To connect a solar two-way valve without leakage, one must ensure proper alignment, select the appropriate fittings, and employ precise techniques during installation. This process involves several crucial steps, including 1. Choosing quality components: Quality valves and fittings are essential to prevent leaks. 2. Careful alignment: Ensuring all parts are properly aligned minimizes the chance of gaps that could lead to leaks. 3. Appropriate sealing methods: Utilizing the right sealing methods, such as thread sealant or PTFE tape, is critical in creating a watertight bond. 4. Testing connections: Conducting a pressure test after installation can identify potential leaks before the system is put into operation. Each of these factors plays an important role in ensuring a successful and leak-free connection.

1. UNDERSTANDING SOLAR TWO-WAY VALVES

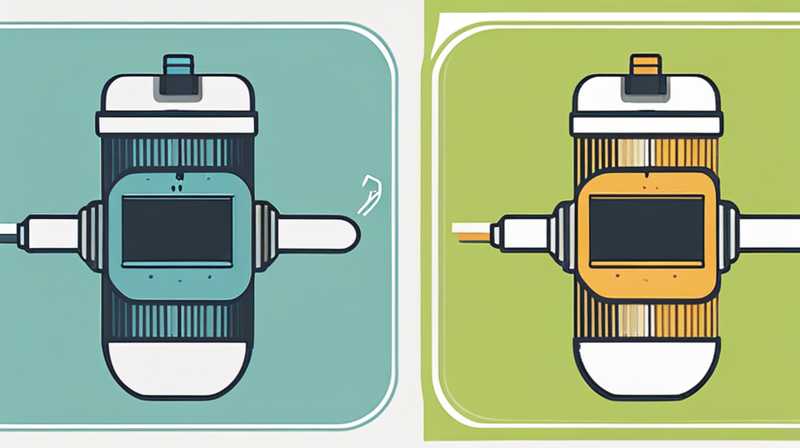

In solar thermal systems, the two-way valve serves a crucial purpose by regulating the flow of heat transfer fluid, ensuring efficient heat capture and circulation. Typically found in both residential and commercial solar applications, this valve’s design allows for switching the fluid’s direction, optimizing system performance. For effective operation, it is essential to grasp the mechanics and features of these devices, including how they function to manage the flow of water or another heat transfer medium.

The construction of a solar two-way valve often involves materials resistant to corrosion and thermal expansion, thereby ensuring longevity and functionality. Commonly made of brass or durable plastic, each material presents distinct advantages. Brass is known for its robustness, while plastic offers lightweight and resistance to certain chemicals. Understanding these characteristics provides insight into selecting the right valve based on specific application needs, which contributes to minimizing potential risks like leaks during installation.

2. PREPARATION PRIOR TO INSTALLATION

Proper preparation plays a pivotal role in achieving a leak-free connection. Before embarking on the installation, several preparatory steps must be meticulously executed. First, assess the installation area to ensure it is clean and free of debris. Dust and other particles can interfere with connections, potentially leading to leaks. Additionally, ensure that all tools and materials are on hand before beginning the process, which promotes a smoother workflow.

Next, carefully examine the fittings and valves for any visible defects or signs of damage. A thorough inspection is critical, as any imperfections can hinder the sealing process leading to leaks. Utilizing a quality sealant is essential, as it acts as a barrier between components, preventing fluid from escaping the system. Selecting the correct type of sealant that matches the materials involved in the installation can enhance the effectiveness of the connection and ensure a watertight seal.

3. INSTALLATION TECHNIQUES

Implementing effective installation techniques is vital when connecting a solar two-way valve. The initial step involves positioning the valve correctly. Ensuring that the valve is oriented according to the manufacturer’s specifications is critical, as any misalignment may compromise functionality and create a potential leakage point. Additionally, utilizing a level can ensure proper horizontal or vertical orientation, contributing to reduced stress on the valve materials during operation.

