1. To connect the valve to the two solar pipes, follow these steps: identify the correct type of valve for your solar system, ensure all necessary tools and materials are gathered, properly prepare the pipes by cutting them to the appropriate length, install the valve in the correct position, secure all connections using appropriate fittings, and finally, check for any leaks or issues after installation. Each step requires careful attention to detail to ensure functionality and efficiency.

1. UNDERSTANDING SOLAR PIPE SYSTEMS

The integration of solar energy systems into residential or commercial settings has gained momentum in recent years. Central to these systems are solar pipes, which serve the essential purpose of transporting heated fluid from solar collectors to storage tanks or heat exchangers. Understanding the fundamental aspects of solar pipe systems is crucial for effective installation, maintenance, and functionality.

When working with solar pipes, it is vital to recognize the importance of choosing high-quality materials, as these pipes are subjected to varying temperatures and pressures. Issues such as corrosion or degradation can diminish their efficiency over time. Among the different types of materials used for solar pipes, copper and polyethylene are the most common. Copper is often preferred for its durability and thermal conductivity, while polyethylene is chosen for its flexibility and resistance to UV radiation.

Additionally, every solar heating system typically consists of two primary circuits: one for collecting solar energy and another for transferring that energy. Understanding the distinction between these two circuits is integral to the installation and connection of valves, ensuring proper flow regulation and pressure management.

2. SELECTING THE APPROPRIATE VALVE

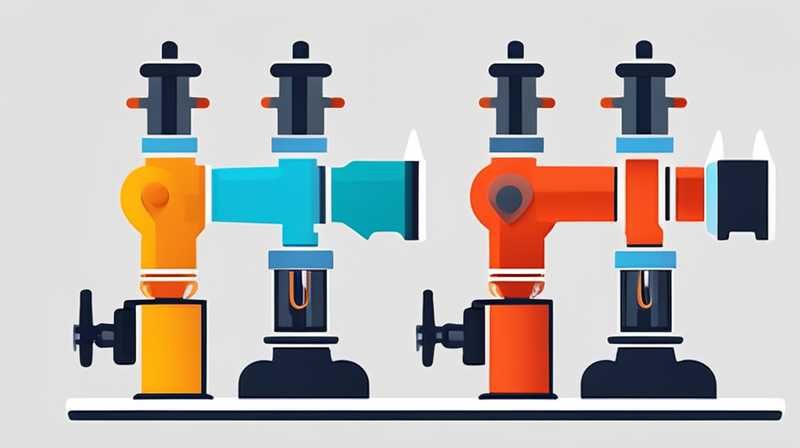

Choosing the right valve is paramount for effective operation in any solar heating system. Variety in valve types exists, each designed for specific functions and applications. The choice of valve can impact the efficiency and performance of the system, making it crucial to consider factors such as the fluid type, system pressure, and temperature ranges.

A ball valve is one option that is widely used in solar thermal applications due to its reliable sealing capability and low pressure drop. This valve operates with a spherical disc that controls flow, making it highly effective for turning the flow on and off. On the other hand, check valves play an essential role in preventing backflow, ensuring that heated fluid does not return to the collector circuit.

It is also important to consider the installation requirements for the selected valve. Some valves may require specific orientations during installation, while others can be fitted in a variety of positions. The physical dimensions of the valve, including its size and thread specifications, must match those of the solar pipes.

3. PREPARING THE SOLAR PIPES

Preparation of the solar pipes is a critical phase prior to the installation of the valve. This involves several key steps, including measuring and cutting the pipes to the appropriate lengths and ensuring that all surfaces are smooth and free from debris. The integrity of the pipes is pivotal in allowing for secure and leak-free connections.

Before cutting or joining the pipes, measuring the required lengths accurately is necessary to avoid any excess material. Employing appropriate cutting tools, such as a pipe cutter or hacksaw, will yield clean edges that are crucial for sealing. An essential aspect of preparation is deburring the cut edges with a file or pipe reamer, allowing for better fitting and preventing damage to fittings during insertion.

Furthermore, it is advisable to clean the pipe ends with a suitable solvent. This ensures that any dirt, oil, or other contaminants do not interfere with the bonding process during installation. Attention to detail during preparation not only simplifies the installation process but also enhances the longevity of the installations.

