To properly connect a solar tube to a valve, one must follow specific procedures to ensure a successful installation. 1. Understand the components involved, 2. Prepare the workspace adequately, 3. Follow the proper installation techniques, 4. Perform tests to ensure functionality. Connecting a solar tube involves several critical steps starting with the identification of the right materials, ensuring that all necessary tools are at hand, and carefully following the installation guidelines. Proper connection not only facilitates an efficient energy transfer but also impacts the overall performance of the solar system. One crucial aspect to highlight is the importance of securely sealing all connections to prevent leaks, which can compromise the system’s efficiency.

1. UNDERSTANDING THE COMPONENTS

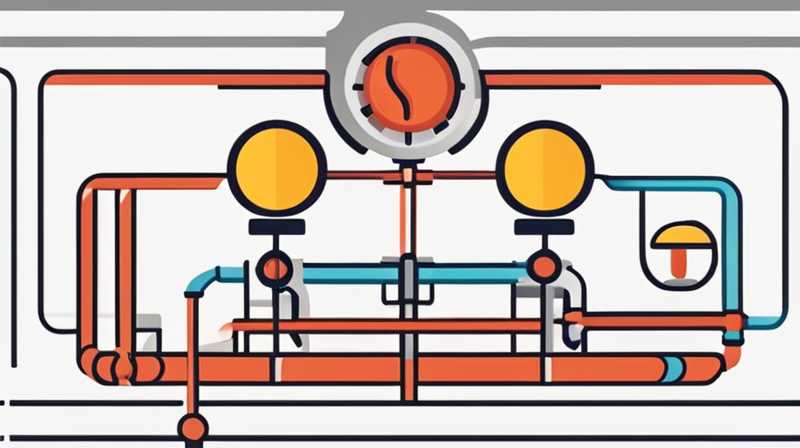

It is essential to grasp the various elements involved in connecting a solar tube to a valve. Solar tubes, also known as solar collectors, are designed to absorb sunlight and convert it into heat. They often play a vital role in solar heating systems. The valve, on the other hand, serves to regulate the fluid flow within these systems, ensuring that the heat generated is effectively transported to where it is needed. Familiarizing oneself with the specifications, types of both solar tubes and valves, and their compatibility is crucial before proceeding.

Having the appropriate components on hand enhances the likelihood of successful installation. Typically, appropriate solar tubes come with comprehensive installation kits, which include connectors, seals, and sometimes various tools needed for assembly. When selecting a valve, it’s important to choose one that complements the type of solar tube and the specific application. For instance, a three-way valve may be more suited for systems that require more complex control compared to a straightforward on-off valve. Thus, understanding both the solar tube and valve components ensures that they work harmoniously within the system.

2. PREPARING THE WORKSPACE

A well-organized workspace contributes significantly to the efficiency of connecting a solar tube to a valve. Start by identifying a clean, flat surface where tools and components can be laid out. Ensuring accessibility to power lines and plumbing connections is also helpful in facilitating the connection process. Prior to commencing, it is advisable to review the installation manual and gather all necessary tools, including wrenches, screwdrivers, sealants, and measuring tapes.

Safety measures should not be overlooked during workspace preparation. Proper protective gear—like gloves and goggles—should always be worn to safeguard against any potential hazards. Maintaining proper ventilation during the installation is also important, particularly if the processes involve any adhesives or sealants with potent fumes. Ensuring that there are no unnecessary distractions will allow for a focused approach toward the task at hand.

3. INSTALLATION TECHNIQUES

The installation process involves a series of meticulous steps to effectively connect the solar tube to the valve. Begin by positioning the solar tube in relation to the valve, ensuring a secure and stable fit. It is essential to align the inlet of the valve with the outlet of the solar tube. A crucial aspect of this connection is ensuring the correct orientation, which will affect the direction of fluid flow. After aligning the components, the next step is to attach them using the provided connectors.

Tightening the connections is equally important; under-tightened connections may result in leaks, while over-tightening can damage the components. A torque wrench is often very beneficial here, allowing for precision in achieving the required tightness without risk of damage. Once firmly attached, the next phase involves applying a sealant around the joint to reinforce the connection and provide additional watertight assurance.

4. TESTING FUNCTIONALITY

After completing the installation, conducting thorough tests becomes paramount to ascertain the system’s effectiveness and integrity. Begin by slowly filling the system with fluid while checking for leaks. Any visible leaks require immediate attention, prompting either tighter connections or additional sealant application. It’s often beneficial to conduct this test in stages, rather than rushing the process, which can lead to oversight.

Once the system is filled, activating the solar heating system is the next step. Observing how the valve operates in conjunction with the solar tube under different conditions enables one to assess efficiency effectively. Monitoring should not be limited to the immediate testing phase; periodic inspections afterward remain equally important to ensure ongoing operational efficacy.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS ARE NEEDED TO CONNECT A SOLAR TUBE TO A VALVE?

The tools required for connecting a solar tube to a valve typically include basic items such as wrenches, screwdrivers, sealants, Teflon tape, and measuring tapes. Depending on the specific design of your solar heating system, additional tools might be necessary. For example, a torque wrench may be very beneficial in ensuring that connections are tightened to appropriate specifications without causing damage. It is advisable to have an assortment of tools ready to avoid interruptions during the installation phase.

Another important tool might include a level for ensuring that the solar tube is mounted correctly. Proper alignment affects the efficiency of heat absorption, thus impacting the overall function of the system. Additionally, having a helper can facilitate the installation process, particularly when positioning heavy components. Following the installation manual closely is advised, as it can outline specific tools or methods tailored to the solar tube and valve set you are using.

HOW LONG DOES THE INSTALLATION PROCESS TAKE?

The duration of the installation process varies based on several factors, including the complexity of the system, individual experience, and availability of necessary tools. For a basic solar tube connected to a valve, the installation may take anywhere from a few hours to an entire day. First-timers may require more time, particularly if they are unfamiliar with the components or installation procedures.

Additionally, unforeseen issues such as missing parts or leaks can prolong the process. It is prudent to allocate extra time for troubleshooting and adjustments post-installation to ensure everything operates smoothly. Regular practice and experience with similar projects will ultimately shorten the time needed for future installations.

WHAT SHOULD BE CHECKED DURING TESTING?

During the testing phase, there are several crucial points to verify, including checking for leaks at all connection points, ensuring proper fluid flow through the valve, and monitoring the operation of the solar heating system. Closely observing these factors will provide insights into the integrity of the installation and the efficiency of operation.

It is also beneficial to monitor the temperature of fluid exiting the solar tube compared to that entering, as significant discrepancies may indicate issues. Listening for unusual sounds, such as hissing or gurgling, can also highlight potential air trapped in the system or unwanted restrictions in flow. Performing multiple test runs over time is useful for ensuring that the system maintains optimal functionality and that all components are working harmoniously.

FINAL THOUGHTS

Connecting a solar tube to a valve is not just a mechanical process; it requires attention to detail and an understanding of the overall system’s mechanics. Through mastering the components, preparing the workspace, implementing effective installation techniques, and performing thorough testing, one can achieve an efficient and effective connection. Each step must be executed with precision to prevent complications and to bolster the solar heating system’s performance.

An informed approach maximizes the benefits derived from solar technology and optimizes the installation process. Following the guidelines ensures that installations are done correctly, which is integral to maximizing energy conversion efficiency and system longevity. Continuous education and adherence to the manufacturer’s specifications significantly enhance the likelihood of achieving satisfactory outcomes, which is essential in promoting sustainable energy practices.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-tube-to-the-valve/