Dealing with the drum inside a solar barrel necessitates an understanding of both the mechanical aspects and the overall functioning of the solar water heating system. 1. Identify the issue, 2. Assess the integrity of the drum, 3. Remove and clean the drum, 4. Reassemble correctly. Each step involves meticulous attention to detail to ensure optimal performance and longevity of the system. Notably, the cleaning of the drum is crucial because it can significantly affect the efficiency of the system. By ensuring that the drum is free from any residue or buildup, one enhances both the heat transfer capabilities and the overall performance of the solar heating system.

In understanding the nuances of effectively managing the drum inside a solar barrel, it is vital to explore the operational principles of solar heating systems, the specific role of the drum, and the common issues that can arise.

1. UNDERSTANDING SOLAR BARREL SYSTEMS

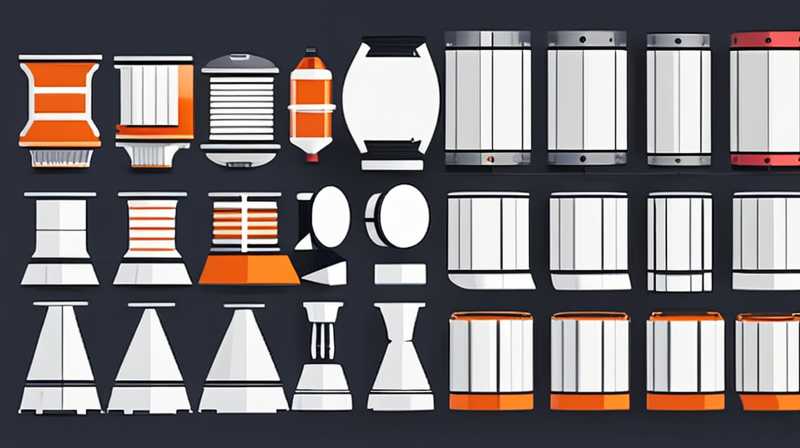

The solar barrel system serves as an integral component in solar water heating technologies. These systems utilize solar energy to heat water that can be used for domestic or industrial purposes. Understanding the mechanics of these systems is essential for dealing with any internal components, such as the drum. The drum acts as a reservoir where heated water is stored before use, and any issue here can significantly affect the overall functionality of the solar heating system.

One of the primary functions of the drum is to maintain a stable temperature for the stored water. The design of the solar barrel usually allows for stratification, where hotter water rises to the top while cooler water remains at the bottom. This stratification plays a crucial role in ensuring that hot water is available for immediate use without the need for additional heating. Understanding this principle allows one to appreciate the importance of keeping the drum in optimal condition.

The materials used in the construction of the drum are also critical to its performance. Most drums are made of materials that can withstand high temperatures and pressures. However, over time, these materials can degrade due to factors such as thermal expansion and contraction, exposure to corrosive elements, and mechanical wear. Recognizing potential material failures early can prevent more significant issues down the line.

2. COMMON ISSUES WITHIN THE DRUM

One of the most common challenges encountered is sediment buildup within the drum. This accumulation of minerals and debris can reduce the volume of water available for heating and diminish the efficiency with which heat is transferred to the water. Over time, sediment can also cause damage to the heating elements or the drum itself, leading to costly repairs or replacements. Understanding the causes of sediment buildup, such as hard water or inadequate filtration systems, can help in implementing preventive measures.

Another issue related to the drum inside a solar barrel is leaks. Leaks can arise from various factors, including corrosion, mechanical failures, or improper sealing during assembly. Not only do leaks decrease the efficiency of the system by allowing heated water to escape, but they can also lead to further water damage within the surrounding area. Regular inspection of the drum’s integrity is necessary to prevent significant leaks that could halt the entire operation of the solar heating system.

Identifying changes in the system’s performance can also indicate problems within the drum. For instance, if there is a noticeable decrease in the temperature or an increase in time taken to heat the water, it may signal that the drum requires attention. Keeping a watchful eye on performance metrics can help catch issues early, ensuring the system operates at maximum efficiency.

