To connect the solar thermal barrel joint, follow these steps: 1. Choose appropriate materials, 2. Ensure proper insulation, 3. Prepare joints adequately, 4. Utilize reliable fastening techniques. Each of these points is crucial for achieving a secure and effective connection in a solar thermal system. The selection of high-quality materials is essential because they guard against environmental factors and enhance system longevity. Proper insulation minimizes heat loss, which is vital in maintaining efficiency. Thorough preparation of the joints ensures a tight fit, while using dependable fastening methods guarantees durability under varying conditions.

1. UNDERSTANDING SOLAR THERMAL SYSTEMS

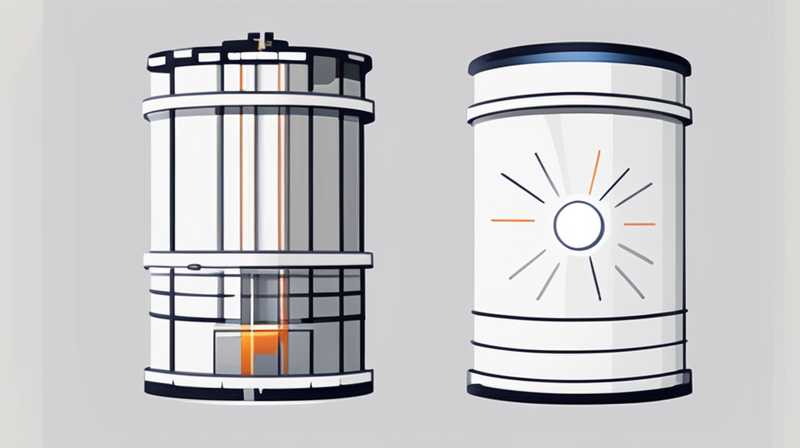

Solar thermal systems leverage sunlight to generate thermal energy, primarily used for heating purposes. They can heat water for domestic use or facilitate space heating, thus providing an eco-friendly alternative to conventional heating sources. The solar thermal barrel joint acts as a critical component in these systems, being instrumental in the connection of various elements, such as pipes and storage tanks, within the thermal network.

Solar thermal technology harnesses solar energy through collectors, which capture sunlight and convert it into heat. This heat is then transferred to a fluid, typically water or a glycol mixture, which circulates through the system, ultimately delivering energy to appliances or heating solutions. At the heart of ensuring efficiency in this setup is the linkage created by components, where the solar thermal barrel joint plays a pivotal role.

Utilizing these systems provides significant benefits, including reduced reliance on fossil fuels, lower utility bills, and a reduced carbon footprint. Understanding the mechanisms involved is vital for successful implementation, maintenance, and expansion of solar thermal systems. Furthermore, improving the connections between various components, including the barrel joints, enhances overall performance and extends equipment longevity.

2. MATERIAL SELECTION FOR CONNECTIONS

The selection of materials significantly influences the performance, durability, and efficiency of a solar thermal system. Opting for high-quality materials related to the solar thermal barrel joint is paramount, as they connect vital components ensuring effective heat transfer and minimal heat loss. Common materials used include copper, PEX, and stainless steel, each offering unique properties that cater to various needs.

Copper is often favored due to its excellent thermal conductivity and corrosion resistance. This metal facilitates effective heat transfer and durability, making it an ideal choice for connections within the thermal system. On the other hand, PEX (cross-linked polyethylene) has rapidly gained popularity in recent years. It is flexible, resistant to scale and chlorine, and simplifies installation due to its lightweight and ease of maneuverability. Utilizing PEX is beneficial particularly in tight spaces and in complex configurations, though special care must be taken regarding its sensitivity to ultraviolet light if exposed to sunlight.

Stainless steel presents another alternative, prized for its strength and resistance to corrosion. Although it may not conduct heat as well as copper, it is impervious to oxidation, making it suitable for external environments. When selecting the appropriate material, factors such as temperature extremes and exposure to environmental elements must be well considered. Each material plays a fundamental role in the stability and efficiency of the solar thermal setup, ultimately influencing operational performance.

3. INSULATION METHODS TO MINIMIZE HEAT LOSS

Effective insulation methods are critical for minimizing heat loss in solar thermal systems. As heated fluid passes through various connections, including those formed by solar thermal barrel joints, it’s imperative to maintain the temperature for optimal efficiency. Several insulation techniques can be employed to achieve this, each presenting unique advantages.

One widespread approach involves the use of foam insulation, commonly made from materials like polyurethane. This option is favored due to its high degree of thermal resistance, making it exceptionally proficient in maintaining fluid temperatures. Foam insulation is applied around pipes and joints, providing a snug fit that not only prevents heat loss but also protects against condensation and freeze damage.

