In the realm of solar self-priming pumps, connecting the wires entails several steps that are critical to ensuring operational efficiency. 1. Understand the wiring diagram provided by the manufacturer, 2. Verify the compatibility of components, 3. Ensure safety measures before commencing work, 4. Utilize proper tools to execute connections. A thorough comprehension of the wiring diagram is paramount, as it illustrates how each component interrelates and functions in tandem. Additionally, it’s vital to ascertain that all components, including the pump, solar panels, and battery (if applicable), are compatible to prevent any electrical mismatches. Finally, prioritizing safety ensures that the setup is not only functional but also secure for long-term usage.

1. UNDERSTANDING SOLAR SELF-PRIMING PUMPS

Solar self-priming pumps represent a remarkable innovation in the realm of sustainable energy solutions. These pumps harness the immense power of sunlight to facilitate water movement efficiently, especially in remote areas where electricity may be intermittent or unavailable. One of the critical factors contributing to their effectiveness is the wiring system that connects the solar panels to the pump. A profound understanding of this wiring setup is essential for optimal performance.

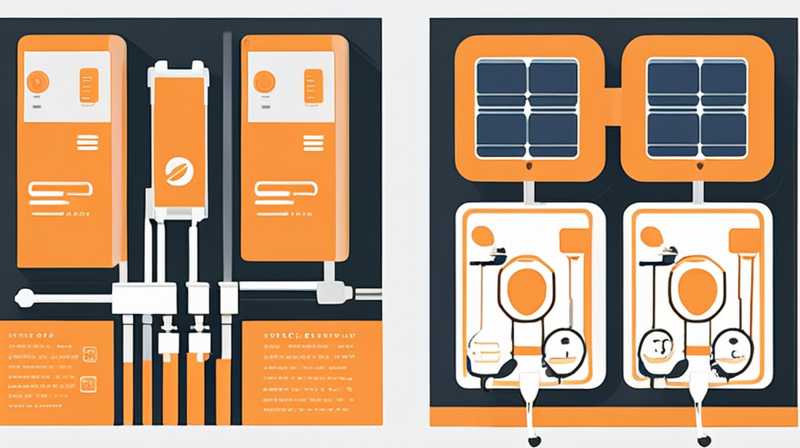

The main components involved typically include the solar panel, the pump itself, and a control device such as a solar regulator. When installing this system, gaining insight into how electricity flows from the solar panel into the pump provides a clearer picture of overall functionality. Without the requisite knowledge of the components’ interplay, one may encounter challenges during installation or operation, leading to inefficient water delivery or complete system failure.

ROLL OF WIRING DIAGRAM

Consulting the wiring diagram frequently provided by the manufacturer is vital when connecting the wires. This diagram delineates the exact configuration needed for optimal performance. Each wire in the setup has a specific role and must connect to the correct terminal or component for effective operation. It is important to follow the diagram meticulously to avoid potential mistakes that may cause short circuits or inefficiencies in water flow.

Additionally, pay attention to the wire color coding, which is often standardized within the industry. For instance, positive and negative wires are typically represented by different colors, facilitating easier identification during the installation process. This systematic approach helps to ensure that the electrical flow mirrors the design specifications, laying the groundwork for a successful setup.

2. COMPONENT COMPATIBILITY

Compatibility among components serves as a cornerstone for any effective solar pump installation. This involves ensuring that the pump is suited for the voltage output of the solar panels, as well as the battery’s capacity, if one is used in the system. Neglecting this aspect can lead to operational challenges, such as an insufficient power supply for the pump or, conversely, the risk of damaging electrical components.

Moreover, the specifications of the solar panels must align with the energy demands of the pump. For instance, if a pump requires a certain wattage but the solar panel outputs less, the pump may either underperform or fail altogether. It’s prudent to review product documentation carefully and gauge the compatibility of various components before starting the wiring process. Such diligence can save both time and resources in the long term.

PRE-INSTALLATION CHECKS

Performing thorough pre-installation checks is indispensable in guaranteeing successful connections. Ensuring that each component is functional is essential; this may include testing the solar panels for output efficiency and examining the pump for operational integrity. During this step, one should also verify that all safety measures, such as circuit breakers and fuses, are in place to protect against electrical surges.

Furthermore, assessment of physical connections between components, along with an examination of connectors and terminals, is critical. Loose connections can result in erratic performance and increased wear on components. Thus, it is wise to physically inspect and confirm that all connections are secure before proceeding with wiring.

3. SAFETY MEASURES

Safety protocols form an integral part of ensuring a trouble-free installation process. Engaging with electrical systems inherently involves risks, particularly when generating and using energy. Prior to commencing work on solar self-priming pump connections, it is crucial to disconnect any power sources and utilize personal protective equipment (PPE) such as gloves, goggles, and non-conductive footwear. This basic precaution guards against electrical shocks that could have dire consequences.

Engaging in proper grounding techniques cannot be overstated. Connecting the solar panel system to an appropriate grounding mechanism allows electrical surges to be redirected safely, minimizing the risk of damage to components. Adhering to local electrical codes and standards is also a must; different jurisdictions may have specific regulations that must be observed during installation.

