Cutting solar pipe fittings requires precision and the right technique to ensure a reliable and leak-free plumbing system. 1. Selecting the appropriate tools is crucial. Employ both cutting and finishing tools designed for the materials in question. 2. Adopting the correct cutting method prevents damage. Consider utilizing your hands for stability, and if applicable, a cutting guide for accuracy. 3. Measure carefully to maintain uniform lengths. Accurate measurements prevent waste and rework, ensuring optimal use of resources. 4. Post-cutting inspections are essential. Ensure that the edges are smooth and free of burrs to facilitate a proper seal during assembly. When using various materials, such as PVC or copper, pay attention to specific cutting techniques suited to each pipe fitting type. The choice of an appropriate cutting technique not only simplifies the process but also enhances the longevity of the fittings within the solar plumbing system.

1. SELECTING APPROPRIATE TOOLS

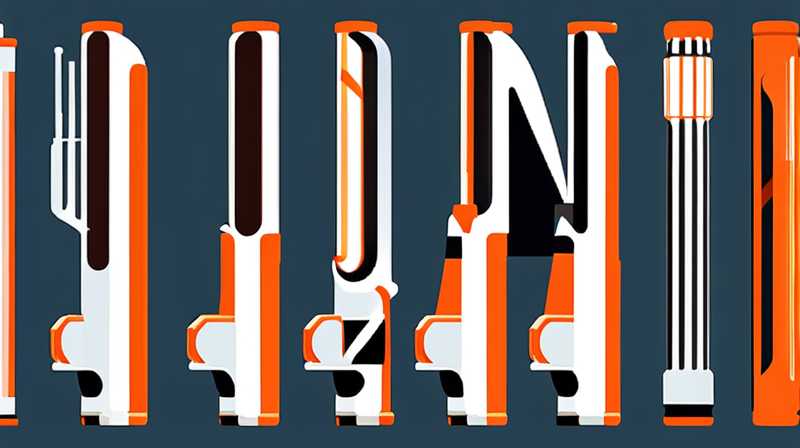

Choosing the correct instruments is fundamental when addressing solar pipe fittings. Conventional cutting tools might not yield optimal results with specialized materials typically used in solar installations. Common tools include pipe cutters, hacksaws, or reciprocating saws. Each has strengths suited for particular materials. For instance, a pipe cutter is excellent for clean cuts in thinner pipes, while a hacksaw provides flexibility and can handle diverse thicknesses and materials. Furthermore, for exceptional precision, tubing cutters are advantageous; they create neat, smooth edges without the risk of flaring or cracking, prevalent when using saws.

The emphasis should also lie on securing the fittings properly during the cutting phase. Employ clamps or vise grips to hold the pipe steady, minimizing movement that can lead to uneven cuts. When working with flexible tubing, such as PEX, dedicated cutting tools specifically designed to handle such materials can enhance efficiency and maintain integrity. Always ensure the tools are sharp, as dull blades force users to apply excess pressure, increasing the risk of damaging the fitting or injuring oneself.

2. ADOPTING THE CORRECT CUTTING METHOD

Utilizing the right cutting technique is paramount to achieving ideal results. Start by marking the pipe where the cut is desired. A marking pen or chalk can aid in creating a visible and precise guideline. Never attempt to cut too close to the mark; always leave a small margin for further adjustments if necessary. Begin the cut gently to avoid fractures that can commence from the edge of the cut. Establish a stable cutting posture to maintain control over the operation.

For larger diameter fittings, consider using a miter saw or bandsaw whenever feasible. This approach ensures that the cut remains straight and uniform. When using a hacksaw, keep the blade at a consistent angle and employ smooth, deliberate strokes. Maintaining a steady rhythm will minimize the likelihood of crooked cuts or breakage. Also, remember that braking the material in one continuous motion produces a cleaner cut than hacking or forcing through the material.

3. MEASURING CAREFULLY TO MAINTAIN UNIFORM LENGTHS

Measurements constitute a pivotal aspect of the cutting process, impacting the overall fit and function of the solar piping system. Begin by deciding the precise lengths required for each section, factoring in the fittings’ dimensions. A tape measure or a measuring stick can serve as reliable tools for acquiring exact measurements. After measuring, double-check to ensure accuracy; the phrase “measure twice, cut once” rings particularly true in plumbing applications.

When multiple identical lengths are necessary, leverage a template to mark several pieces simultaneously. Ensuring consistency throughout the system not only improves aesthetics but also enhances the overall reliability of the infrastructure. Any deviation in length may lead to problems during installation, such as poor connections or leaks between fittings. Investing time in the measuring phase streamlines subsequent installation efforts, saving cost and resources associated with wastage and reworking cut pieces.

4. POST-CUTTING INSPECTIONS

After successfully cutting solar pipe fittings, the next vital step lies in performing a thorough inspection of the cut edges. Rough edges and burrs can compromise the integrity of seals during subsequent assembly. Employ a file or deburr tool to smooth out any imperfections vigorously. When working with PVC or copper, removing burrs is imperative to ensure that the fitting seals are conducive to a durable system.

