To connect wires to small solar panels, follow these steps: 1. Identify positive and negative terminals, 2. Strip wire ends, 3. Connect appropriately, 4. Secure connections with connectors. The importance of properly identifying the positive and negative terminals cannot be overstated, as incorrect connections can lead to system malfunctions or damage. Ensure that all connectors are tight and insulated to prevent short circuits. Once you have completed the wiring, it is advisable to test the panel’s output using a multimeter to confirm functionality before integrating it into a larger array or system.

1. UNDERSTANDING SOLAR PANELS

Solar panels function through photovoltaic technology, converting sunlight into electricity. This process involves numerous interconnected solar cells, which absorb photons and release electrons, generating direct current (DC). Small solar panels have become increasingly popular due to their versatility and ease of use in various applications, from charging batteries to powering small devices.

When working with these power sources, knowledge of their construction and operational principles is essential. Photovoltaic cells are typically made of silicon, providing a robust material that yields high efficiency. The efficiency and suitability of small solar panels for specific tasks depend on factors such as the number of cells, their quality, and the panel’s overall size. Knowing how to connect them correctly can enhance their effectiveness and safety significantly.

2. TOOLS AND MATERIALS NEEDED

Before embarking on any solar panel connection project, possessing the right tools and materials is vital. Standard tools include wire strippers, crimpers, a multimeter, and protective gear such as gloves and goggles. The wires used must be appropriate for the panel’s size and voltage output, typically 18 to 20 gauge wire for small applications.

Proper preparation ensures a smoother process, minimizing potential errors during installation. Having connectors, heat shrink tubing, and electrical tape on hand can help secure and insulate your connections, further preventing short circuits or other electrical issues. Familiarity with local electrical codes and safety regulations can also provide invaluable guidance during the installation process.

3. IDENTIFYING POSITIVE AND NEGATIVE TERMINALS

The first step in connecting wires to small solar panels involves identifying the positive and negative terminals. Most panels have clear markings, often indicated with symbols like “+” for positive and “-” for negative. This identification is crucial, as reversing polarity can damage the solar panel or connected devices.

In the case of panels lacking clear indicators, utilizing a multimeter can assist in determining the terminals’ polarity. By measuring voltage output in sunlight, one can ascertain which terminal is positive. Ensuring correct identification forms the foundation for achieving a successful connection, preventing potential hazards associated with improper wiring.

4. STRIPPING AND PREPARING WIRE ENDS

Once terminal identification is complete, the next phase involves stripping the wire ends. Wire strippers simplify this task, allowing for precise removal of insulation to expose conductive copper strands. Stripping approximately half an inch from each wire is typically sufficient, but this can vary based on the specific connectors being utilized.

Preparation goes beyond simply stripping wire ends; it also involves ensuring that the exposed conductors are clean and free of corrosion. Any dirt, oxidation, or impurities can lead to poor connectivity and reduced performance. A clean connection is critical for maximizing electrical flow and ensuring the longevity of the solar panel setup. Taking the time to prepare wires adequately will yield significant benefits in performance and durability.

5. CONNECTING THE WIRE TO TERMINALS

With the wires appropriately prepared, you can proceed to connect them to the terminals. For most solar panels, using weather-resistant connectors such as MC4 connectors is highly recommended to ensure secure connections capable of enduring outdoor elements. Begin by pairing the positive wire with the positive terminal, followed by connecting the negative wire to the negative terminal.

Crimping is often the preferred method for securing these connections. The seating of each wire inside the connector should be sufficiently firm to prevent disconnection, especially during dynamic conditions such as shifting winds or accumulated solar heat. Always double-check the connections to verify the integrity of your work before finalizing the installation.

6. SECURING CONNECTIONS AND APPLYING INSULATION

After successfully connecting the wires to the corresponding terminals, the focus shifts to securing and insulating these connections. This step is vital to protect the exposed metal parts from environmental damages, including moisture, dust, and corrosion. Heat shrink tubing is an excellent way to insulate your connections, as it provides a tight seal when heated, making it effective against adverse weather conditions.

In addition to heat shrink tubing, electrical tape can be utilized to cover any exposed wire or connection. Proper insulation is essential to ensure the longevity of the installation, effectively preventing short circuits or system failures that might arise from unintended contact between metal components and moisture. A secure, insulated connection allows for optimal solar energy collection without concern for operational safety.

7. TESTING THE SOLAR PANEL CONNECTIONS

Following the connections and insulation, conducting thorough testing is paramount to verify that the solar panel system operates as intended. Utilizing a multimeter, measure the voltage output at the terminals. When exposed to sunlight, the readings should reflect the panel’s rated voltage, confirming functionality and proper wiring.

If the output is significantly lower than expected, or if there is no output, it necessitates a reevaluation of the connections. Verifying each connection and wire orientation can help identify potential issues. Additionally, checking for physical obstructions blocking sunlight from reaching the panel or ensuring there are no underlying electrical short issues can enhance troubleshooting efforts and ensure effective functionality.