HANDLING TOOLS PROPERLY

Using appropriate tools is just as crucial in assuring a safe working environment. Tools like wire strippers, crimpers, and multimeters must not only be suitable for the task at hand but also in good working condition. For instance, worn-out wire strippers can lead to poor connections, which may cause performance issues later on. Additionally, reading the instructions for each tool ensures that they are used correctly, maximizing both effectiveness and safety.

Ensuring that workspaces are organized helps prevent hazards associated with clutter or misplaced tools. A clean workspace minimizes risks and enables a better focus on the task. Further, it’s beneficial to double-check the condition of tools before beginning the wiring process to ensure they are fully functional and safe to use.

4. EXECUTING CONNECTIONS

Once the groundwork has been established, execution of the actual connections can begin. Referencing the previously mentioned wiring diagram continues to be of paramount importance during this phase. Each connection should be treated with care, as one incorrect connection can lead to severe problems down the line.

Carefully strip the insulation from wire ends, allowing appropriate length for securely attaching to terminals. Utilizing connectors that are compatible with the wires and terminals ensures a stable electrical connection. It is advisable to use heat-shrink tubing or electrical tape to provide additional insulation and waterproofing for the connections. Ensuring a solid electrical connection effectively mitigates the risk of overheating or short circuits.

TESTING FOR FUNCTIONALITY

After connections are made, testing the system’s functionality becomes critical. Reconnecting the power source cautiously allows for initial assessments of performance. Observing how the solar panels engage with the pump will provide insights into whether the setup has been effective. One should also monitor the pump’s performance during initial operation to gauge efficiency and identify any anomalies.

If any issues arise during testing, revisiting each connection is imperative. Sometimes, simple adjustments can significantly alter performance outcomes, ensuring that the pump operates as intended. Early detection of problems during testing significantly reduces the chances of encountering operational failures later.

5. MAINTAINING YOUR SYSTEM

The journey does not end once the setup has been installed and tested successfully. Effective maintenance routines serve to prolong the life expectancy and performance of the solar self-priming pump system. Regular inspections should be conducted to assess the condition of wiring and connections, ensuring they remain intact and free from wear or corrosion.

MONITORING PERFORMANCE OUTPUT

Monitoring the energy output from solar panels is also an invaluable aspect of maintenance. Variations in output may signify issues necessitating adjustments or repairs. Keeping detailed logs can help identify patterns in performance, providing a focal point for assessing operational health over time.

In addition, seasonal preparation is a proactive way of ensuring continued efficiency. For instance, in areas prone to extreme weather, extra precautions may be necessary to safeguard the pump and wiring, thereby protecting the system from potential damage.

6. TROUBLESHOOTING COMMON PROBLEMS

Even with proper installation and maintenance, problems may occasionally arise. Recognizing and troubleshooting common issues can prevent further complications. For example, if the pump isn’t operating correctly, issues may revolve around insufficient power from the solar panels, a blocked impeller, or a faulty connection within the wiring.

CHECKING SOLAR INPUTS

Confirming inputs from the solar panels is vital if the pump fails to start. This includes verifying that the panels have unobstructed sunlight and clean surfaces to optimize energy capture. If the solar input seems adequate but the pump remains nonfunctional, checking the integrity of the wiring becomes essential.

In cases where the system doesn’t perform to expectations, it may be necessary to consult manufacturer guides or seek professional assistance to address more complex issues. Early intervention can save both time and expenses in the long run.

COMMONLY ASKED QUESTIONS

HOW DO I CHOOSE THE RIGHT SOLAR SELF-PRIMING PUMP?

Selecting the appropriate solar self-priming pump begins with assessing specific requirements. Considerations include intended use, power source capability, and flow rate needs. Research various models in conjunction with reading user reviews can guide in making informed decisions. Consulting with vendors, who can provide guidance based on their expertise, ensures that chosen options align with expectations.

WHAT MAINTENANCE IS REQUIRED FOR A SOLAR PUMP SYSTEM?

A routine inspection is fundamental for a solar pump system’s longevity. Monitor wire connections for wear, check the integrity of components like batteries and regulators, and clean solar panels regularly to maximize energy efficiency. Creating a maintenance schedule allows for consistent checks without overlooking critical aspects. These strategies promote prolonged functionality and operational reliability.

CAN SOLAR SELF-PRIMING PUMPS WORK IN LOW SUNLIGHT CONDITIONS?

Indeed, solar self-priming pumps can still function in low sunlight conditions; however, performance may be impacted. These pumps often require copious amounts of solar energy for effective operation. If consistent low light is an issue, supplemental power sources, such as batteries, can store energy for use during insufficient sunlight intervals. Understanding the geographic area helps in forecasting energy requirements.

To summarize, connecting the wires of a solar self-priming pump requires a deep understanding of components, compatibility checks, robust safety measures, and methodical connection execution. Emphasizing crucial aspects ensures operational efficiency over time. Regular maintenance and troubleshooting further extend the life of the system. Accurate knowledge enables effective installation, while a proactive approach ensures continued performance. This integration of skills and knowledge empowers users to optimize their solar pump systems, transforming sustainable practices into flawless functionality. Each element contributes to a functioning entity that harnesses solar energy effectively, ultimately creating an efficient cycle of usage and maintenance that is pivotal in realizing the benefits of renewable energy in daily applications.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-wires-of-solar-self-priming-pump/