Another effective technique involves wrapping insulated jackets around the necessary components. These jackets serve as barriers, further reducing heat escape and enhancing energy conservation within the system. Materials used for jackets vary, but effective options include reflective foil and fiberglass, both designed to reflect heat back into the system instead of allowing it to dissipate. When properly implemented, these strategies can contribute significantly to the overall efficiency of solar thermal systems, ensuring that the maximum amount of captured solar energy serves its intended purpose.

4. PREPARATION OF JOINTS FOR CONNECTION

Preparing the joints adequately is an essential step in establishing secure connections in a solar thermal system. The integrity of the connections directly affects efficiency, making every facet of preparation noteworthy. Initially, ensuring that surfaces are clean and free of debris contributes significantly to the prevention of leaks and enhanced durability. Any contaminating particles can create weak points in the joint, thus risking both efficacy and safety.

Several techniques can be used for preparation, including measuring and cutting pipes accurately. Precision is vital; thus, a reliable measuring tool should be used to ensure proper alignment. When cutting piping materials, it’s essential to make smooth cuts without edges, as any irregularities can lead to improper fittings. Additionally, the edges should be deburred to eliminate sharp sections that might damage the seals, creating further vulnerabilities.

Once the pipes are prepared, applying the appropriate sealant or adhesive consistent with the materials used is crucial. Special attention should be given to following manufacturer instructions regarding adhesive application, as improper techniques may compromise the effectiveness of fittings. The overall effectiveness of the thermal connection not only depends on material choices but is equally contingent upon the preparation techniques applied throughout the process.

5. RELIABLE FASTENING TECHNIQUES

Following adequate preparation, employing reliable fastening techniques becomes imperative to creating robust connections in a solar thermal system. These fastening methods ensure that all components remain securely in place, minimizing the risk for leaks or disconnections, which can compromise system integrity. A variety of fastening techniques are available, with a few gaining prominence due to effectiveness and practicality.

One widely accepted technique involves the use of compression fittings. These fittings require minimal tools and skill yet provide a reliable connection if installed correctly. They operate using a simple compression principle, securely holding components together by compressing rubber or plastic seals against the fitting. Regular monitoring should be conducted to ensure that no leakages occur over time due to wear or environmental changes.

Soldering remains another popular technique when using metal piping, particularly copper systems. This method entails joining two components through melting a filler metal to create a strong and durable bond. While soldering may require more skilled labor and appropriate safety precautions, it establishes a robust connection resistant to heat fluctuations and pressure changes. Proper training ensures that soldering is completed to industry standards, creating reliable joints that contribute significantly to the effectiveness of solar thermal systems.

6. COMMON ISSUES WITH SOLAR THERMAL CONNECTIONS

Despite taking precautions and following established techniques, issues may still arise with the connections within solar thermal systems. Identifying and addressing these common problems proactively can save on repairs and system downtimes, ensuring that the setup operates effectively.

Among the frequent issues faced is the presence of leaks at the joints. Such inaccuracies may arise if the components are misaligned, improperly prepared, or incorrectly fastened. Even minor leaks can have significant repercussions, leading to potential efficiency losses and equipment damage. A thorough inspection regime is advisable to ensure that any leaks are addressed immediately to prevent further complications.

Another common issue is thermal expansion, which involves the natural expansion and contraction of materials in response to temperature changes. This phenomenon can lead to stress points at joints, causing them to weaken over time. Utilizing flexible joints or expansion joints when appropriate can mitigate these effects, contributing to the durability of the overall system. Addressing these challenges proactively improves the longevity of the system and enhances its efficiency while ensuring optimal performance.

7. MAINTAINING SOLAR THERMAL CONNECTIONS

Maintenance plays a vital role in ensuring that solar thermal connections function optimally throughout their operational lifespan. Regular inspections are fundamental to identifying potential issues before they escalate into significant problems. Consider incorporating periodic reviews of joints, insulation, and overall equipment status into a routine maintenance schedule.

During inspections, checking for signs of leaks, corrosion, or material fatigue is essential. Unexpected visual signs such as discoloration or surface degradation can indicate underlying problems that need immediate attention. Employing preventive measures, such as applying corrosion inhibitors or ensuring proper drainage, contributes further to the durability of solar thermal connections.

Documenting maintenance activities is also beneficial, offering insights for future reference. This can help in identifying recurrent issues and streamline troubleshooting efforts, ensuring a well-operating system. Proactive maintenance not only extends the life of solar thermal connections but also maximizes energy efficiency, enabling users to reap the full benefits of their solar thermal systems.

