To disassemble a double-sided single-crystal solar light, one must follow a systematic approach to ensure safety and efficiency. 1. Gather necessary tools, 2. Ensure safety precautions, 3. Identify components, 4. Carefully disassemble in reverse order of assembly, 5. Store components safely for reuse. A key aspect of this process involves ensuring that all tools, like screwdrivers and pliers, are ready to avoid interruptions. The critical safety measure is to disconnect the solar light from any power source before starting the disassembly, as this will prevent any electrical hazards. One must also note that meticulous organization of the various components is essential for a successful reassembly if needed.

1. TOOL PREPARATION AND SAFETY MEASURES

Disassembling a double-sided single-crystal solar light requires specific tools to avoid damage during the process. Essential tools typically include a flathead screwdriver, Phillips screwdriver, needle-nose pliers, and a soft cloth to prevent scratches on the solar panels. Having the right tools not only streamlines the disassembly procedure but also minimizes the risk of injury or damage. It is vital to ensure that the tools are in good condition; using damaged tools can lead to accidents, making safety a priority.

Proper safety precautions cannot be overstated. Ensuring that the solar light is disconnected from any electrical supply is crucial before initiation. This step protects the individual from any possible electric shock. Wearing safety goggles and gloves adds a layer of protection against any accidental sharp edges or debris that may come loose during the process. Taking a moment to ensure a clean, organized workspace can also aid in keeping track of small parts and tools.

2. UNDERSTANDING COMPONENTS OF THE SOLAR LIGHT

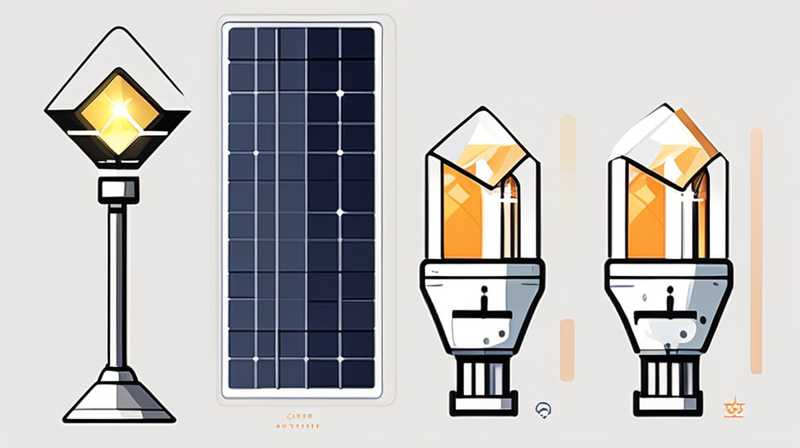

A double-sided single-crystal solar light consists of various parts that work together to capture sunlight and convert it into usable energy. Identifying each component is essential before moving on to the disassembly phase. The primary components include the solar panel, LED lights, battery pack, housing, and mounting mechanism. Understanding how these parts are connected will help determine the order in which they should be disassembled.

The solar panel, often comprised of single-crystalline silicon, is responsible for capturing solar energy. Knowing its placement and how it connects to the housing can prevent any potential damage during removal. LEDs provide illumination and their integrity is crucial; improper handling can result in burnt-out lights. Therefore, careful consideration should be taken to avoid stressing the wires or connections during the disassembly.

3. STEP-BY-STEP DISASSEMBLY PROCESS

When one begins disassembling the solar light, it is generally advisable to work from the outside elements inward. Start with removing the outer housing, which may be held in place by screws or clips. Using a screwdriver, gently unscrew any visible fasteners. If clips are in place, a flathead screwdriver can be used to pry them open carefully. It is important to note that excessive force may break either the clips or the housing, leading to more complex repairs.

After the outer housing is removed, pay attention to how the internal components are connected. Once the housing is off, one can gently disconnect the solar panel. Often, it will be attached via wires; these should be handled with caution. Always remember the arrangement and state of each connection, possibly taking photographs for reference during reassembly. It’s integral to place all screws and parts in a designated location to avoid loss.

4. REASSEMBLY AND TESTING

Having disassembled the solar light, if reassembly is the next step, the reverse order of disassembly should be followed closely. Reconnecting the solar panel, LED lights, and battery pack needs careful attention to avoid any incorrect connections. Each wire should be securely reattached to its corresponding component, ensuring no loose wires remain that could become a fire hazard.

Once the solar light is reassembled, it is essential to test its functionality. Placing the light in a location where it can receive adequate sunlight will confirm that the disassembly and reassembly processes were successful. Additionally, ensure that the LEDs illuminate appropriately during night hours, indicating an effective energy conversion.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD SOLAR LIGHTS BE DISASSEMBLED FOR MAINTENANCE?

Disassembly for maintenance purposes should not be a frequent task unless specific issues arise. Regular visual inspections can often identify problems without the need for disassembly. It is advisable to check the solar panels for dirt or debris, as this can hinder the light’s ability to absorb energy. Cleaning the panels gently with a soft cloth ensures optimal performance. In the event that the light shows signs of malfunctioning, such as dim lighting or complete failure, then disassembly will be necessary.

The choice to disassemble will depend on the solar light’s quality and the conditions of use. In harsher environments where the light receives exposure to dirt, moisture, or physical damage, disassembling may be needed more often to ensure all components are operating effectively. For long-term maintenance, an annual check-up should suffice for most conditions unless otherwise indicated by performance issues.

WHAT TO DO IF PARTS OF THE SOLAR LIGHT ARE DAMAGED DURING DISASSEMBLY?

In the unfortunate event that parts become damaged during disassembly, the specific course of action will depend on the part that was compromised. Researching replacement options is crucial; many components can be found online or through local hardware stores. For minor cosmetic damage, such as scratches on housing, one might consider using touch-up paint.

If the solar panel itself is damaged, it is vital to replace that part, as continued use can lead to further issues. When sourcing replacements, ensure they are compatible with the specific model of solar light to prevent further complications. This requires noting the specifications of the damaged part ideally before attempting any repairs.

HOW CAN I MAKE MY SOLAR LIGHT MORE EFFECTIVE?

Several strategies exist to help enhance the efficiency of solar lights beyond just the disassemble-and-repair method. Positioning the solar lights in areas that receive maximum sunlight exposure during the day is essential. Trees, buildings, or other obstructions should be minimized to ensure optimal light capture.

Regular maintenance is also vital. Cleaning solar panels every few months contributes to better energy absorption; dirt and grime can significantly reduce performance. Additionally, ensuring the surrounding area is free from debris will further aid in maximizing efficiency, especially during winter months when snow accumulation can block light sources.

In closing, disassembling a double-sided single-crystal solar light is a meticulous process that requires careful attention to detail, proper tools, and an understanding of the components involved. It begins with adequate preparation involving both tools and safety measures. The disassembly itself necessitates a systematic approach to ensure that all components—such as solar panels, LED lights, and housing—are adequately managed throughout the process. Moreover, if issues arise during disassembly, fully aware individuals can quickly identify what replacement parts may be needed. Ultimately, knowledge of the system ensures that reassembly is straightforward, preserving performance and longevity. Maintaining solar lights also involves regular inspections and cleaning, allowing for sustained effectiveness over time. As technology continues to evolve, understanding these aspects will lead to a more efficient usage of renewable energy sources. Embracing this maintenance practice not only enhances personal experience but contributes to broader environmental efforts as well.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-a-double-sided-single-crystal-solar-light/