The intricate process of dismantling a solar heat preservation barrel is centered on several critical steps that, when followed carefully, can lead to a successful and efficient task. 1. Understanding the composition of the barrel, 2. Utilizing appropriate tools, 3. Adhering to safety protocols, 4. Systematically disconnecting components are essential to ensure proper handling. Emphasis should be placed on understanding how the components interact with each other and recognizing any potential hazards involved in this process. For example, the barrel’s insulation and fittings may contain materials that require special handling, making it crucial to approach the task methodically. Addressing these points will ensure both safety and effectiveness throughout the disassembly.

1. UNDERSTANDING THE SOLAR HEAT PRESERVATION BARREL

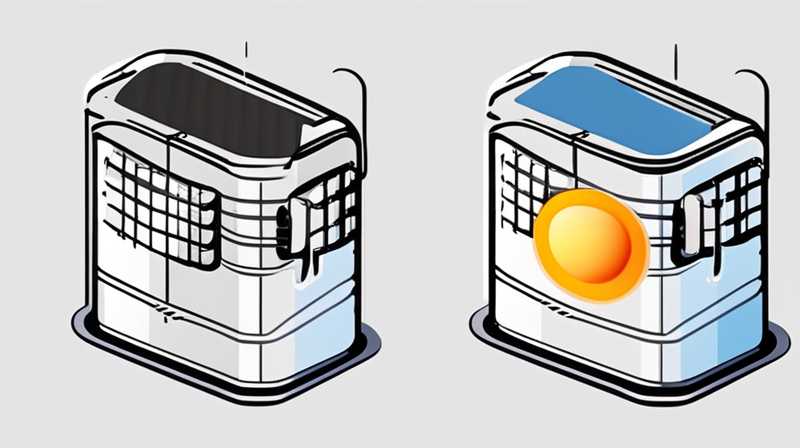

Before initiating the disassembly of a solar heat preservation barrel, it is imperative to gain a profound comprehension of its structure and purpose. Typically, these barrels are designed to store heated water effectively through solar energy harnessing. A deeper examination reveals that these vessels often consist of several layers, including an outer casing, insulation material, and the internal compartment for water storage. Knowledge of this composition not only provides insights into how to dismantle it but also emphasizes the importance of certain materials during disposal.

The insulation layer, commonly made from foam boards or fiberglass, plays a crucial role in energy retention. Understanding its properties aids in handling it safely and responsibly. When removing the barrel, one must consider how the structure supports temperature retention and how insulation degrades over time. This knowledge will inform the disassembly approach, ensuring that all materials are handled under the correct guidelines.

2. UTILIZING APPROPRIATE TOOLS

Equipping oneself with the right set of tools is pivotal to ensuring a seamless disassembly process. Common tools might include screwdrivers, wrenches, pliers, and possibly a utility knife for cutting through any adhesives or seals. Specialized tools such as a multimeter may also be necessary for disconnecting electrical components safely. Having these tools organized before initiating the task can significantly enhance efficiency and safety.

The condition of each tool must be carefully evaluated. For instance, using a screwdriver that is too small might lead to stripped screws, complicating the disassembly process and possibly damaging the barrel. Similarly, rusty or worn tools increase the risk of accidents or injuries during manipulation. Prior preparation, including cleaning and inspecting tools, can make all the difference between a smooth operation and an arduous ordeal.

3. ADHERING TO SAFETY PROTOCOLS

Safety cannot be overstated when it comes to disassembling a solar heat preservation barrel. Adhering to safety protocols protects both the individual conducting the disassembly and anyone in the vicinity. Appropriate personal protective equipment (PPE) such as gloves, goggles, and masks should always be worn, especially since insulation materials can release harmful fibers when disturbed.

Furthermore, ensuring a well-ventilated workspace is essential, particularly if the barrel contains any residual chemicals from prior use or potential hazardous materials hidden within the insulation. It’s advisable to familiarize oneself with the Material Safety Data Sheets (MSDS) that accompany any insulating materials. These documents provide crucial information about the safe handling and disposal of materials, mitigating the risk of exposure to harmful substances.

4. SYSTEMATICALLY DISCONNECTING COMPONENTS

Once the groundwork is laid, the actual disassembly begins. Start by turning off any plumbing or electrical connections linked to the barrel. Depending on the model, it may be necessary to drain the water or fluids stored within before proceeding. This step is not just a precaution, but also a significant aspect of the disassembly process. Water left in the barrel can lead to unintended spills or accidents.

