Connecting the wires of a solar check valve requires a precise approach to ensure proper functionality and safety. 1. Begin by gathering the necessary tools and materials. This includes wire strippers, connectors, and appropriate insulation tape. 2. Identify the solar check valve’s wire layout. Most systems will have clear markings that distinguish positive and negative terminals. 3. Strip the ends of the wires. Use wire strippers to carefully remove insulation from each end, ensuring the copper wire is exposed without damaging the strands. 4. Attach connectors securely. Use durable connectors to ensure a tight fit, preventing any loose connections that could lead to system failure. 5. Insulate the connections. Proper insulation is vital for safety and longevity; tightly wrap each connection with electrical tape to prevent moisture ingress. This detailed methodology guarantees that the solar check valve operates effectively, enhancing the efficiency of the solar energy system it supports. Following these guidelines will help establish a reliable connection that is essential for optimal functioning.

1. OVERVIEW OF SOLAR CHECK VALVES

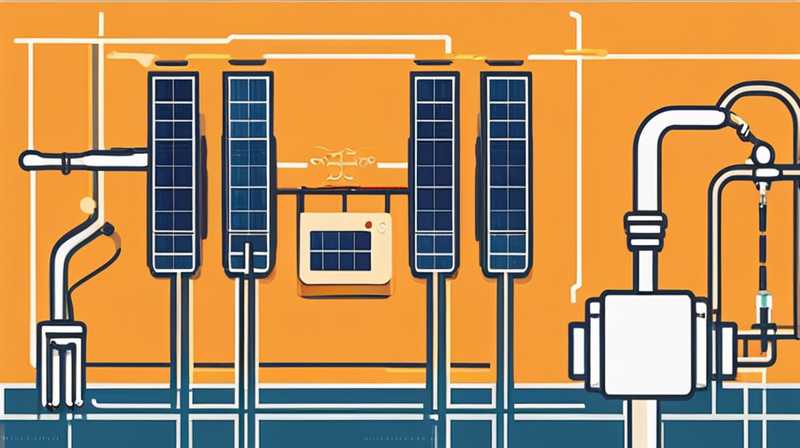

Solar check valves play a crucial role in the context of solar energy systems, specifically those that involve circulating fluids such as water in solar heating applications. These devices are essential for maintaining the integrity of the system by preventing backflow, which can disrupt the flow of heated water from the solar collector to the storage tank. In essence, a solar check valve ensures that the system operates efficiently without any thermal loss.

Each solar check valve consists of a valve body, a spring mechanism, and a diaphragm or ball that helps to control the flow of fluid. When water is heated in the solar collectors, it expands and moves towards the storage tank. The check valve opens to allow the flow in one direction, while the spring mechanism ensures that it closes tightly when there is no pressure, or in reverse flow situations. This functionality is imperative for the durability and efficiency of solar thermal systems.

The wiring aspect of these valves, which is critical for their operation, involves understanding the electric components that control the valve mechanism. These may include sensors that detect flow or temperature, and ultimately engage or disengage the valve accordingly. A meticulous approach to wiring ensures that the valve works in tandem with the entire solar heating system.

2. IMPORTANCE OF PROPER WIRING

The proper wiring of the solar check valve is not simply a technical requirement but a fundamental component of the overall system efficiency. When wires are connected correctly, the solar check valve operates in sync with the system, ensuring optimal performance. On the other hand, incorrect wiring can lead to various issues, such as water backing up into the solar collectors, inefficient heating, or even damage to the pump and other components.

Wiring affects the response time of the check valve to changes in pressure or temperature, which is crucial in a dynamic system like solar heating. A check valve that receives the right signals promptly will perform its function effectively. Therefore, understanding how to connect the wires appropriately cannot be overstated—it is essential for maintaining the reliability of solar energy systems.

Moreover, adhering to the manufacturer’s guidelines and local electrical codes is paramount when wiring the solar check valve. Not only does it ensure safety, but it also preserves the warranty of the product being used. Documentation provided by manufacturers often includes diagrams and specifications, offering invaluable insights into the intricacies of installation and repair.

3. TOOLS REQUIRED FOR WIRING

When preparing to connect the wires of a solar check valve, having the appropriate tools on hand is essential for a successful installation. Several tools can facilitate the wiring process; these tools enhance the speed and accuracy of connections, ultimately leading to a more reliable installation.

Wire Strippers are paramount for removing insulation from the wires without damaging them. Accurate stripping is necessary as excess damage can expose too much wire, posing a risk of short circuits. Different gauges of wire will require specific types of wire strippers.

Connectors are another essential component of the wiring process. Various connectors are available depending on the wire gauge and type being used. Crimp connectors are particularly useful because they create a secure bond between the wires without soldering. Ensuring that connectors are weatherproof can increase the longevity of the electrical connections in outdoor installations.

Insulation Tape is crucial for safeguarding electrical connections. Proper wrapping prevents moisture from infiltrating and causing corrosion or short circuits. Using high-quality insulation tape will enhance the durability of the connections and protect them from environmental elements.

