1. RECOGNIZING THE IMPORTANCE OF SOLAR THERMAL INSULATION PIPE JOINT CONNECTION

Connecting solar thermal insulation pipe joints requires attention to detail and adherence to specific protocols to ensure optimal efficiency and system longevity. This task typically involves the following key aspects: 1. Understanding the materials involved, 2. Utilizing the correct tools and techniques, 3. Implementing best practices for sealing and insulation, 4. Conducting routine inspections and maintenance to facilitate performance. Among these points, understanding the materials involved is critical, as using compatible materials not only enhances system performance but also minimizes possible leaks and wear that may arise from improper connection techniques.

1. UNDERSTANDING THE MATERIALS

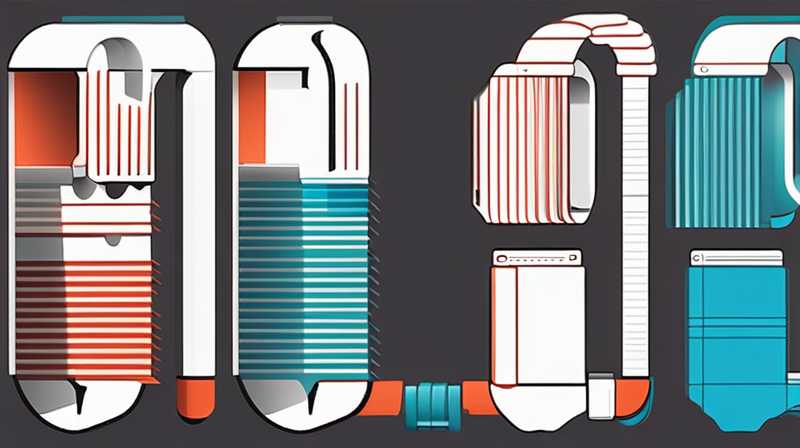

The connection of solar thermal insulation pipe joints heavily relies on the selection of appropriate materials. There are various types of pipes and insulation materials available, including polyethylene, copper, and polypropylene, each exhibiting unique characteristics that influence selection. Integrating the right materials ensures that the thermal energy transfer remains efficient and the entire system operates flawlessly.

Different insulation types, such as mineral wool or foam, must also be considered. For instance, foam insulation possesses excellent thermal resistance, which can significantly reduce heat loss. The compatibility of these materials with the pipes is paramount to prevent issues like degradation or structural failure. Failure to choose suitable materials can lead to increased thermal losses and excess maintenance costs, ultimately affecting the financial viability of a solar thermal system.

2. TOOLS AND TECHNIQUES REQUIRED

The process of connecting solar thermal insulation pipe joints necessitates specific tools and techniques. First and foremost, basic plumbing tools such as wrenches, cutters, and sealing tape are essential for creating solid, leak-free joints. Utilizing high-quality connectors designed for thermal insulation enhances the overall reliability of the joint. These components must be sourced from reputable suppliers to guarantee their performance.

In addition to proper tools, employing techniques like proper cutting and fitting is essential to achieving optimal joint integrity. Pipes must be cut to precise lengths using appropriate cutting tools to prevent rough edges, which could result in leaks or seal failures. Ensuring correct alignment during the assembly stage further aids in achieving a lasting connection, promoting the overall efficiency of the thermal system. Moreover, using thermal adhesive or sealant enhances the likelihood of maintaining temperature during operation.

3. SEALING AND INSULATION PRACTICES

The sealing and insulation of connected pipe joints play a pivotal role in the system’s performance. Achieving an airtight seal helps prevent heat loss and moisture ingress, which can compromise thermal efficiency. Utilizing high-quality sealants specifically designed for solar thermal applications will ensure durability and performance over time.

In addition to sealing, effective insulation needs to be installed around the joints to reduce thermal loss. Various insulation materials can be used, each with specific thermal resistance properties. When applied correctly, insulation minimizes heat exchange between the pipe and the ambient environment, thereby preserving energy efficiency. A thorough assessment of the insulation thickness and material type will help professionals determine the best approach for their specific installation.

4. MAINTENANCE AND INSPECTION

When it comes to solar thermal insulation systems, routine maintenance cannot be overlooked. Periodic inspections of the pipe joints can identify potential weaknesses or vulnerabilities before they escalate into significant issues. Routine maintenance involves checking for leaks, inspecting insulation integrity, and ensuring sealant effectiveness.

The timing of these inspections is crucial. Regular maintenance should occur ideally before peak usage seasons, ensuring that any repair work can be completed without disrupting service. Documentation of inspection findings is equally important, aiding in analysis over time and identifying trends or reoccurring issues within the system. Creating a detailed maintenance schedule can greatly enhance the longevity and reliability of solar thermal systems, ultimately maximizing investments in renewable energy strategies.

