To successfully connect the wires of a solar electronic valve, one should follow an organized approach that ensures both safety and functional efficiency. 1. Proper identification of components, 2. Using suitable tools, 3. Understanding wiring configurations, 4. Safety precautions are crucial aspects to consider during this process. The integration of solar technology with electronic valves requires careful connectivity due to the intricate designs of both systems.

In this article, the focus will be on presenting a comprehensive guide to establish connections effectively. The detailed steps outlined below will empower individuals to connect solar electronic valves confidently.

1. COMPONENT IDENTIFICATION

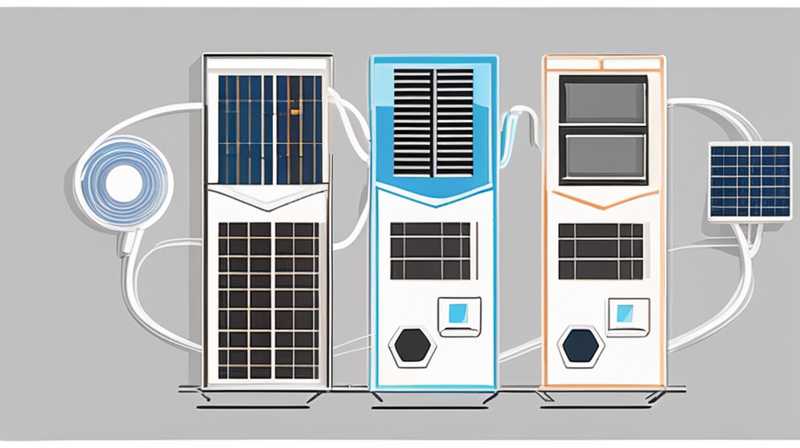

Before embarking on the wiring procedure, it is essential to identify all the components involved. Understanding the specific parts of both the solar panel system and the electronic valve is paramount. A solar electronic valve typically includes components such as solenoids, control wires, and power sources. Recognizing each part’s functionality allows for a clearer assembly approach.

Additionally, solar panels come with their own wiring systems, including positive and negative leads. Making sure to correctly identify these wires ensures that the current flows as intended. Refer to manufacturer’s diagrams and manuals to familiarize oneself with the wiring setup specific to the devices being installed. This prevents mistakes that could lead to malfunction or damage.

2. TOOLS REQUIRED

The procedure necessitates an array of tools effective for wiring tasks. Commonly used equipment includes wire strippers, connectors, and insulated pliers. Each tool serves a purpose in ensuring that connections are secure and appropriately insulated. The wire strippers will allow for the precision required to expose wire ends without damaging them.

Moreover, connectors, whether they are butt connectors or terminal connectors, facilitate reliable electrical continuity between wires. Using these tools effectively will enhance the safety and functionality of the entire installation. It is vital to have quality tools on hand, as poor-quality equipment can lead to poor connections and increased risk of failure.

3. WIRING CONFIGURATIONS

Understanding various wiring configurations is pivotal for seamless operation. Different solar electronic valve systems may have unique wiring needs according to types and manufacturers. Familiarity with series and parallel connections is essential as it determines how the components interact with each other and the power supply.

For instance, in a series connection, power flows through each component one by one, while a parallel configuration allows each component to receive power independently. Recognizing these configurations enables one to choose the appropriate layout based on the application requirements. This understanding will prevent potential operational issues and ensure the system works efficiently once installed.

4. SAFETY PRECAUTIONS

Safety is paramount when dealing with electrical components. It is crucial to disconnect power sources before commencing any wiring work to prevent electrical shock. Wearing insulated gloves and using tools with insulated handles minimizes the risks involved in connecting electrical components.

Furthermore, carefully inspecting wires for damage, fraying, or any signs of wear is also advisable. This preemptive measure prevents failures that may arise from weakened components. Establishing a safe working environment will not only safeguard the individual performing the task but also ensure that the system itself remains functional without risk of electrical hazard.

5. CONNECTING THE WIRES

With the components and tools ready and a clear understanding of the configurations and safety guidelines, one can proceed to connect the wires of the solar electronic valve. Start by stripping approximately half an inch of insulation from each wire end you plan to connect. This should be done carefully to avoid cutting through the wire itself.

