1. Understanding the Indicators of Debonding in Solar Cells, 2. Utilizing Visual Inspection Techniques, 3. Employing Advanced Diagnostic Tools, 4. Regular Maintenance and Monitoring Strategies

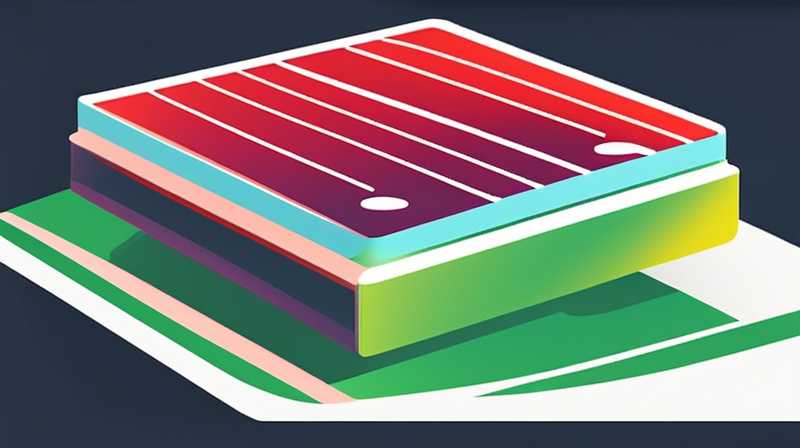

To determine the presence of debonding in solar cells, 1. observation of physical indicators, 2. implementation of non-destructive testing, 3. attention to performance metrics, 4. reliance on thermal imaging techniques are essential. Debonding occurs when the layers of a solar cell, particularly between the photovoltaic layer and the backing material, begin to separate. This phenomenon can lead to a reduction in energy efficiency, increased degradation rates, and ultimately, power loss. A critical point is that regular inspections combined with advanced diagnostic tools can help in identifying debonding early, thereby reducing the potential for extensive damage and costly repairs. Photovoltaic systems should be routinely checked to ensure that they are functioning optimally, and any signs of debonding should be addressed immediately to prolong the lifespan and effectiveness of the solar installation.

1. UNDERSTANDING THE INDICATORS OF DEBONDING IN SOLAR CELLS

Detecting debonding in solar cells starts with a comprehensive understanding of the physical indicators associated with the phenomenon. The separation of layers typically manifests as loss of adhesion, visible cracks, or discoloration. Each of these symptoms serves as a potential warning sign that should prompt further investigation.

Physical indicators can manifest through distortion and warping in the solar module. Thermal expansion and contraction that occurs naturally can exacerbate the separation if the materials are not adequately bonded. Inspecting for these signs should be a routine aspect of ongoing maintenance, helping to catch issues before they grow into significant problems. Regular visual checks can reveal small changes in the cell’s appearance, which might suggest deeper issues at play.

Another aspect to consider in observing debonding is the impact of environmental factors. Changes in temperature, humidity levels, and exposure to weather elements can influence how materials interact within the solar module. Thus, analyzing environmental conditions during inspections can provide insights into potential weaknesses in the bonding layers. This connection between environmental impact and debonding highlights the importance of being aware of local conditions and how they may affect solar cell integrity over time.

2. UTILIZING VISUAL INSPECTION TECHNIQUES

Visual inspection constitutes one of the most accessible and cost-effective methods for identifying debonding in solar panels. Effective visual scanning requires trained personnel who can identify signs of wear and tear that may go unnoticed by the untrained eye. Key areas to concentrate on include the edges of the panels, junction boxes, and connections between individual cells.

These trained inspectors utilize specific techniques in their evaluations. They often employ magnification tools to examine surfaces closely, looking for any signs of peeling, bubbling, or separation at the edges. The presence of water intrusion, which can signal significant debonding, also warrants attention. Regularly scheduled visual inspections can assist in proactively addressing issues and ensuring that any evident problems are documented and followed up with appropriate action.

Engaging in visual inspections should be complemented by lessons learned from past incidents of debonding. By reviewing case studies and reports from other installations, inspectors can expand their knowledge base and recognize atypical signs that might indicate debonding. Continued education in this field is essential, allowing inspectors to apply the latest techniques and knowledge in their assessments, ultimately improving the effectiveness of inspections and enhancing customer satisfaction when addressing solar integrity.

3. EMPLOYING ADVANCED DIAGNOSTIC TOOLS

The application of advanced diagnostic tools can significantly elevate the capacity to detect debonding in solar cells, especially when visual inspection only offers limited insights. Non-destructive testing (NDT) methods, including electrical resistance measurements and ultrasonic measurements, provide a robust framework for analyzing the integrity of solar cells without damaging them.

Electrical resistance measurements can pinpoint weaknesses by evaluating the flow of current through the solar module. Variations in resistance may indicate issues such as increased resistance in the joints and connections, which often correlate with debonding incidents. This electricity-oriented analysis allows for timely intervention, as addressing resistance issues directly can mitigate further degradation.

