To disassemble a small solar light strip, follow these steps: 1. Gather tools such as a screwdriver and pliers, 2. Identify the screws or clips holding the casing, 3. Remove the casing carefully without damaging internal components, 4. Disconnect the wiring from the solar panel and LEDs, 5. Separate the battery compartment, and 6. Keep track of all components for reassembly or replacement. It is essential to be cautious, particularly around the electrical components, to avoid any damage or injury.

1. UNDERSTANDING THE SOLAR LIGHT STRIP

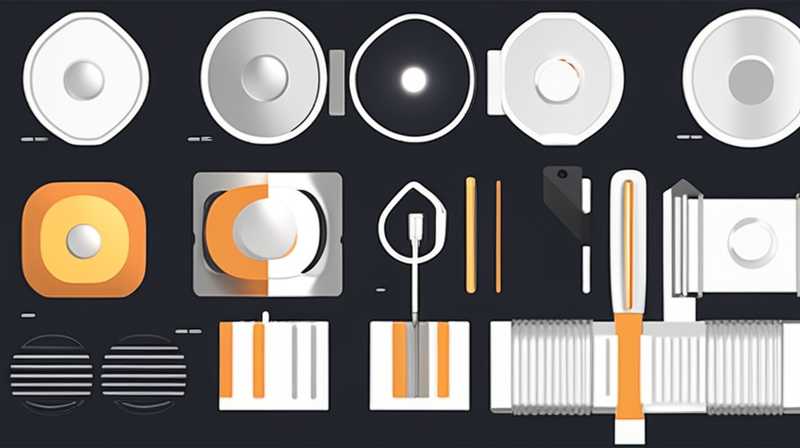

Solar light strips have gained immense popularity due to their functional versatility and environmental benefits. These devices convert sunlight into electrical energy through embedded solar panels, which power the LEDs, providing illumination without relying on conventional electricity sources. Understanding the fundamental construction of a solar light strip is essential. The assembly typically consists of a protective casing, solar panels, LED lights, batteries, and wiring. This design allows for seamless integration into various applications, including outdoor lighting, pathway illumination, or decorative purposes.

Disassembling a solar light strip can stem from several reasons, including maintenance, repair, or upgrading components. The process of disassembly is not solely about breaking it down; it involves understanding how each piece interacts within the entire system. Often, failure in one component leads to complete malfunction, necessitating thorough inspection. Addressing the components one by one during disassembly provides insights into both the function and potential enhancements of the device.

2. GATHERING THE NECESSARY TOOLS

Before initiating the disassembly of a solar light strip, procuring the appropriate tools is crucial. Basic tools usually required include a flathead screwdriver, Phillips screwdriver, pliers, and possibly a utility knife. Each of these tools serves a unique purpose, helping achieve a clean disassembly without damaging surrounding elements. For instance, screwdrivers are essential for loosening screws that secure the outer casing, while pliers can assist in disconnecting tight wiring configurations.

Ensuring the work area is well-lit and organized can significantly reduce the chances of losing small components. A magnetic tray can be particularly useful for holding screws and other tiny parts during the process. Having everything at hand minimizes interruptions, allowing for a smoother dismantling experience. An organized approach encourages careful handling of the light strip and becomes beneficial when reassembling or replacing any faulty components.

3. EXAMINING THE EXTERIOR CASING

Upon gathering the necessary tools, the next step involves closely examining the exterior casing of the light strip. Most solar light strips feature an outer shell made from plastic, which protects the internal components from environmental factors. The casing may be held together by various screws or clips, which vary by manufacturer. Recognizing the specific type of fastening system is essential, as improper handling can lead to permanent damage.

Using a screwdriver, begin by locating the screws securing the casing. Once located, carefully remove each screw and set them aside in an organized manner. If clips are present, gently press or pull them to release the casing without forcing it. Patience is critical at this stage, as rushing can cause cracks or breakage. Upon successfully removing the outer layer, further investigation into the internal components becomes possible.

4. DISCONNECTING WIRING COMPONENTS

With the casing removed, focus shifts to the internal wiring connections. These connections link critical components such as the solar panel, LEDs, and batteries. It is essential to handle these wires delicately to avoid severing them or causing short circuits. Most connections will either be soldered or connected via plug-ins, meaning familiarity with these types will guide effective disassembly.