In addition to these tools, electricians often utilize a multimeter to test for continuity and ensure that the electrical flow is working correctly before sealing connections. This added step can prevent future headaches associated with faulty wiring.

4. STEP-BY-STEP WIRING INSTRUCTIONS

Thoroughly understanding the wiring process can assist both amateurs and professionals alike in achieving optimal results when connecting the wires of a solar check valve. Here are clear steps to follow throughout the wiring process.

Preparation would be the first phase. Ensure that all tools and safety equipment are at hand. The workspace should be organized to avoid any unnecessary distractions. Before attempting any electrical work, always disconnect power to ensure safety. Familiarize yourself with the valve’s wiring diagram—this will serve as a roadmap for the entire procedure.

Next, identify the positive and negative wires. Most manufacturers will color-code these wires for ease. Typically, red signifies positive, while black is negative. Ensuring that these connections are accurately identified is pivotal; reversing them can result in malfunctions.

Stripping the Wires follows this identification stage. Employ your wire strippers to carefully remove insulation from each end of the wire. Exercise caution here to avoid cutting too deep and damaging the wire strands.

After stripping the wires, the next action is attaching connectors. Insert the stripped ends into the connector and use pliers or a crimping tool to secure them tightly. Ensuring a solid connection is vital; even a slight looseness can cause interruptions in the electrical flow.

Assemble all connections, and then it’s time to apply insulation. Wrap each connection thoroughly with electrical tape, ensuring no exposed wire is visible. Double-check for firmness and security of the connections.

Once the wiring is complete, testing it is essential. Use a multimeter to verify the continuity of the connections. Check that current flows as intended before reintroducing power to the system.

After successfully ensuring everything functions correctly, carefully organize the wires to prevent tangles or damage.

5. TROUBLESHOOTING COMMON ISSUES

Despite following all proper procedures, one might encounter issues that affect the performance of the solar check valve. Understanding potential pitfalls can make troubleshooting significantly more manageable.

One common problem is intermittent flow. If the valve occasionally opens and closes without command, this could be attributed to loose connections or corroded wires. Inspect the connectors for any signs of wear and resecure them as necessary. An unreliable connection can lead to erratic performance, affecting the overall system.

Another issue could be a complete failure to open or close. In such cases, it’s crucial to check the wiring diagram again and ensure that all connections are as per instructions. A multimeter can aid in confirming whether power is actually reaching the valve. If not, retrace steps to identify any overlooked errors in the wiring process.

Many of these problems can arise due to external factors, such as exposure to environmental conditions. Moisture can lead to corrosion, which is why adequate insulation and weatherproof materials are necessary. Regular inspections of the check valve and associated wiring should be a part of the routine maintenance of any solar energy system.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR CHECK VALVE?

A solar check valve is a crucial component in solar thermal systems, designed to prevent backwards flow of heated liquids from the storage tank back into the solar collectors. The valve ensures that the flow only occurs in one direction, which is vital for maintaining system efficiency and preventing potential damage. When the system is operational, the valve opens to allow heated fluid to reach the storage, and when the pump is inactive or when there is reverse pressure, it seals tightly to stop any backflow. Understanding how this mechanism functions is essential for anyone working with solar energy systems.

HOW DO I KNOW IF MY SOLAR CHECK VALVE IS WORKING PROPERLY?

Ensuring that a solar check valve is functioning properly involves several steps. The most important indicators of performance include ensuring there are no leaks, monitoring for unusual flow patterns, and using a multimeter to check for electrical continuity if it is electronically controlled. If you notice water backing up into the collectors, this could signify a malfunctioning valve. Performing routine maintenance and systematic inspections can help identify issues early on, ensuring that the check valve maintains its critical role in the solar energy system.

CAN I WIRE A SOLAR CHECK VALVE MYSELF?

Yes, wiring a solar check valve can be performed by individuals with basic electrical skills and knowledge of solar thermal systems. However, diligence and adherence to safety protocols are entirely necessary. Ensure you reference the manufacturer’s wiring instructions and understand local electrical codes before proceeding. If you are uncertain about any part of the process, consulting with a professional is advisable. Safety should always take priority when working with electrical components, particularly in outdoor environments or where water exposure may pose additional risks.

In summary, connecting the wires of a solar check valve necessitates a methodical approach that incorporates safety, adherence to guidelines, and proper understanding of the device’s operation. The process involves preparation, identification of wires, careful stripping and securing, and comprehensive testing to guarantee effectiveness. This article outlines key aspects to consider: proper tools are essential for ensuring reliability, effective troubleshooting can mitigate common issues, and maintaining your system keeps it efficient. Ultimately, individuals planning to install these systems must understand that taking these systematic steps will lead to a successful solar energy experience. With solar energy gaining further traction globally, mastering such essential components contributes significantly to a sustainable future. Establishing thorough connections in solar thermal systems maximizes energy efficiency, minimizes maintenance costs, and enhances overall performance, which benefits homeowners and the environment at large. Thus, doing so is more than just ensuring the correct setup; it empowers a broader movement toward renewable energy usage.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-wires-of-the-solar-check-valve/