3. REMOVING AND CLEANING THE DRUM

The process of removing and cleaning the drum involves several methodical steps to ensure safety and efficiency. Before beginning, one must ensure that the solar barrel’s power supply is disconnected, and the water temperature is lowered to a manageable level to prevent burns or injuries. Once these precautions are in place, one can proceed to detach the drum from the solar system carefully.

Removal typically requires accessing a series of bolts or screws that secure the drum in position. Using appropriate tools for this job is crucial to avoid damaging any components during disassembly. Properly labeling each part as it is removed can facilitate easier reassembly later. After the drum is removed, a thorough inspection should take place to check for cracks, leaks, or other visible damage that might have occurred.

Cleaning the drum involves several techniques. A mixture of vinegar and water is often used to dissolve mineral deposits around the drum’s interior. This natural cleaning solution can effectively break down buildup without introducing harmful chemicals to the water system. Following the application of the cleaning solution, scrubbing with a non-abrasive brush can further assist in clearing away stubborn deposits. Once the interior is clean, rinsing thoroughly with water ensures no residues remain before reassembling the drum.

4. REASSEMBLING AND TESTING THE DRUM

Reassembling the drum requires a systematic approach to ensure all components are correctly reattached. Attention to detail during this phase is crucial, as improperly secured elements could lead to leaks or malfunctions once the system is back in operation. Each bolt or screw must be tightened according to manufacturer specifications to prevent stress on the drum’s structure.

Once the drum has been successfully reassembled, the next step involves conducting a series of tests to confirm that the system is functioning correctly. First, it is essential to re-establish the water supply and check for any signs of leaks. Observing how quickly the water heats and the maximum temperature achieved can provide insight into the system’s efficiency following maintenance.

Post-maintenance, monitoring the system over an extended period can highlight any persistent issues that may have been overlooked initially. Keeping detailed records of performance can help identify trends or recurring problems that require further intervention.

FAQS

WHAT ARE THE SIGNS THAT THE DRUM NEEDS MAINTENANCE?

Several indicators suggest that the drum within your solar barrel requires maintenance. 1. Reduced hot water availability, 2. Unusual noises during operation, 3. Visible leaks or damp spots around the barrel. When hot water is less available, it often indicates sediment buildup affecting efficiency. Unusual noises could point toward mechanical issues, such as failing components that may need immediate attention. Lastly, visible leaks suggest a problem in the drum’s integrity which could lead to more significant water loss and heating inefficiencies if left unchecked.

HOW OFTEN SHOULD THE DRUM BE CLEANED?

The frequency at which the drum should be cleaned can depend on various factors including water hardness and usage. However, a general guideline suggests cleaning every 1 to 2 years. In regions with hard water, more frequent cleanings may be advisable to prevent sediment build-up. Conversely, if the solar barrel is used only seasonally, once a year may suffice. Preparing a maintenance schedule will help mitigate problems and ensure optimum performance of the solar heating system.

CAN I PERFORM THE MAINTENANCE MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

Whether you choose to perform maintenance yourself or hire a professional can depend on your comfort level with mechanical systems. 1. DIY maintenance can save costs and provide hands-on experience, 2. Hiring a professional ensures expert attention and comprehensive service. If you have the skills and tools required, performing maintenance can be a rewarding experience, but it’s essential to follow instructions carefully. If you are unsure or lack experience, it may be more effective to contact a professional, as they will possess the expertise to address potential issues adequately.

Ensuring the optimal functioning of the drum in a solar barrel system is imperative for maximized efficiency and longevity. By identifying potential issues early, performing regular maintenance including cleaning, and ensuring proper reassembly, the lifespan of the solar heating system can be significantly extended. Moreover, understanding the underlying mechanics allows for informed choices about care and repairs. Engaging in hands-on maintenance not only enhances the system’s performance but also provides valuable insight into its operation, allowing users to develop greater respect and appreciation for renewable energy technologies. For many, the journey into solar energy is not just an environmental decision but also a step toward self-sufficiency and lower utility costs. Taking proactive measures with regular care enables individuals to enjoy a continuous supply of hot water while contributing to a greener planet.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-deal-with-the-drum-inside-the-solar-barrel/