8. ECONOMIC AND ENVIRONMENTAL IMPACTS

Solar thermal systems present notable economic and environmental advantages compared to traditional energy sources. The implications of these installations extend beyond immediate cost savings; they contribute significantly to global efforts in combating climate change. With rising energy prices and increased awareness regarding environmental issues, more individuals and businesses are recognizing the value of adopting renewable energy solutions.

Financially speaking, the installation of solar thermal systems can lead to substantial savings over time. Reducing dependency on conventional energy sources lessens the financial burden associated with utility bills. Furthermore, government incentives often accompany the installation of solar thermal systems, providing significant tax breaks or rebates, thus making them more appealing.

From an environmental perspective, the transition to solar thermal technology helps reduce the reliance on fossil fuels, thereby decreasing greenhouse gas emissions. Utilizing renewable resources preserves existing ecosystems and conserves natural resources for future generations. Solar thermal energy plays a crucial role in mitigating climate change and promoting sustainable energy practices, making it imperative for societies to invest in and support these systems.

FAQs

WHAT ARE THE PRIMARY BENEFITS OF SOLAR THERMAL SYSTEMS?

Solar thermal systems provide numerous advantages, including renewable energy utilization, reduced utility costs, low maintenance, and environmental conservation. By harnessing sunlight, these systems offer a sustainable energy solution, effectively diminishing reliance on fossil fuels. In financial terms, cost savings can accumulate over time as solar energy significantly lowers household heating bills. Additionally, the low maintenance requirement allows homeowners more time for other pursuits, as few components necessitate frequent monitoring and repairs. Environmentally, solar thermal systems reduce carbon emissions, benefiting ecosystems and contributing to combating climate change efforts.

Moreover, installing solar thermal technology can create job opportunities in installation and maintenance, further boosting local economies. Whether applied in residential, commercial, or industrial contexts, solar thermal systems showcase versatility, embodying cutting-edge technology aimed at ushering societies toward sustainable energy futures.

HOW CAN I ENSURE THE LONGEVITY OF MY SOLAR THERMAL CONNECTIONS?

To ensure the longevity of solar thermal connections, regular inspections, routine maintenance, and selecting high-quality materials are essential. Inspecting for leaks, corrosion, and signs of wear can help identify potential concerns early, allowing for timely interventions before issues escalate. Maintenance practices, such as insulating joints and applying protective coatings, significantly enhance durability and operational efficiency.

Additionally, safeguarding installations from external influences like extreme temperatures or physical impacts contributes to their longevity. Opting for reputable manufacturers who provide quality components further bolsters the resilience of connections. Following manufacturer guidelines during installation and seeking assistance from certified professionals can mitigate risks associated with operational failures. Proper care, vigilance, and attention to detail result in extending the lifespan of solar thermal connections.

WHAT SHOULD I DO IF I DISCOVER A LEAK IN MY SOLAR THERMAL CONNECTION?

Discovering a leak in your solar thermal connection demands prompt and systematic action to mitigate potential damage. First, turn off the system to prevent further fluid loss and evaluate the extent of the leak. If possible, identify the source of the problem, whether it’s related to joint misalignment, corrosion, or compromised materials.

Once the issue has been located, consult manufacturer instructions or a seasoned technician for appropriate repair methods. Depending on the severity of the leak, you may need to replace damaged components, reseal joints, or reinforce connections. After addressing the issue, take time to review the entire system for any additional concerns that may need attention.

Following repairs, it is crucial to conduct thorough tests to confirm that the issue has been fully resolved and that no further leaks are present. Establishing a routine inspection schedule can help identify potential vulnerabilities early, ensuring that your solar thermal system remains efficient and functional for years to come.

The installation and connection of solar thermal barrel joints is a vital part of leveraging solar energy for heating purposes. Each element, from materials used to fastening techniques, impacts the system’s overall performance and efficiency. The methodology adopted not only minimizes heat loss and improves durability but also addresses common issues proactively. Maintaining these connections through regular inspection further enhances system functionality, ensuring that it operates effectively over time. Additionally, the financial and environmental benefits make solar thermal technology an attractive investment. By understanding and addressing the complexities within solar thermal systems, users can maximize their operational efficiency and contribute to a sustainable energy future. Ultimately, the intricate design of solar thermal barrel joints serves as a critical cog in the larger machinery of renewable energy utilization, elevating the importance of robust and well-maintained connections in achieving successful outcomes.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-thermal-barrel-joint/