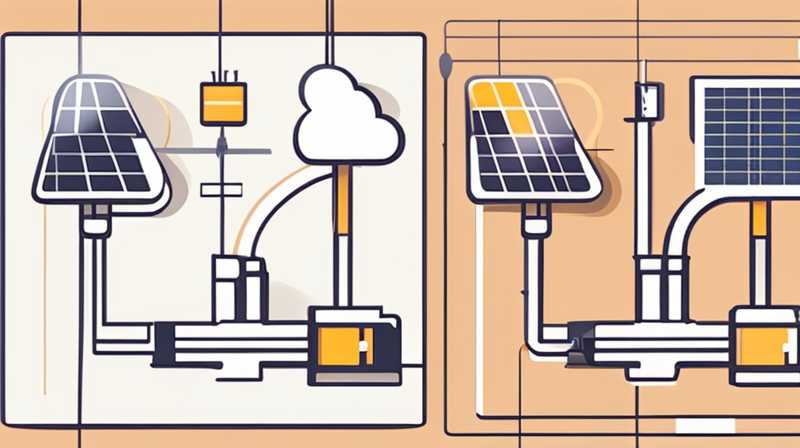

8. INTEGRATING WITH A SOLAR POWER SYSTEM

Having successfully connected and tested small solar panels, the next consideration often involves integration into a broader solar power framework. This setup generally includes the use of charge controllers and batteries, which regulate the voltage and store energy generated from solar input. Such configurations enable power generation even when sunlight is scarce, optimizing the flexibility of solar energy usage.

Understanding the compatibility of the panel with other components is crucial for ensuring a harmonious operation. Each component should be rated adequately regarding voltage and capacity, enhancing overall efficiency. Ultimately, careful consideration in the integration phase fosters a robust solar power system capable of meeting diverse energy demands reliably.

9. MAINTENANCE AND MONITORING

Regular maintenance of small solar panels and their connections is vital for sustaining high performance over time. Periodic checks will help identify any signs of wear and tear, dirt accumulation, or corrosion around terminals and connections. It’s advantageous to establish a routine that includes visual inspections and, when necessary, cleaning the panel surfaces to ensure optimal sunlight absorption.

Monitoring the output is equally important, particularly in the context of energy production. Keeping an eye on the voltage readings can promptly indicate potential issues, engaging in proactive measures to address any deviations from expected performance. Routine maintenance and monitoring foster a durable solar energy system that remains efficient in capturing and utilizing solar energy.

10. ADDRESSING COMMON ISSUES AND TROUBLESHOOTING

While operating small solar panels, various challenges may arise requiring careful troubleshooting. Common issues include low voltage output, fluctuating performance, or rapid discharging of connected batteries. Establishing a systematic approach toward identifying these problems is key.

For low voltage outputs, an inspection of connections is crucial, ensuring no loose or damaged wires affect performance. Exploring potential obstructions blocking sunlight from the solar panels can also be beneficial. For fluctuating performance, observing environmental factors such as shading from trees or debris is advisable. Addressing these common issues systematically enhances the reliability and endurance of small solar energy systems.

FREQUENTLY ASKED QUESTIONS

HOW MUCH POWER CAN SMALL SOLAR PANELS GENERATE?

The energy output of small solar panels can vary significantly based on size and design, typically ranging between 10 to 300 watts. Factors influencing output include panel efficiency, sunlight exposure, and weather conditions. While smaller models (around 10 to 50 watts) are suitable for charging batteries or powering small devices, larger units can provide significant energy for DIY applications. For example, a 100-watt panel can sufficiently charge a battery during peak sun hours. Ultimately, selecting an appropriate model depends on energy requirements and intended usage, ensuring alignment with overall power generation goals.

CAN SMALL SOLAR PANELS WORK IN CLOUDY WEATHER?

Indeed, small solar panels can still function in cloudy conditions, although efficiency may diminish. The photovoltaic cells can capture diffuse sunlight, converting it into electricity even with reduced direct sunlight. However, the energy output will typically be lower compared to bright, sunny days. On overcast days, it is common to see a drop in performance, but not to the extent that the panels stop generating energy altogether. Incorporating a battery storage system can assist in capturing energy produced on cloudy days, ensuring availability even when sunlight is limited.

WHAT TYPE OF BATTERY IS BEST FOR SOLAR SYSTEMS?

When choosing a battery for solar systems, several types can be considered, including lead-acid, lithium-ion, and gel batteries. Lead-acid options are more affordable, commonly used for various solar applications; however, they require regular maintenance and have a shorter lifespan. Conversely, lithium-ion batteries, while initially more expensive, offer higher efficiency, longer lifespans, and better performance under varying temperatures. Gel batteries provide another viable option, with distinct advantages in safety and longevity. The optimal selection often hinges on specific energy needs, budget constraints, and required performance levels, ensuring a suitable choice for individual applications.

Establishing a robust connection between wires and small solar panels can significantly influence efficiency and longevity. The meticulous attention paid to identifying terminals, preparing wires, connecting components securely, and insulating properly can help maximize electrical output while safeguarding against potential hazards. By nurturing a thorough understanding of all facets of the solar panel system, enthusiasts and professionals alike can navigate the path toward effective solar energy utilization. Investing in adequate tools, ensuring periodic maintenance, and embracing proactive troubleshooting strategies further enhances overall performance. The ultimate goal should be an efficient, safe, and reliable solar electricity generation stand that complements any project. Investing wisdom, patience, and adequate planning transforms the solar experience into a vibrant and sustainable endeavor, harnessing the power of the sun for daily energy needs.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-wires-to-small-solar-panels/