5. ENVIRONMENTAL CONSIDERATIONS

The environmental implications of connecting solar thermal insulation pipe joints cannot be disregarded. By selecting sustainable materials and employing efficient installation techniques, professionals contribute positively to reducing carbon footprints associated with traditional energy sources. Solar energy systems, when correctly installed and maintained, represent a significant step towards sustainable living practices.

Research indicates that the integration of renewable energy systems can lead to marked decreases in greenhouse gas emissions. Furthermore, as the demand for solar technology increases, so does the urgency in establishing effective practices for installation and connection of these systems. Thus, championing eco-friendly materials and sustainable methods not only supports environmental goals but also enriches community awareness regarding renewable energy importance.

6. COST EFFECTIVENESS

In addition to environmental factors, the cost implications associated with connecting solar thermal insulation pipe joints necessitate careful consideration. While initial investment in quality materials and skilled labor may seem steep, the long-term savings in energy bills and maintenance costs make this proposition financially viable. Research indicates that installations utilizing high-quality components significantly outperform their lower-cost counterparts in terms of durability and efficiency.

Moreover, the advancement of technology within the solar industry has led to innovations that reduce installation costs while improving system performance. By opting for emerging methods and technologies, consumers can capitalize on these advantages to optimize their investments. The balance between upfront costs and expected returns emphasizes the importance of implementing best practices in the installation of solar thermal systems.

SOLAR THERMAL INSULATION PIPE JOINT CONNECTION: FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON MATERIALS USED IN SOLAR THERMAL PIPE JOINTS?

Solar thermal pipe joints typically utilize materials such as polyethylene, copper, and polypropylene for the pipes and various insulation types including mineral wool and foam. Each material presents unique thermal properties, durability, and compatibility considerations. The appropriate selection hinges upon environmental factors, available resources, and desired system performance. Polyethylene, for example, is highly resistant to corrosion, while copper has excellent thermal conductivity. Properly assessing these choices directly impacts the system’s efficiency and overall effectiveness. Furthermore, insulation plays a crucial role in minimizing heat transfer losses. Thus, understanding these materials and their applications is vital for optimal joint connection.

HOW OFTEN SHOULD MAINTENANCE BE PERFORMED ON SOLAR THERMAL SYSTEMS?

Maintenance frequency for solar thermal systems demands a comprehensive approach. In general, inspections should occur at least once a year, preferably prior to the peak thermal usage season. During these inspections, particular attention should be paid to joint integrity, insulation conditions, and sealant effectiveness. Unscheduled maintenance might be necessary if irregularities or leaks are detected during routine checks. Regular upkeep not only extends system life but also ensures uninterrupted functionality. Documenting inspection results enhances trend analysis and guides future maintenance efforts. Maintaining a proactive inspection schedule fosters confidence in system reliability and performance.

WHAT TOOLS ARE NECESSARY FOR INSTALLING SOLAR THERMAL PIPE JOINTS?

Installing solar thermal pipe joints requires an assortment of specialized tools to ensure precision and quality. Essential tools include pipe cutters, adjustable wrenches, sealing tape, and thermal adhesive applicators. Additionally, a heat gun may be useful for softening certain insulation materials for easier application. Proper tools facilitate accurate cuts, creating clean edges that prevent leaks, and enable effective sealing. Employing unreliable or subpar tools can compromise the installation process, leading to potential future failures or inefficiencies. Therefore, investing in high-quality equipment and training for personnel is critical for successful joint connections.

**The process of connecting solar thermal insulation pipe joints represents more than merely uniting sections of piping; it encapsulates a multi-faceted approach requiring attention to detail, adherence to best practices, and an understanding of materials and techniques. Achieving a reliable, efficient connection begins with selecting the appropriate materials tailored to the desired operational efficiency. The use of high-quality materials significantly contributes to the longevity and effectiveness of the installation. Attention to the tools and techniques employed cannot be understated. Using proper plumbing tools and adopting meticulous techniques ensures that joints remain robust and leak-free.

Furthermore, the significance of effective sealing and insulation practices emerges as another critical component. Proper insulation techniques prevent thermal losses while also extending the life of the system. Conducting inspections and regular maintenance allows for the early identification of potential issues, ensuring sustained functionality over time. The environmental considerations tied to these systems highlight an overarching commitment to sustainability and carbon footprint reduction. These renewable energy systems are essential in advancing sustainable practices and conscious living approaches.

Cost-effectiveness is also a paramount consideration; although there may be an initial investment, the long-term energy savings present a compelling narrative for implementing these systems. In essence, connecting solar thermal insulation pipe joints forms a fundamental aspect of a wider initiative to harness renewable energy efficiently, achieving both ecological and financial goals. Ultimately, fostering educated choices leads to enhanced performance and satisfaction in energy production. The knowledge acquired can be disseminated across various platforms to promote the importance of solar thermal energy systems. By championing best practices, organizations and individuals alike contribute significantly to the transition towards a more sustainable future.**

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-thermal-insulation-pipe-joint/