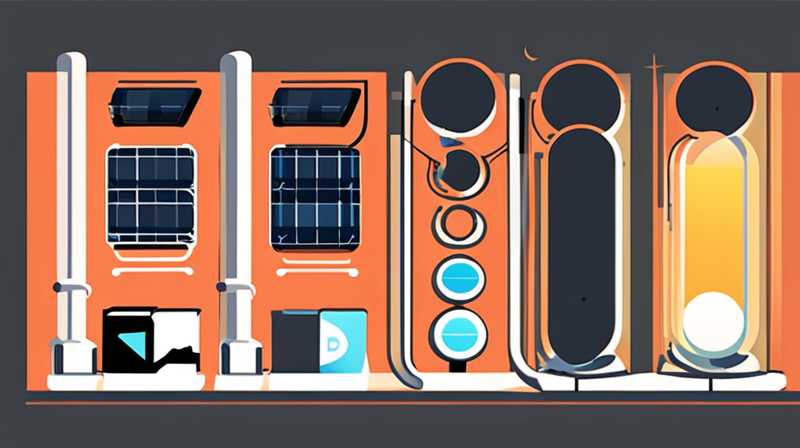

To detect solar tube failure, several indicators and methods can be utilized effectively. 1. Visual Inspection, 2. Monitoring Temperature Changes, 3. Pressure Testing, 4. Performance Evaluation. Visual inspection involves examining the tubes for physical damage, while monitoring temperature changes helps identify performance inefficiencies. Pressure testing assesses the system’s integrity, and performance evaluation compares output with expected results.

DETECTION METHODS

VISUAL INSPECTION

The initial step in identifying potential failures in solar tubes is a thorough visual inspection. Inspectors should look for cracks, discoloration, or signs of physical wear, which can be indicative of compromised structural integrity. Particular attention should be paid to the connections and seals; even minor defects in these areas can lead to significant failures. Additionally, checking for any visible obstructions, such as dirt or debris, can prevent accumulation that may hinder performance.

Once the external conditions of the solar tubes have been assessed, building owners should focus on the installation points and their accessibility. Proper installation is critical, and any signs of incorrect installation, such as poorly positioned tubes, should raise alarms. In some instances, the angle or orientation of the tubes may not be optimal, which can greatly affect performance. Keeping communication open with installers or manufacturers can provide insights into what to look for during these inspections.

MONITORING TEMPERATURE CHANGES

Another effective method of detecting solar tube failure is through monitoring temperature changes. Solar tubes are engineered to convert solar energy into heat efficiently, and a deviation from expected temperature levels signals potential issues. Utilizing temperature sensors or data loggers, one can capture temperature readings at different times throughout the day. This allows for an accurate assessment of system performance and its ability to capture and retain heat.

When discrepancies arise—such as abnormally low temperatures—it is crucial to investigate further. Investigating the cause might entail inspecting the fluid circulating within the system, as well as examining valves and pumps. Any abnormalities in heat transfer efficiency can indicate a failure in the system. Analyzing the flow rates of the heat transfer liquids may also provide crucial information on whether the system is functioning optimally or experiencing blockages.

PRESSURE TESTING

Pressure testing serves as another critical means to detect solar tube failure. The core principle behind this method is that a properly functioning solar tube system should maintain a specific pressure range. Deviations from typical pressure values can indicate leaks, blockages, or even structural problems.

When performing a pressure test, it is essential to isolate the system from the rest of the plumbing. One can use a pressure gauge to monitor levels, looking closely for any rapid drops, which would signal a leaking area. Employing this technique regularly not only aids in detecting failures swiftly but also mitigates more severe complications down the road. Detecting pressure deficiencies can help in early intervention, which is critical in extending the system’s lifespan and ensuring optimal functionality.

PERFORMANCE EVALUATION

An essential aspect of identifying solar tube inefficiencies lies in comprehensive performance evaluation. This involves comparing the energy output and heat retention against established benchmarks based on the installation’s specifications. Over time, solar tube systems should demonstrate consistent output values, and any significant drop can indicate impending failure.

To perform this analysis effectively, one can calculate the energy generation based on sunlight exposure and the location of the installation. Comparing this output to historical performance metrics can help ascertain potential delays or declines in energy collection. Additionally, factors such as weather conditions and seasonal changes must be integrated into these evaluations to provide a comprehensive overview of system health. Identification of any discrepancies can lead to timely diagnostics and repairs.