Ultrasonic testing serves as another advanced method. This technique sends sound waves through the solar module to detect inconsistencies within the material. Reflections and sound absorption patterns help determine whether layers of the module maintain their intended bond or if deterioration has occurred. Combining ultrasonic testing with electrical resistance assessments provides a holistic perspective on the health of solar cells, allowing for more accurate diagnoses.

4. REGULAR MAINTENANCE AND MONITORING STRATEGIES

Implementing a structured maintenance program can play a pivotal role in minimizing debonding occurrences in solar cells. Regular cleaning, along with prompt attention to any visible anomalies, should form the crux of such a program. Dust, debris, and other environmental contaminants can obstruct the efficiency of solar cells and indirectly affect the bond integrity over time.

Furthermore, scheduling inspections after significant weather events can be crucial. Storms, heavy winds, and hail can all introduce stresses that lead to debonding. By reinforcing the bond integrity through timely inspections shortly after such events, issues can be addressed promptly before they escalate. Hence, establishing a routine that encompasses varied weather conditions may yield beneficial results in maintaining solar cell integrity.

Adopting a performance monitoring strategy is equally important. Regular analysis of output performance data can indicate deviations from typical energy production patterns, raising flags regarding potential debonding issues. By correlating performance metrics with historical data, technicians can identify anomalies and take proactive measures before deterioration affects overall solar efficiency.

FAQS

WHAT ARE THE COMMON SIGNS OF DEBONDING IN SOLAR CELLS?

The most frequent indicators of debonding in solar cells include physical defects such as bubbles, peeling layers, and cracks. Changes in performance metrics can also serve as crucial signs that something may be wrong with the cells. For instance, a sudden drop in energy output, or energy yield irregularities, can signal that the layers are not functioning cohesively. Environmental conditions play a contributing role, so regular examinations are essential for determining the health of solar cells. Often, debonding is exacerbated by exposure to temperature fluctuations, moisture ingress, and extreme weather, which can cause the materials to interact differently over time. Additionally, it is advisable to regularly inspect physical changes, no matter how minor they may seem, as they serve as an essential part of overall maintenance protocols for solar energy systems. Prompt detection leads to timely intervention, which is fundamental in mitigating further damage and ensuring prolonged functionality.

HOW CAN I PREVENT DEBONDING IN MY SOLAR CELLS?

Preventing debonding involves adopting a multifaceted approach that combines several strategies aimed at maintaining solar panel integrity. Regular inspections and maintenance play a pivotal role in upholding conditions conducive to lasting bonds between materials. Inspecting the edges and critical junctions can identify small areas of concern before they escalate into bigger problems.

Environmental protection also dramatically reduces risks associated with debonding. Using appropriate coatings can protect solar panels from harsh UV radiation and moisture, both of which are detrimental. Furthermore, it is important to factor in the installation angle and positioning of panels while avoiding direct proximity to structures that might cast shadows or impede air circulation, as poor ventilation can trap heat and encourage delamination. Establishing a structured performance monitoring program can also help gauge early signs of potential debonding issues by pointing out any abnormalities in energy production or operational performance, thereby allowing for timely measures to be taken to address the root causes effectively.

WHEN SHOULD I SEEK PROFESSIONAL HELP FOR DEBONDING ISSUES?

Engaging professional help for debonding issues is warranted when visible physical signs or observable performance changes are noted. If inspections reveal crack formations, significant alterations in performance metrics, or if extensive environmental damage has occurred, it is crucial to consult with professionals who possess the expertise and appropriate diagnostic tools. Skilled technicians can provide a holistic evaluation and recommend an effective action plan.

It is also prudent to involve professionals during regular maintenance sessions, especially as the complexity of solar technology increases. Their insight can help assess not only the current state of the system but also forecast potential future issues. When significant weather events happen or if the system reaches a certain age, seeking an expert opinion can help identify hidden issues and ensure safety and operational efficiency. Their advanced diagnostic tools can pinpoint problems that may go undetected during standard visual inspections, leading to informed decisions that prolong the operational life of solar cells and prevent costly repairs.

The early detection and remediation of debonding issues in solar cells are integral for sustaining efficiency and longevity. Exploring various diagnostic options enables a comprehensive approach for maintaining solar energy systems, ensuring they contribute to sustainable energy solutions without unwarranted interruptions. The amalgamation of visual inspections, advanced diagnostic tools, and ongoing maintenance practices creates a robust framework for addressing potential debonding consistently. Unquestionably, empowering owners and technicians through preventive strategies and thorough understanding fosters advancements within solar technology. Moreover, aligning environmental factors with effective oversight can significantly reduce shortcomings related to debonding. As solar energy continues to develop, staying informed and proactive enables stakeholders to mitigate risks associated with debonding, ultimately fostering reliable and sustainable energy production for years to come. Implementing these practices will assure both efficiency and reliability from solar installations, thereby supporting larger goals in renewable energy use. Together, persistent efforts geared towards minimizing debonding risks will solidify solar power’s role as a critical player in global energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-detect-debonding-in-solar-cells/