4. INSTALLING THE VALVE

The installation of the valve requires precision and adherence to best practices. Begin by determining the appropriate location for the valve—ideally, it should be installed in a position that facilitates easy access for maintenance and operation. Positioning the valve too far from the solar pipes may yield challenges in terms of monitoring and adjustment.

Once the location is established, it is imperative to ensure that all connections are tightly secured. Utilizing the right type of fittings is essential in this process. Whether using threaded fittings or slip fittings, confirm compatibility with both the valve and the existing solar pipes. During the installation, it is critical to employ Teflon tape or suitable joint compound on threaded connections to prevent leaks.

Additionally, exercise caution while tightening connections—over-tightening can lead to damage to the pipes or fittings. After installation, inspection for leaks is of utmost importance. Running the system at low pressure for a period of time will reveal any issues that need addressing, ensuring that the installation is sound and reliable.

5. MONITORING AND MAINTAINING CONNECTIONS

Post-installation monitoring and maintenance are vital components for ensuring sustained system efficiency. Regular inspections will help identify signs of wear, corrosion, or leaks within the system. Observing pressure gauges and maintaining proper fluid levels will also assist in detecting potential failures before they escalate into significant issues.

Implementing a routine maintenance schedule is advisable. This could include activities such as checking the functionality of the valves, assessing the state of pipe insulation, and cleaning any components that may traps debris. Over time, sedimentation may build up within the pipes, which can obstruct flow and efficiency. Regular cleaning can help mitigate this risk.

Through consistent monitoring and maintenance routines, the overall lifespan of the solar system can be extended. Addressing minor issues as they arise will ensure the system operates at peak efficiency, providing reliable and sustainable energy for its designated purpose.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF VALVES ARE BEST FOR SOLAR PIPE CONNECTIONS?

Selecting the most suitable valve involves consideration of various factors, including flow requirements and system pressure. Ball valves are often the preferred choice for their simplicity and effectiveness at controlling flow. Their design minimizes pressure loss, making them ideal for solar thermal applications. Similarly, check valves are crucial in preventing reverse flow, protecting the system from potential backflow and associated issues. Additionally, solenoid valves could be used for automated control in more complex systems. Ultimately, the choice of valve should align with system requirements and operational conditions.

HOW DO I PREVENT LEAKS AFTER INSTALLING THE VALVE?

Preventing leaks post-installation hinges on meticulous attention to detail during the installation process. It is imperative to ensure that all connections are appropriately tightened but not excessively, as over-tightening can cause damage. The usage of Teflon tape or joint compound seals threaded connections effectively. Furthermore, it is critical to monitor the system after installation for any signs of leakage. Conducting a low-pressure test, observing joints, and inspecting fittings can help identify potential leaks early on, providing an opportunity for timely repairs before major issues arise.

HOW OFTEN SHOULD I MAINTAIN MY SOLAR PIPE SYSTEM?

The frequency of maintenance on a solar pipe system directly influences its efficiency and longevity. Regular inspections should ideally occur on a seasonal basis, aligning with system usage patterns. During these routine checks, components such as valves, fittings, and pipes should be assessed for integrity, wear, or signs of leakage. Any buildup of sediment within the pipes should also be monitored, as this can hinder system performance. Additionally, monitoring fluid levels, checking insulation condition, and verifying pressure gauges are all critical aspects of a comprehensive maintenance routine. Establishing a consistent schedule will significantly improve the reliability and effectiveness of the solar system.

In summation, meticulously connecting a valve to two solar pipes entails several intricate steps that require careful consideration and execution. Initial steps consist of selecting the appropriate valve based on system specifications, understanding the dynamics of solar pipe systems, and preparing the solar pipes for connecting. Particular emphasis should be placed on correct alignment and securing of joints to prevent potential leaks. Following installation, vigilant monitoring and maintenance become crucial in sustaining system efficiency and longevity. Adopting structured maintenance routines and frequent inspections will ultimately ensure optimal performance and durability of the solar piping system, making it a valuable asset to any energy-efficient endeavor. Ensuring attentiveness at every stage matters significantly, alongside the accurate selection of components. The need for operational integrity reinforces the importance of following industry best practices and leveraging appropriate materials to optimize the functionality of a solar heating system.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-valve-to-the-two-solar-pipes/