Cutting the solar tube head involves several critical steps: 1. Precise measurements are essential, 2. Utilize the appropriate tools for clean cuts, 3. Follow safety protocols closely, 4. Review installation requirements post-cutting.

One of the most significant aspects of this process is the necessity for precise measurements. Accurate dimensions ensure a snug fit when the solar tube is integrated into your installation, ultimately enhancing the device’s efficiency and longevity.

1. UNDERSTANDING SOLAR TUBE HEADS

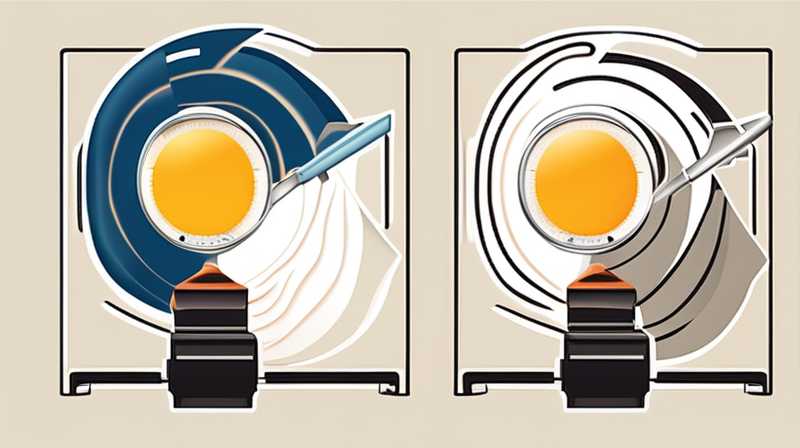

Solar tube heads serve as the critical connector between the solar collector and the tubes that gather sunlight. A comprehensive understanding of the components involved in solar tube technology assists in executing cuts accurately. The head typically houses the reflective surface and is integral in optimizing sunlight capture.

The effectiveness of solar tubes largely depends on their installation, which includes the configuration of the head. Thorough knowledge about the exact geometry and structure of the head will inform the cutting process. It’s imperative to familiarize oneself with the general dimensions and properties of the tube heads before proceeding to any modifications.

2. GATHERING NECESSARY TOOLS

Before undertaking the task of cutting the solar tube head, having the right tools is of utmost importance. Tools such as a fine-toothed saw, circular saw, or pipe cutter are often required, depending on the material from which the head is fashioned. Ensuring that the tools are specifically designed for the materials will guarantee that cuts are clean and effective.

In addition to cutting tools, having measuring instruments like a tape measure, caliper, and level can greatly enhance precision. A safety kit, including goggles and gloves, must also be at hand to avoid injuries during the cutting process. The old adage ‘measure twice, cut once’ rings particularly true here and emphasizes the significance of preparation.

3. MEASURING FOR ACCURATE CUTS

The next step in the process involves meticulous measurements that guide where cuts will be made. Ensuring the correct lengths and angles is vital. The tube head needs to accommodate the entirety of the solar tube while allowing for any additional features that may be part of the installation.

Using a measuring tape, measure the required lengths from a standardized point, preferably starting from the bottom of the head. Mark these measurements using a fine-tip marker or pencil that provides distinction without severe smudging. Incorrect measurements can result in a waste of materials and may endanger the entire installation, complicating the overall setup.

4. MARKING CUT LINES

After determining the necessary measurements, marking the cut lines comes next. Utilization of straight edges and framing squares can help create clear and precise guide lines. This stage is critical as it will direct the cutting process and directly affect the quality of the finished product.

Take your time during this step; a hasty approach can lead to skewed lines that ultimately cause irregular cuts. This attention to detail is paramount to ensure that the cuts will allow for smooth integration of the solar tube into the head. The importance of this phase cannot be overstated—it is the foundation upon which a successful installation is built.

5. CHOOSING THE CUTTING METHOD

Selecting the right cutting method should be based on the material of the solar tube head. Various options are available, like sawing and grinding, each with unique advantages and drawbacks. Moreover, the thickness of the head will determine whether a simple hand tool suffices or if a power tool is necessary.

For softer materials, a hand saw may be adequate, but more robust materials might require power saws or cutting torches. Review the specifications of the materials to select an appropriate tool, ensuring that you will achieve a clean cut that minimizes the risk of damaging the structure surrounding the head.

6. EXECUTING THE CUT

Once all previous stages have been correctly carried out, executive action is next. Secure the head safely using clamps or a vice to ensure that it remains stable during cutting, as a moving workpiece can lead to inaccuracies or injury. Work slowly and steadily; attempting to rush the process can compromise quality.

Maintain a steady hand and a clear focus throughout the cutting procedure. Consistency is key here, and any sudden movements can cause jagged edges or worse. Ensure that the saw blade or cutter is aligned precisely with the marked lines; follow them carefully, applying appropriate pressure without forcing the cut.