Once the valve is positioned correctly, it is crucial to tighten connections uniformly. Overtightening can often lead to damage, while insufficient tightening may allow gaps for leaks. Employing a torque wrench can assist in achieving the necessary tightness without excess force. Applying thread sealant or PTFE tape on threaded fittings before assembly will help create a tighter bond, further reducing the risk of leaks. During this phase, patience and precision are paramount.

4. TESTING FOR LEAKS

After installation is complete, conducting a thorough testing phase is essential. Testing for leaks should be done methodically and can often determine the reliability of the installation. Begin by gradually increasing the pressure in the system, observing each connection carefully for any signs of leakage. Bubbles forming at joints indicate the presence of leaks, necessitating repairs before the system becomes operational.

In addition to visual inspections, consider using a pressure gauge to monitor the system’s overall integrity. Maintaining pressure within acceptable limits is crucial; deviations may suggest leaks or other issues that require immediate attention. If leaks are detected, it’s important to diagnose the root cause and address any negligence in the installation process, reinforcing connections or replacing components as necessary.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF MATERIALS ARE BEST FOR SOLAR TWO-WAY VALVES?

When selecting materials for solar two-way valves, one should consider both durability and corrosion resistance. Common options include brass and various types of plastics. Brass is highly favored for its strength and longevity, while plastics such as PVC or CPVC can provide significant resistance to chemicals and environmental factors. Additionally, working with rubber O-rings and other sealing materials can enhance the connection’s effectiveness, reducing corrosion-related issues and prolonging overall system life.

The choice of material plays a significant role in applications exposed to heat and fluctuating temperatures. Brass, for instance, withstands thermal expansion better than many plastics, making it suitable for solar thermal systems. In contrast, lightweight plastic options may simplify installation but can be prone to failure under high-stress conditions. Ultimately, selecting the right material depends on the specific requirements of the installation context while aligning with industry standards for maximum efficiency and minimal leakage risk.

HOW OFTEN SHOULD SOLAR TWO-WAY VALVES BE REPLACED?

The lifespan of solar two-way valves is contingent upon various factors, including material quality, operational conditions, and maintenance practices. Generally, high-quality valves can last anywhere from 10 to 20 years when subjected to proper care and routine maintenance. Regular inspections to check for signs of wear, corrosion, or mechanical failure are crucial.

If the system experiences significant temperature fluctuations or has been exposed to harsh environmental conditions, an evaluation of the valve should occur more frequently. It’s advisable to maintain a close monitoring routine, especially after major weather events or shifts in system pressure. Ultimately, replacing the valves when wear is observed can prevent more severe issues, including leaks that jeopardize both system efficiency and safety.

HOW CAN I DETECT LEAKS IN MY SOLAR SYSTEM?

Detecting leaks in a solar thermal system involves a combination of observation and testing. Start with a visual inspection to look for signs of moisture accumulation or corrosion near the valves and connections. Small leaks may present as corrosion or wet spots, allowing for quick identification. Beyond visuals, utilizing soap solution tests can help uncover leaks more effectively; applying the solution to connections can create bubbles at leak sites.

Moreover, implementing pressure testing is a highly effective method for leak detection. By monitoring system pressure over time using a pressure gauge, one can discern if there are any drops indicative of leaks. Additionally, infrared thermography can identify temperature variations in the system, pinpointing areas where leaks may be present. Addressing leaks immediately upon detection ensures prolonged system efficiency and prevents extensive damage or costly repairs.

To summarise, connecting a solar two-way valve without leakage entails a professional approach through meticulous preparation, effective installation techniques, and comprehensive testing. Selecting quality materials, ensuring proper alignment, and utilizing suitable sealing methods are vital components of a successful connection. The importance of routine maintenance and monitoring for potential leaks cannot be overstated; proactive measures will ensure the longevity and effectiveness of solar thermal systems overall. Addressing any issues early on can not only prevent small problems from escalating but also enhance system performance, thereby maximizing efficiency and sustainability. By paying attention to every detail and maintaining protective measures, one can enjoy the benefits of a robust and leak-free solar heating solution.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-two-way-valve-without-leakage/