In addition, inspect the fittings for warping or other potential deformities arising from the cutting process. Such defects can also lead to leaks, which can be detrimental to solar systems relying on efficient fluid transport. A thorough inspections allow for identifying discrepancies before moving forward with installation, thereby creating a higher likelihood of achieving an effective and reliable plumbing solution. The cumulative attention to detail during the cutting phase, goes a long way in securing efficient energy performance from the installations.

FREQUENTLY ASKED QUESTIONS

HOW DO I CHOOSE THE RIGHT CUTTING TOOL FOR SOLAR PIPE FITTINGS?

Selecting the correct cutting tool significantly affects the outcome of your solar pipe fitting project. The choice depends on the material of the pipes in question, as various materials require distinct approaches. For metallic pipes, pipe cutters specifically engineered for metals will yield smooth cuts. In contrast, materials like PVC may necessitate a hacksaw or PVC cutter for an effective cut. Before finalizing a tool choice, consider the diameter of the pipe—it influences the required force and technique for achieving a precise cut. The objective is always to minimize damage while ensuring an acceptable edge quality.

Most importantly, ensure that your tools are in optimal condition. Dull blades or worn-out cutters not only compromise cut quality but may also increase injury risk due to excessive pressure exerted by the user. Opt for tools that allow for comfortable handling, providing precision control. Ultimately, investing in high-quality, specialized cutting instruments ultimately facilitates better installation and increases overall system reliability.

WHAT ARE COMMON MISTAKES TO AVOID WHEN CUTTING SOLAR PIPE FITTINGS?

Mistakes during the cutting process can greatly hinder efficiency and effectiveness in plumbing installations. One prevalent error is neglecting to measure accurately; improper measurements often lead to wasted materials and requires rework that is time-consuming and costly. As a general practice, always operate with a ruler or tape measure, marking cut lines with precision.

Another common oversight is the inadequate preparation of the workspace. Cluttered or unstable surfaces can result in inconsistent cuts and may lead to accidents. Always ensure that the area is organized, and tools are readily accessible. Finally, never underestimate the significance of post-cut inspections. Skips in this phase often lead to leaks and failures at critical junctions in the system. Inspect for burrs, imperfections, or warping post-cut to guarantee the longevity of your installation. Acknowledging these pitfalls allows for smooth, effective executions of your solar piping endeavors.

HOW CAN I ENSURE A PROPER SEAL AFTER CUTTING SOLAR PIPE FITTINGS?

Achieving a proper seal post-cut is essential for a leak-free plumbing system, directly affecting the overall efficiency of solar energy systems. After completing the cut, immediately verify the edge cleanliness by examining for burrs or rough spots. Utilize files or deburring tools to create a smooth, even edge—this is crucial for proper fitting alignment.

The right adhesives and sealants also play a pivotal role. Choosing the appropriate glue for the specific material can reinforce seals and secure fittings, preventing leaks or joint failures. It’s advisable to review manufacturer guidelines to understand the best bonding solutions tailored for particular pipe materials. Furthermore, when connecting fittings, apply uniform pressure to ensure a snug fit, leading to heightened durability and performance of the solar plumbing system. Consistent attention to sealing techniques fosters long-lasting and efficient installations.

ENSURING PROPER CUTTING OF SOLAR PIPE FITTINGS

Successfully cutting solar pipe fittings demands a blend of technical knowledge, precision, and suitable resource selection. It is critical to select suitable cutting tools based on material properties, ensuring clean cuts that facilitate effective assembly. The entire process hinges on precise measurements for maintaining uniform lengths to prevent costly mistakes during installation.

Moreover, post-cut inspections cannot be overlooked, identifying and rectifying imperfections that may impact functionality. Proper sealing techniques further reinforce the fittings’ integrity, ensuring that the solar plumbing system operates efficiently without leaks. Each cut, measurement, and fitting connection contributes to the overall energy savings and sustainability benefits of solar technology.

Recognizing the importance of each of these components allows for maximizing efficiency and reliability in solar installations. Failure to adhere to these guidelines can lead to suboptimal results, detracting from the intended benefits of harnessing solar energy. The cumulative effect of diligence and attention to detail during the cutting and installation phases ultimately assures a well-functioning, efficient system, significantly elevating the benefits derived from solar energy.

As industries continue to transition towards sustainable energy sources, mastering the finer points of installations—including the cutting and assembly of solar pipe fittings—becomes increasingly important. The insights provided here not only ensure robust installations but also contribute positively to the ongoing efforts of fostering environmentally friendly practices. Enhancing expertise in this area will empower installers to contribute effectively towards the advancement of renewable energy initiatives, thereby promoting greater adoption of solar technologies within communities.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-cut-solar-pipe-fittings/