7. SMOOTHING THE EDGES

After achieving the desired cut, the next critical phase involves smoothing the edges. Frayed or jagged edges can impede proper fitting during installation, so utilizing a file or a sanding block can help achieve a clean, unobstructed edge. This step is often overlooked but is essential for a superior finish.

Take care during this phase to remove any burrs or imperfections by methodically working along the cut edges until they feel smooth to the touch. This is a meticulous job requiring attention to detail, but it contributes significantly to the overall quality of the project and aids in the longevity of the installation.

8. INSPECTING FINAL RESULTS

Conduct a final inspection of the cut solar tube head before proceeding to the installation phase. Ensure alignment with original specifications and dimensions to avoid complications later. Any noticeable deviations should be treated promptly—either by recutting or additional smoothing.

A thorough assessment will not only save time but also diminish frustrations during installation. It is imperative to take this step to confirm that everything aligns with the installation plan, allowing for effective functionality in gathering solar energy.

9. INSTALLATION CONSIDERATIONS

Once cutting and smoothing are complete, turn your attention toward the installation process itself. An optimized fit is crucial, ensuring that the solar tube head integrates seamlessly with the collector. Begin by verifying that all assembly points align properly.

Pay attention to the manufacturer’s guidelines, as they often provide specific instructions tailored for their models. Any adjustments needed to accommodate the cut head will need to be approached meticulously, ensuring that functionality is not compromised in pursuit of an improved fit.

10. MAINTENANCE TIPS POST-INSTALLATION

After successful installation, it’s essential to understand the maintenance tasks necessary for long-term functionality. Periodic checks for wear and tear, alignment, and seal integrity are beneficial, as they can preemptively catch potential issues before they escalate.

Protecting the solar tubes from harsh environmental conditions can also dramatically extend their lifespan. Using covers or shades when not in use may be advisable, depending on geographical factors. Understanding maintenance principles and proactively ensuring that all components are functioning optimally will ultimately enhance overall efficiency.

COMMONLY ASKED QUESTIONS

WHAT MATERIALS ARE SOLAR TUBE HEADS MADE FROM?

Solar tube heads are typically crafted from various materials, the most common being metal and plastic, each possessing unique advantages. Metal heads often offer enhanced durability and resilience against external factors, while plastic heads are generally lighter and more affordable. It is essential to evaluate the specific requirements of the solar installation when choosing the head’s material, as various climates and operating conditions will influence performance. Furthermore, advanced designs may incorporate composite materials, blending the strengths of different substances for optimized effectiveness. Understanding these material properties will guide users in selecting the right head for their specific solar tube application.

HOW DO I KNOW IF MY CUT IS STRAIGHT?

Ensuring a straight cut, particularly when dealing with the solar tube head, involves several practical techniques. Utilizing a straightedge tool in conjunction with measured guidelines can dramatically improve cut accuracy. If precision tools were used for marking, following those original lines closely during cutting minimizes deviation. After completing your cut, it is advisable to measure diagonal distances from the edges to ascertain uniformity; if the distances are equal, you have successfully made a straight cut. Consider using a level during the marking and cutting process to verify that the cutting face remains flat, providing assurance that the final product will fit the intended assembly.

CAN I REPAIR A BAD CUT ON MY SOLAR TUBE HEAD?

While repairing a miscut solar tube head is often challenging, it is feasible under certain conditions. If the errors are minimal, using filler compounds or resins can offer a workable solution, creating a more acceptable finish. Otherwise, unfamiliarity with the structure can lead to further complications, resulting in a potentially inefficient assembly. If the cut is significantly flawed, the most straightforward solution is to cut a new head from fresh material rather than attempting to salvage the initial attempt. A proper understanding of the head’s design will ultimately save time, as it allows for accurate cutting on the next iteration while maintaining functionality.

The process of cutting the solar tube head is intricate and requires careful attention to multiple factors for optimal results. Proper methodology and planning, starting from accurate measurements to the selection of tools and techniques, are critical for achieving a cut that meets installation requirements. Each phase must be executed with precision, from marking the cutting lines to ensuring a smooth finish and inspecting the final outcomes. These detailed steps contribute to an efficient and effective installation that maximizes the overall potential of the solar energy system. Moreover, considering long-term maintenance post-installation will further enhance the lifespan and functionality of the solar tubes. In essence, a thorough approach not only guarantees successful short-term outcomes but also assures longevity and performance efficiency in solar energy utilization. Each careful consideration significantly contributes to a well-executed solar installation, poised to harness renewable energy effectively. Therefore, thorough adherence to these guidelines transforms a seemingly daunting task into a manageable and satisfying project, ultimately fostering a sustainable future through effective utilization of solar technology.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-cut-the-solar-tube-head/