When unplugging connectors, ensure to pull on the connector itself rather than the wire to avoid damage. For soldered connections, a soldering iron may be necessary to detach wires. Always remember to check the polarity of connections before detaching them for easier reassembly later on. Documenting the original layout through photographs or sketches can assist in recollection. Proper disconnection of wiring is vital for proceeding to separate the individual components.

5. REMOVING THE SOLAR PANEL

Once wiring is disconnected, attention can shift to the solar panel unit. The solar panel is usually mounted firmly within the casing, and care must be exercised to avoid bending or damaging it. Depending on the design, the solar panel may be fixed with screws or adhesive. Identifying the mounting system in use is necessary for efficient removal.

If screws hold the solar panel in place, remove them with the designated screwdriver. In cases where adhesive is employed, a utility knife can be carefully used to pry it loose. Ensure to apply minimal force to prevent damaging the panel. After securely detaching the solar panel, it can be set aside for inspection or replacement. At this point, a complete view of how components interact can be appreciated, facilitating further decisions regarding upgrades or enhancements.

6. SEPARATING THE BATTERY COMPARTMENT

Following the removal of the solar panel, focus shifts to separating the battery compartment. Batteries store the harvested energy for later use and are often housed in a dedicated compartment for accessibility and safety. Standard configurations may include rechargeable NiMH or Lithium-ion batteries, which need to be treated cautiously during disassembly.

To access the batteries, look for screws or clips securing the battery compartment within the housing. After loosening these fasteners, gently pull the compartment out. It may be necessary to disconnect wires linked to the battery to fully extract it. Awareness of battery polarity is crucial during reconnections to prevent malfunctions. Once the battery compartment is separated, it can be inspected for corrosion or damage, leading to power inefficiencies.

7. INSPECTING LED LIGHTS

After ensuring the battery compartment has been safely extracted, the focus changes to the LED lights. LEDs constitute the crucial illumination source within the solar light strip and evaluating their condition is pivotal. Inspecting for physical damage, discoloration, or burnt-out diodes can immediately inform whether they require replacement or if the issue lies elsewhere within the assembly.

LEDs can typically be disassembled from their holders without much hassle. In most light strips, they are either soldered or embedded within a circuit board. If soldered, leaning on a soldering iron will be required for their removal, while receptacle-type connections allow for easier detachment by simply pulling them out. Observational skills are vital to also check if any wiring connected to the LEDs needs replacing or if they are functioning correctly.

8. FOCUSING ON POTENTIAL UPGRADES

Upon accomplishing the disassembly of all components, attention can be directed toward potential enhancements. Many users opt for upgrading batteries, changing LED types for more efficient models, or installing improved solar panels. Recognizing that technological advancements can lead to significant performance improvements empowers owners to breathe new life into their solar light strips.

Replacement parts must be compatible with the existing configurations to ensure seamless integration. Researching specific components, such as higher-capacity batteries or brighter LEDs, can yield information necessary for achieving desirable outcomes. Planning upgrades allows for sustainability while contributing positively to energy savings. Each modified component contributes to a more efficient system, enhancing functionality and longevity.

9. REASSEMBLY PROCESS

After intentional disassembly and consideration of upgrades, attention must now focus on the reassembly of the solar light strip. Following the reverse order of disassembly can streamline this process, providing an organized approach to reconstructions. Arranging components can aid in identifying any missing pieces or overlooked connections. Employing the photographs and sketches created earlier will assist in this step, achieving accuracy and functionality.

Start with the LED lights and reattach them either by soldering or using their respective connections. After ensuring they are securely in place, reinsert the battery compartment and its wiring, making certain polarity aligns correctly. Reattachment of the solar panel follows, reinforcing connection integrity before securing the outer casing. Once completed, recheck each connection to ascertain reliability and functionality.

10. TESTING FOR FUNCTIONALITY

As the reassembly completes, verifying functionality stands as a critical step. Testing the solar light strip ensures that all replacements or upgrades operate as intended, confirming performance and efficiency. Place the light strip outside to allow it to gather sunlight, activating sensors or switches that might be in place for operation.

