1. SOLAR TRANSISTOR DISASSEMBLY: UNDERSTANDING THE PROCESS

Disassembling a solar transistor requires careful attention to detail and a systematic approach. 1. Gather necessary tools, 2. Identify connection points, 3. Safely separate components, 4. Understand the internal structure. One crucial aspect of this procedure is to prevent any damage to sensitive electronics during disassembly. Proper tools, such as small screwdrivers, pliers, and anti-static wristbands, are essential to ensure control over the process and protect the photovoltaic elements.

2. GROUNDING AND PREPARATION FOR DISASSEMBLY

Correctly preparing the workspace and establishing grounding practices is vital before embarking on the disassembly journey. Various tools often become necessary, including screwdrivers, pliers, and an anti-static wristband. The disassembly area should be free from clutter and distractions, allowing for focused examination of the solar transistor’s structure.

Safety remains paramount, and grounding oneself is a preventive measure to avoid static electricity that can damage electro-sensitive components of the solar transistor. To achieve this, an anti-static wristband should be worn; this connected mechanism directs any static electricity safely away from the working environment. Organizing the identified tools and ensuring they are within reach matters significantly for enhancing efficiency during the disassembly stages.

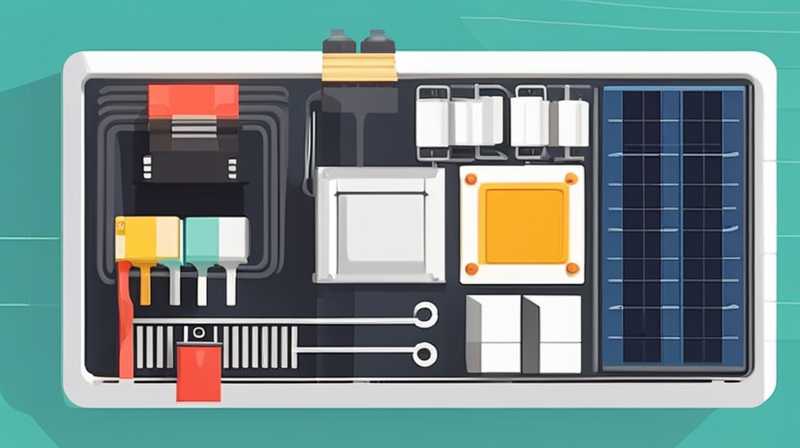

Familiarity with the solar transistor’s anatomy is equally pivotal during this procedure. Transistors often consist of three main sections: the collector, emitter, and base. Understanding these components helps guide the disassembly, indicating which parts need removal first. Visual references, such as diagrams or manuals, can provide additional insight into the specific transistor type being dismantled, thereby facilitating the process further.

3. IDENTIFYING COMPONENTS AND CONNECTION POINTS

To deconstruct a solar transistor, identification of elements and their corresponding connections is vital for a successful undertaking. The solar transistor generally features leads that can be soldered, connected through clips, or secured with screws. Recognizing these connections prevents mishaps while separating components and contributes to a successful disassembly experience.

Before proceeding, familiarize oneself with the schematic representation of the solar transistor. Identifying essential components such as the gate, source, and drain, among others, will offer insights into potential attachment points worthy of examination. For instance, noting whether the transistor is a field-effect type or bipolar junction type allows for an efficient approach when processing its disassembly.

Once the connections are understood, using precision tools to detach each individual connection without damaging surrounding elements is paramount. Gentle, methodical movements help alleviate accidental breakage of components. Care should also be taken not to pull on leads forcefully, which can often lead to damage. Ultimately, understanding and recipe identification builds confidence and competence to continue with the disassembly process.

4. DISASSEMBLY PROCESS: SEPARATING COMPONENTS SAFELY

Executing the disassembly of a solar transistor necessitates a combination of patience, dexterity, and keen attention. Starting with the exterior casing, gently leverage open the housing with precision tools such as plastic prying tools, which minimize any potential harm to the components inside. During this initial stage, awareness remains crucial; the goal is to avoid scratching or damaging the solar panel’s surface or the circuit board.

Once the casing has been successfully opened, examine and document the interior layout. This documentation helps track the connections made between various components and serves as a useful reference for reassembly or repairs in the future. Take note of any abnormalities in wiring or solder points, and assess if they could impact functionality after being reassembled.

As the work progresses, be mindful of adhesive components that may require heat application to soften, allowing for easier separation. Setting a controlled heat source, such as a heat gun or soldering iron, provides a useful method to melt adhesive materials carefully. After the heating process, provide sufficient time for components to cool down prior to handling them, ensuring that both user safety and component integrity are maintained throughout the disassembly.

5. REASSEMBLY AND TESTING POST-DISASSEMBLY

Successfully disassembling a solar transistor often leads to the necessity of reassembly after inspection or repair work. To initiate this, it is crucial to follow the documented notes taken earlier and systematically reverse the disassembly process. Begin reattaching components and leads, ensuring that all solder points or connection clips are secure yet not over-tightened, which may lead to further difficulties later.