MAINTENANCE TIPS

REGULAR SYSTEM CHECKS

Incorporating regular system checks into operational protocols is paramount. By conducting frequent servicing and systematic evals, one can maintain optimal operation and swiftly identify early signs of failure. Experts recommend performing annual or biannual inspections to avoid minor issues from becoming significant failures.

During these checks, it is prudent to ensure that all components, including insulation, tubing, and valves, adhere to standards. Faults identified early can often be fixed with minimal downtime and expense. Additionally, ensuring that all fittings and connections are secure can eliminate unnecessary risks associated with potential leaks.

UTILIZING MONITORING TECHNOLOGIES

Adopting modern monitoring technologies can enhance detection measures significantly. For example, integrating software applications that analyze performance data and report changes in real-time can offer valuable insights. These technologies enable quick responses to anomalies, reducing the likelihood of experiencing severe failures.

Leveraging advanced monitoring can lead to improved maintenance practices as well. Systems equipped with sensors provide continuous data streams, allowing operators to make informed decisions based on real-time analysis. Many of these solutions offer alerts when deviations occur, ensuring swift action can be taken.

INCREASING KNOWLEDGE AND AWARENESS

TRAINING PERSONNEL

An integral part of ensuring solar tube efficiency lies in the training and knowledge of personnel responsible for maintenance and operation. Providing comprehensive training on system mechanics and potential failure indicators equips individuals to react promptly to early warning signs of issues.

Organizations should prioritize the development of training programs that cover both basic and advanced troubleshooting techniques. By instilling a culture of continuous learning, staff can identify anomalies with greater accuracy and speed, thus avoiding costly downtime.

CREATIVE PROBLEM SOLVING

Innovation should be encouraged within the maintenance teams when dealing with detection and problem-solving approaches. Technicians familiar with diverse systems may provide alternative solutions and greater understanding of correlation between design aspects and operational results.

By fostering a mindset that embraces creative solutions, organizations can gain deeper insights into systemic weaknesses. Additionally, open lines of communication allow for ongoing dialogue regarding issues encountered by various teams, which can further enhance detection capabilities.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON SIGNS OF SOLAR TUBE FAILURE?

Common indicators of solar tube failure include visible damage to the tube surface, inadequate performance levels, and significant drops in heat transfer efficiency. Inspectors should look for signs such as cracks, leaks, or discoloration, which could point toward compromised structural integrity. Furthermore, sudden fluctuations in temperature readings or output levels compared to expected benchmarks may also indicate failure. Keeping abreast of these warning signs helps ensure the longevity and efficiency of solar tube systems.

HOW OFTEN SHOULD SOLAR TUBES BE INSPECTED?

Ideally, solar tubes should undergo routine inspections at least once or twice yearly, depending on the climate and environmental factors. Seasonal changes like heavy rains or snow can impact the tube’s functionality, necessitating more frequent check-ups in certain areas. Regular inspections allow for early detection of issues that could escalate into costly repairs, thus maintaining operational efficiency. It is advisable to create an inspection schedule that aligns with climatic shifts for the best results.

CAN SOLAR TUBES BE REPAIRED IF FAILURE OCCURS?

In many instances, solar tubes can indeed be repaired if issues arise, provided that the damages are not too severe. Minor leaks or superficial cracks can often be patched, allowing the system to continue functioning. However, if core structural components or seals are compromised, it might be necessary to replace the tubes entirely. Evaluation by a qualified technician is essential to determine whether a repair is possible or if a full replacement is more appropriate for restoring efficiency.

FORMULATING A STRATEGY FOR MONITORING AND MAINTENANCE

Developing a proactive strategy for monitoring and maintaining solar tube systems is imperative. This involves not only regular checks and immediate attention to any warnings but also leveraging technology for real-time data analysis. Training staff extensively in both the operational aspects and potential pitfalls of the systems will facilitate timely interventions and mitigate risks associated with failures. Additionally, cultivating an environment where innovation and creative problem-solving thrive can lead to enhanced detection techniques and improved overall system performance. Each component plays a vital role in ensuring operational longevity and efficacy, highlighting the interconnected nature of these practices.

Ultimately, effective detection of solar tube failure hinges upon visual inspections, temperature monitoring, pressure testing, and performance evaluations, combined with strategic maintenance practices. Through consistent attention and advanced monitoring methods, long-term sustainability of these systems can be achieved while safeguarding investments related to renewable energy solutions. As the need for reliable solar energy becomes increasingly pressing, ensuring the functionality and performance of solar tube systems remains a priority for efficiency and efficacy in harnessing natural resources.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-detect-solar-tube-failure/