After a full charging cycle, observe the performance of the light strip at night. Ensure that illumination reaches the desired levels and check if the device operates consistently. If any issues arise during this phase, revisit the disassembly steps to rectify shortcomings. Testing emphasizes the success of the disassembly, effectively affirming one’s technical capabilities while enhancing appreciation for the technology involved.

WHY DISASSEMBLING IS IMPORTANT

Disassembling a small solar light strip is a practical task with numerous benefits. Firstly, it allows for maintaining and prolonging the life of the light fixture, addressing wear and tear that occurs over time. Secondly, it opens the door to repair defective components rather than replacing the entire unit, which can be much costlier. Finally, the disassembly process provides an opportunity to learn about the technology behind solar lights, fostering an appreciation for renewable energy devices.

Additionally, as technology evolves, components may become outdated. Instead of purchasing a new unit, disassembly permits integration of contemporary enhancements, boosting energy efficiency and illumination quality. Among the main challenges of disassembling is ensuring no part is lost or damaged, which underscores the need for careful handling and documentation throughout the process.

SOLAR LIGHT STRIP DISASSEMBLY STRATEGY

Disassembling a solar light strip, while requiring concentration and systematic approach, can be rewarding. This does not necessarily require a high degree of technical knowledge, as most homeowners can accomplish this task with a few tools, patience, and the guidance provided. Through the outlined steps of understanding, gathering tools, examining components, and reassembly, one can effectively maintain and upgrade their solar light strip for optimal performance.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF BATTERIES ARE USED IN SOLAR LIGHT STRIPS?

The batteries most commonly used in solar light strips include Nickel-Metal Hydride (NiMH) and Lithium-ion models. NiMH batteries are favored for their sustainability, affordability, and capacity to withstand multiple charge-discharge cycles, making them a prevalent choice among solar light manufacturers. However, Lithium-ion batteries, with their higher energy density and longevity, are emerging as best users for more advanced solar light functions.

When considering replacements, a buyer should ensure that the intended battery fits well within the existing compartment and matches the voltage requirements. Understanding the programmable capacities of each battery type can lead to better decision-making, enhancing overall solar strip efficiency over time. Regular checks for battery condition will enable one to identify the right time for replacement, further allowing for cost-effective maintenance.

HOW OFTEN SHOULD I DISASSEMBLE MY SOLAR LIGHT STRIP FOR MAINTENANCE?

Regular maintenance is essential for ensuring the longevity of devices like solar light strips. An ideal timeframe for disassembly and inspection would be once or twice a year, with a closer inspection after severe weather events such as storms or heavy snow. This practice helps identify worn or defective components before they cause significant functional loss, allowing for timely repairs or upgrades.

During these inspections, one should check for corrosion in the battery compartment, dirt or debris on the solar panels, and the state of the connections leading to LEDs. By addressing these areas proactively, the efficiency and reliability of the solar light strip can be maintained indefinitely. Close attention will ensure the device functions optimally and meets the user’s lighting needs.

CAN I CHANGE THE LED LIGHTS IN MY SOLAR STRIP?

Absolutely, upgrading or replacing the LED lights in a solar light strip is a feasible and common practice. When considering changing LED types, one should ensure that the new lights match the voltage and configuration of the existing ones to avoid connectivity issues. There are various options available, including brighter and more energy-efficient models which enhance the performance of the lighting system overall.

To change the LED lights, it may require some soldering knowledge if the components are connected directly to the circuit board. Before making any changes, it’s prudent to evaluate the overall system to ensure no other aspects will be negatively impacted. Post-upgrade, conducting functionality tests will confirm that all energy-efficient enhancements have been successfully integrated into the solar light strip setup.

The disassembly and subsequent maintenance of a small solar light strip serve as crucial steps in prolonging its functionality and efficiency. Engaging in the process empowers individuals to tackle technical issues directly, fostering a deeper understanding of renewable energy devices, and paving the way for possible upgrades. The undertaking ultimately reinforces both technical skills and appreciation for sustainable technology. Recognizing that solar light strips are not merely light sources, but rather, embodiments of innovation and environmental sensitivity, encourages users to invest the necessary effort for optimal performance. Each disassembly session not only rejuvenates the device but also enhances one’s confidence in managing and improving renewable technology, all while promoting sustainability through effective energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-a-small-solar-light-strip/