Once components are reconnected, it’s beneficial to conduct preliminary tests to assess functionality. Using multimeters helps check voltage levels and determine if the components are working according to their specifications. Careful monitoring during this phase can ultimately prove necessary, as discovering issues at this juncture can prevent further complications during usage.

After successful reassembly and testing, ensure that the housing is securely reassembled, and double-check that no components are left detached or misplaced. Lastly, document any alterations or adjustments made during the disassembly and reassembly process to serve future reference aid or maintenance support. A methodical approach during the complete cycle not only promotes a successful experience but solidifies expertise in handling solar transistor technologies.

FREQUENTLY ASKED QUESTIONS

1. WHAT ARE THE COMMON TOOLS REQUIRED FOR DISASSEMBLING A SOLAR TRANSISTOR?

The necessary toolkit for dismantling a solar transistor can vary depending on the specific model; however, some essential tools are commonly utilized across the board. Primarily, precision screwdrivers (particularly tiny sizes) are indispensable for loosening screws without damaging threads or heads. Furthermore, pliers, such as needle-nose types, are handy for gripping, bending, or gently applying pressure on delicate connections throughout the procedure.

In addition, having an anti-static wrist strap ensures safety from static electricity, which can destroy sensitive electronics during manipulations. This device functions by providing grounding, thus dissipating any potential electrical charges that may interfere with the components. Consider also keeping a spudger or plastic pry tool on hand to help separate components gently without scratching sensitive surfaces.

Moreover, utilizing a multimeter is beneficial during both disassembly and reassembly phases. This tool allows users to measure parameters such as voltage, current, and resistance to verify that components are functioning correctly prior to reconnection. Lastly, a workspace free from clutter and distractions aids in maintaining focus throughout the delicate disassembly process.

2. HOW DO I SAFELY DISASSEMBLE A SOLAR TRANSISTOR WITHOUT DAMAGING IT?

Ensuring the safe disassembly of a solar transistor hinges on several best practices. Primarily, adopting a methodical approach is crucial. Begin by preparing the workspace adequately—clearing surfaces and ensuring all tools are easily accessible sets the stage for a calm and efficient disassembly phase. It is equally vital to examine the device thoroughly prior to taking any actions. This initial assessment allows for a clearer understanding of the component layout and connection points.

When dealing with exterior casings, employ gentle leveraging techniques using plastic pry tools, as metal implements may scratch or nick sensitive surfaces. Always avoid applying excessive force, which can damage not only the casing but the internal components as well.

Moreover, patience plays an instrumental role throughout the disassembly process. Rushing through disassembly can lead to missed connections or the possibility of snapping leads. It’s essential to take breaks if the process feels overwhelming, allowing for pauses where focus can be regained and errors avoided.

Lastly, documenting each step with notes or sketches helps maintain clarity regarding how components interconnect. Following these guidelines meticulously promotes safer handling and enhances overall competence during the disassembly of solar transistors.

3. WHAT CAN BE DONE IF A COMPONENT BREAKS DURING DISASSEMBLY?

Encountering a broken component during the disassembly of a solar transistor can indeed be disheartening. However, several avenues can be pursued to address such issues. First and foremost, maintaining composure is paramount; panicking can lead to further damage or mishaps. The initial step should involve assessing the extent of the damage to gauge whether repair or replacement is necessary.

If the broken component is repairable, using appropriate tools and techniques may restore functionality. For instance, small circuits can often utilize soldering solutions to reconnect broken parts, easing the reattachment process. Furthermore, utilizing epoxy or appropriate adhesives can sometimes temporarily mend fractured pieces until a more permanent solution can be figured out.

Should the component be irreparably damaged, replacement parts become the default choice. Identifying genuine manufacturer parts, or seeking alternatives from reputable sources, ensures that the replacements meet necessary specifications for functionality. Upgrading to improved components may also become a viable option when addressing a break; this can lead to enhanced performance overall and contribute to more reliable usage of the solar transistor.

Ultimately, learning from the disassembly event contributes to growth; future handling can be approached with care, reducing the chances of experiencing similar difficulties again.

EMERGING INSIGHTS AND ABSORBING KNOWLEDGE THROUGH THE EXPERIENCE

Disassembling a solar transistor entails a meticulous, systematic approach that significantly enhances one’s comprehension of its internal workings. By conducting a thorough examination prior to disassembly, gathering appropriate tools, and maintaining a patient manner, a practitioner can navigate the intricacies of the process effectively. The knowledge gained not only reinforces technical expertise but also boosts confidence in handling future electronics. This activity embodies both a technical challenge and an opportunity for personal growth, serving as a valuable learning experience for both novices and experts alike. As individuals work through the disassemblyprocedures, they cultivate deeper sentiments regarding technology, craftsmanship, and nurture appreciation for renewable energy systems. Ultimately, the success of disassembly and reassembly hinges on a balanced formulation of preparation, execution, and application—leading to a fulfilling journey in the realm of solar electronics.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-a-solar-transistor-2/