elements promotes a clearer view and a less chaotic working environment. It’s also beneficial to keep organizational tools like containers to hold screws and small parts, thus preventing loss or confusion.

5. DISASSEMBLING THE MANIFOLD

The manifold, serving as an essential junction in the solar vacuum setup, requires attentive disassembly. Begin by identifying the screws or bolts securing it. It is advisable to take photos of each step for reference later. Use the appropriate screwdriver to remove mounting hardware cautiously. Since these are generally subjected to exposure, they may require extra force to loosen due to rust or corrosion.

Once the manifold is detached, inspect for any lingering connectors or hardware that may still be attached. Easing the manifold away from the vacuum assembly ensures that no surrounding parts are inadvertently damaged in the process.

Examine the manifold for any residue, dirt, or obstructions while it is removed. Cleaning it now can enhance the performance of the solar vacuum once reassembled. Addressing any critical repairs can also prolong the functional life of the overall system. Once satisfied with the manifold’s condition, it’s time to proceed further with the disassembly of other core components.

6. REMOVING THE VACUUM TUBES

The next integral phase involves detaching the vacuum tubes. This stage may vary considerably depending on the design specifics of the unit in question. Generally, each tube will be secured at both its inlet and outlet, often with rubber gaskets or seals. It’s critical to remove these seals gently to avoid tearing; a utility knife may assist in achieving this, but it should be used with caution.

As tubes are extracted, paying attention to their condition is wise. Cracks or signs of wear can indicate the necessity for replacements, so keeping note of their status is beneficial. Moving methodically through each tube’s removal helps maintain organization within detached components.

Additionally, washing vacuum tubes is advisable at this stage, as debris may accumulate post-removal, risking the system’s efficiency during reassembly. Employ warm soapy water and a soft cloth to remove build-up delicately, mindful not to scratch glass tube surfaces. Once the tubes are dismantled adequately and cleaned, secure them safely away from additional components to prevent any scratches or damages on surfaces.

7. DETACHING THE HEAT PIPE

Disengaging the heat pipe necessitates an understanding of its integral role in thermal management. Often, these items can be secured with bolts or clamps that should be manipulated carefully to maintain the component’s structural integrity during removal. Grasp where the heat pipe connects to the vacuum tube assembly to alleviate stress on other interconnected components.

Upon removing the heat pipe, it’s essential to keep it upright; this part may still contain residue that could leak if positioned otherwise. Inspect the heat pipe for potential flaws or leaks. Any deficiencies might call for immediate replacements during the reassembly process, making note of what replacements are needed crucial to reducing downtime.

With all parts disengaged, having visual references or a checklist aids in ensuring the return of everything into the correct alignment upon reassembly. Handling each piece with care promotes a longer lifespan for the solar vacuum system, enabling predictable efficiency once it returns to regular operation.

8. REASSEMBLY CONSIDERATIONS

When considering reassembly post-disassembly, systematic organization plays a pivotal role. Each component should be returned to its original placement, and it is optimal to revert in reverse order of disassembly. Using earlier photographs serves as a visual guide that reinforces memory, ensuring precision in the return process.

Additionally, taking the time to inspect each part before reassembly is crucial. This period allows for repairs or cleaning to take place without delaying overall functionality once the solar vacuum returns to service. It’s also wise to replace any worn seals or gaskets to prevent leaks that could impact performance.

Once every component is examined and deemed ready for reattachment, aligning parts accordingly ensures each piece fits seamlessly. The use of torque specifications, referred to in the product manual, assists in knowing how tightly to attach screws or bolts.

Finally, double-checking connections and the overall assembly guarantees nothing has been left loose or improperly connected. Engaging in a thorough inspection before returning the solar vacuum to operational status protects against future complications and enhances overall effectiveness.

FAQs

1. HOW OFTEN SHOULD A SOLAR VACUUM BE DISASSEMBLED FOR MAINTENANCE?

Scheduled maintenance is essential for the optimum performance of a solar vacuum. Regular intervals suggest checking the unit at least once or twice a year. Each solar vacuum’s environmental exposure may necessitate more frequent assessments, particularly in regions experiencing severe weather conditions, which can induce wear and tear. Assessing components periodically improves performance efficiency and prolongs the device’s lifespan.

During each maintenance session, owners should inspect the vacuum tubes, manifold, and heat pipe thoroughly. Observing for signs of damage, leaks, or blockages is critical to preserving the efficacy of the unit. If necessary, disassembly aids in cleaning or replacing critical components that show any form of degradation.

Neglecting these assessments can lead to decreased efficiency, as dirt or blockages accumulate over time. Some solar vacuum owners may be inclined to perform more frequent checks to remain proactive, especially when utilizing the unit heavily or in unpredictable weather conditions. Awareness of unit specifics and regular evaluation equates to an environment of care and responsibility within solar technology.

2. CAN ANYONE DISASSEMBLE A SOLAR VACUUM, OR SHOULD IT BE DONE BY A PROFESSIONAL?

While some individuals possess the skills and technical knowledge to disassemble a solar vacuum, engaging a professional is often wise. Professionals equipped with the necessary training and experience ensure that disassembly aligns with manufacturer specifications. This expertise becomes particularly significant when it comes to specialized models or intricate designs that may present challenges to the average user.

However, for those with a solid understanding of tools and assembly mechanics, and who are comfortable tackling minor repairs, self-disassembly is feasible. Acquiring careful instruction from manuals and observing guidelines can facilitate a rewarding experience. For substantial repairs, or if any uncertainty arises concerning handling the unit, consulting an expert might save time and mitigate risks.

Balancing competence with caution remains paramount. Assessing whether it is better to consult a professional depends on the complexity of the disassembly and the familiarity of the individual with solar vacuum systems. In areas of uncertainty, leaning towards professional assistance can foster confident decision-making.

3. WHAT REPLACEMENT PARTS MIGHT NEED TO BE CONSIDERED DURING DISASSEMBLY?

Numerous parts may necessitate replacement during the disassembly of a solar vacuum. Key replacements often include vacuum tubes, seals, and perhaps the heat pipe if any flaws are present. Given the operational context of solar vacuums, exposure to various elements may cause routine wear, thus making replacements vital for sustained efficiency.

Vacuum tubes often face cracks or other forms of damage, particularly in harsh environmental conditions. These tubes are critical for optimal sunlight absorption, thus affecting overall thermal performance if flawed. Gaskets and seals typically require replacement as well, given that aging and constant thermal expansion can compromise their integrity, leading to air leaks or moisture ingress.

Additionally, the heat pipe may present issues, particularly if it shows signs of excess heat or compromise. Addressing any of these aspects during disassembly is a proactive measure to ensure the longevity and functionality of the solar vacuum system. Being aware of prevalent weaknesses allows for a systematic approach to maintaining the overall performance of the device.

Bold taking apart a solar vacuum can offer numerous rewards when executed with care and skill. Through meticulous planning, utilizing appropriate tools, and implementing safety precautions, individuals can enjoy an improved understanding of their device while extending its lifespan. Each step taken contributes to a more sustainable future as solar technology continues to evolve. Emphasizing the importance of maintenance means not only fostering awareness of potential flaws and weaknesses but also inspiring responsible care towards renewable energy technologies. Incorporating further research and personal experiences can enhance knowledge for future endeavors, solidifying a foundation for advancing personal skills in the realm of solar energy.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-a-solar-vacuum/