After stripping the wires, it’s time to connect them using the appropriate connectors. Ensure that the exposed wire ends are inserted properly into the connectors. A secure fit is essential, as loose connections can lead to energy loss and potential system failure.

Furthermore, you’ll want to follow the specific wiring diagram provided by the valve’s manufacturer. Correctly matching the positive and negative terminals with those of the solar panel is absolutely necessary. This synchronization ensures that the voltage flows correctly through the system, thereby allowing for efficient operation.

6. TESTING THE CONNECTION

Once everything is connected, the next step involves testing the system to confirm it functions properly. Reconnecting the power source allows for initial testing; however, caution should be exercised when reapplying power. Carefully observe for any irregularities, such as unexpected sounds or smoking, as these may indicate improper connections.

After powering on the system, monitor the valve’s performance to ensure it operates according to the set specifications. If any issues arise, it may be necessary to troubleshoot by checking each connection for accuracy and integrity. This step is vital to ensure long-term and reliable operation of the solar electronic valve system.

7. MAINTAINING THE SYSTEM

Regular maintenance plays a key role in maximizing the life and functionality of a solar electronic valve system. Routine checks should include inspecting connections for signs of wear or corrosion. This preventative action can help identify and resolve issues before they grow into more significant problems.

Moreover, keeping the solar panel clean and unobstructed can ensure optimal energy capture, thus supporting overall system performance. Establishing a scheduled maintenance routine will allow users to proactively address any potential issues. This approach significantly contributes to the sustainability and reliability of the solar energy system.

FAQs

WHAT IS A SOLAR ELECTRONIC VALVE?

A solar electronic valve is a device used to control the flow of fluids by responding to signals from a solar panel system. These valves typically utilize solenoids, which are electromagnetically operated, to open or close fluid pathways. The integration of solar power allows for operations without needing direct electrical connections to a conventional power grid, which is ideal for remote or off-grid applications. This independence enhances versatility and reduces costs associated with electrical supply. Solar electronic valves typically find applications in irrigation systems, where automated fluid control leads to efficient resource management. Understanding their operation contributes to the effective implementation of sustainable water management solutions.

HOW LONG DOES INSTALLATION TAKE?

The duration of installation for a solar electronic valve can vary significantly based on the individual’s experience, the complexity of the system, and the specific requirements of the project. For someone with a solid understanding of electrical wiring and familiarity with the components involved, the entire process may take approximately two to three hours. However, for those less experienced, it may extend to a full day. Factors influencing installation time include the difficulty of routing wires, securing connections, and any needed debugging. Each of these requirements can add complexity, making it essential for installers to take their time ensuring accuracy for long-term system reliability.

CAN I INSTALL A SOLAR ELECTRONIC VALVE MYSELF?

Yes, one can install a solar electronic valve independently, provided that they possess the requisite skills and understanding of electrical systems. It is essential to approach the installation with caution and thorough knowledge of the wiring process to avoid any hazards. Familiarity with electrical principles, safety measures, and the specific components involved in the installation process is critical. For those lacking experience, it may be prudent to consult with a professional or at least follow detailed instructional materials to guide the assembly. Doing so minimizes the risk associated with electrical work and enhances the overall success of the installation endeavor.

FINAL THOUGHTS

The connection of wires to a solar electronic valve is a multifaceted process that requires careful attention to detail and adherence to safety protocols. Mastering the components, utilizing the right tools, understanding wiring configurations, and prioritizing safety measures all contribute to a successful installation. A precise connection enhances the overall efficiency of the solar system, enabling optimal fluid control while leveraging renewable energy sources responsibly.

Engaging in routine maintenance and employing best practices plays a pivotal role in ensuring the longevity and reliability of the installation. Regular inspections, combined with a commitment to addressing issues proactively, guarantee sustained performance over time.

Ultimately, empowering oneself with knowledge about the workings of solar electronic valves not only promotes energy efficiency and sustainable practices but also fosters a growing awareness of renewable technologies. As the world pivots towards greener energy options, developing such skills becomes increasingly vital for individuals keen on contributing to environmental conservation. Through informed decision-making and responsible installation practices, one becomes part of a broader movement towards a more sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-wires-of-solar-electronic-valve/