As each component is disconnected, it is highly beneficial to keep an organized inventory of parts. This inventory can be extremely useful for troubleshooting or if one plans to reassemble the barrel in the future. Proper labeling of screws and parts, along with taking photographs, can serve as a reference to ensure that steps are not missed during reassembly. Completing this step thoughtfully can save considerable time and frustration.

5. HANDLING INSULATION MATERIALS

The insulation materials used within solar heat preservation barrels can vary, and their handling requires particular attention. For example, fiberglass insulation, though effective for heat retention, can pose health risks if proper precautions are not taken. When removing these materials, it’s crucial to handle them gently to minimize airborne particles.

Disposing of insulation must also adhere to local regulations. Improper disposal can lead to environmental harm or legal consequences. Investigating local waste management options for disposal of such materials ahead of time ensures compliance and environmental stewardship.

6. REASSEMBLY AND REUSE

After successful disassembly, one might wonder about the possibilities of reusing certain components. Reassembly is feasible if all parts remain intact and in good condition. Many individuals choose to repurpose these barrels as rainwater catchment systems or even for composting. Assessing each component’s condition allows for creative solutions rather than simply discarding them.

Moreover, being environmentally conscientious during this step is vital. Rather than disposing of functional parts, consider donating them to community projects or local workshops. This not only reduces waste but also fosters a culture of recycling and sustainability within the community.

FAQs

WHAT TOOLS ARE REQUIRED FOR DISMANTLING A SOLAR HEAT PRESERVATION BARREL?

To dismantle a solar heat preservation barrel, ensuring you have the proper tools is essential for efficiency and safety. Typical tools required include screwdrivers, wrenches, and pliers for unscrewing and detaching various parts of the barrel. Depending on the model, you might also need a utility knife for cutting through adhesive seals or insulation. A multimeter can be handy if the barrel is connected to electrical components, allowing you to safely disconnect these without risking shocks.

Using the right equipment not only simplifies the process but also minimizes the risk of damage to both the barrel and its components. Inspecting tools for wear and tear can make a significant difference, ensuring that a good condition leads to effective service. Well-maintained tools enhance safety, making the entire disassembly experience smoother.

HOW DOES ONE ENSURE SAFETY DURING THE DISASSEMBLY PROCESS?

Safety considerations are fundamental when embarking on the disassembly of a solar heat preservation barrel. Proper personal protective equipment (PPE) like gloves, goggles, and masks shields against potential hazards such as insulation materials that can release harmful fibers. Furthermore, working in a well-ventilated area reduces risks associated with inhaling any dust or fumes.

Familiarity with Material Safety Data Sheets (MSDS) for insulation materials or other components assists in understanding potential health risks and safe handling practices. Prior preparation, such as reviewing safety procedures and having an organized workspace, greatly minimizes the chances of accidents occurring during the dismantling process. Safety should underpin every step.

WHAT CAN BE DONE WITH DISASSEMBLED PARTS?

After the disassembly process, there are several options for dealing with the various components of a solar heat preservation barrel. Many individuals choose to repurpose parts for different applications, such as converting the barrel itself into a rainwater collection system or using smaller components in DIY projects. Before disposal, consider evaluating each part for functionality and possible reuse.

Additionally, certain materials, especially metals, may carry scrap value and can be recycled effectively. Searching for local recycling centers can provide options for responsible disposal. Engaging with community groups or local initiatives is another method to donate functional parts, contributing to sustainability. Seeking innovative solutions for discarded materials fosters creativity and reduces waste.

The intricate task of dismantling a solar heat preservation barrel encompasses numerous pivotal steps that ensure safety, efficiency, and reusability. Proper understanding of the barrel’s components forms the foundation for proceeding with disassembly. Moreover, utilizing the right tools minimizes risks and enhances effectiveness, while safety protocols safeguard the individual undertaking the task against potential hazards. Systematic disconnecting of components allows for clear organization and management throughout the disassembly. The responsible handling of insulation materials ensures environmental compliance and health safety. Following disassembly, evaluating component reusability promotes sustainability and creative thinking. Each of these factors collectively interlocks to offer a comprehensive guide for an effective dismantling process. Proficiency in these areas not only underscores the significance of preparation and care but also emphasizes a broader responsibility towards environmental implications. Therefore, the disassembly of a solar heat preservation barrel stands as a conscientious endeavor that balances practical action with innovative thinking and adherence to safety. The journey, though technical in nature, yields fruitful outcomes not just for individual purposes but also within communal context.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-a-solar-heat-preservation-barrel/