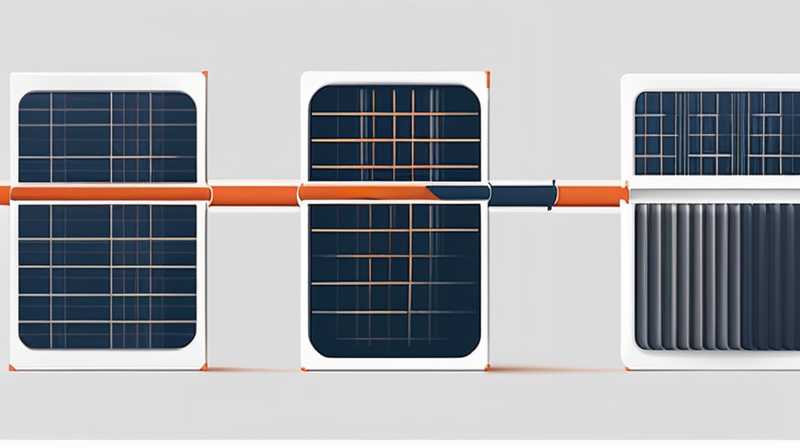

1. DIRECT ANSWER TO THE QUESTION: Connecting the solar tee pipe joint involves several precise steps to ensure an efficient and leak-free assembly designed to optimize solar energy transfer. 2. Proper tools and materials are essential; 3. Ensure correct alignment of the pipe; 4. Use appropriate sealants and fittings for compatibility. Each of these components guarantees that the entire system operates smoothly, facilitating the flow of heated water in solar heating applications.

1. TOOLS AND MATERIALS REQUIRED

When embarking on the installation of a solar tee pipe joint, gathering appropriate tools and materials is fundamental to ensure a seamless assembly process. The selection of these resources directly affects the longevity and efficiency of the solar heating system. Essential tools include pipe cutters, wrenches, and a heat gun, while materials such as PEX pipes, copper fittings, and Teflon tape are vital. Each tool serves a specific purpose; for instance, pipe cutters enable precise cuts without damaging the pipe integrity.

Understanding the types of piping systems in use is equally important. Various materials—such as PVC, copper, and PEX—cater to different strengths, thermal properties, and flexibility requirements. Employing heat-resistant materials can prevent leaks and degradation of structural integrity when exposed to high temperatures.

Having these components organized before starting the installation can significantly decrease the time spent troubleshooting and prevent unnecessary interruptions during the assembly. Accessibility to high-quality and compatible components cannot be overstated, as these affect not only the immediate installation but also the overall functionality of the system long-term.

2. PREPARATION OF PIPES AND COMPONENTS

Prior to making any connections, thorough preparation of all pipes and components is necessary to ensure a clean and effective assembly. This involves cleaning the ends of the pipes where connections will be made, which is vital for achieving a strong bond between the fittings. Debris, dust, or moisture can significantly diminish the capability of the adhesives and sealants to create a lasting hold.

Utilizing appropriate cleaning agents ensures that all residues are eliminated. For copper fittings, a wire brush may be used to clear oxidation, while for plastic pipes, a simple cloth may suffice to wipe off dirt. A clear and uniform connection surface will pave the way for better adhesion.

Moreover, verifying the compatibility of each component before commencing the assembly is vital. Not all pipe types fit neatly together, and the wrong pair might lead to leaks or system failures down the line. Having a comprehensive understanding of the manufacturer’s recommendations regarding fittings, sealants, and the types of pipes to use can enhance the durability of the connections being made.

3. ALIGNMENT OF PIPES AND JOINTS

Correct alignment of the pipes and joints cannot be overstated, as it is essential for ensuring the entire assembly is leak-free and functions as intended. Misalignment can lead to unnecessary wear and tear on joints, causing potential future issues that may require disassembly and repair. Ensuring that the tee joint is level and correctly oriented towards the expected water flow is imperative.

Using a level and tape measure to confirm that all components are straight will eliminate complications born from angles that deviate from the designed specifications. This phase may involve temporary clamps to hold the pipe in position until permanent assembly occurs, which aids in visual confirmation of fit.

Additionally, checking the specifications for the angle and length of piping required for the project can prevent alterations post-installation. Having detailed plans or diagrams that guide the installation process creates a roadmap for success and minimizes errors associated with initial measurements or placements.

4. CONNECTING THE TEES AND JOINTS

Once preparation and alignment are finished, the primary function of making the actual connections can begin. This means attaching the tee joints directly to the piping sections. For soldered connections using copper fittings, proper heating and the right amount of solder should be utilized. The heat gun allows for precise temperature control, preventing pipes from becoming warped and ensuring that the fittings achieve a robust bond.

In contrast, using PEX fittings will involve inserting the pipe into the joints and utilizing crimping tools to create a secure fit. It is imperative to follow the manufacturer’s guidelines regarding the crimping technique and spacing to ensure a reliable connection.

After securing the joints, letting the sealants or solder cool and set is crucial. Holding connections under pressure too soon can cause complications, leading to weak joints or leaks. Ensuring ample time is given for any adhesives or solder to cure before the system is activated will maximize both durability and performance.

5. SEALANTS AND ADDITIONAL ADJUSTMENTS

After establishing connections, applying sealants can further improve the integrity of the system by creating an additional layer of protection against any potential leaks. Choosing the appropriate type of sealant based on piping materials is crucial; silicone sealants, for example, readily cater to a variety of surfaces. Prioritize products designed for high-temperature applications to withstand the heat generated within solar systems.

During installation, ongoing inspections should occur to confirm that no foreign materials have compromised the connections or fittings. Addressing any oversight immediately can save undue complications later. Moreover, ensuring both the pipes and the joints are correctly assessed means that any misalignments or excessive force are dealt with before progressing.

Implementing routine checks on the connections after the system becomes operational is vital. Periodic maintenance reviews can catch unanticipated wear and tear early, ensuring the longevity of the entire solar system. Such diligence can lead to a more efficient and lasting energy operation for all involved.

6. PRESSURE TESTING AND USAGE

Once all fixtures are installed and deemed secure, conducting pressure tests is a wise final measure. Applying water pressure through the system can reveal weaknesses or incorrect fittings that may otherwise remain unnoticed. Engaging in this step allows for immediate rectification of any issues before the system goes live.

Monitor for signs of leaks; it is advisable to check for dampness around the joints and along the piping. Any signs of failure in a pressure test warrant re-evaluation of the installation to rectify misalignments or apply additional sealants as needed. Such thorough testing will provide peace of mind that the system is reliably operational and can efficiently transport heated water.

Once confirmed leak-free, activate the system while remaining observant of any unusual deviations in operation. Establish measures for longevity and efficient provision of solar energy, ensuring that functionality is optimal from the outset. Adopting such practices will promote sustainable and cost-effective energy use.

7. COMMON PITFALLS AND HOW TO AVOID THEM

Having knowledge of the common pitfalls encountered during the installation of a solar tee pipe joint can be incredibly beneficial. Failing to consider temperature fluctuations can lead to expansion or contraction of pipes, causing leaks. It is important to consider allowances for thermal changes, which can dramatically affect plastic materials in heating systems.

Furthermore, underestimating the importance of thorough cleaning can lead to inadequate seals, requiring rewiring and repairs. Direct attention to thoroughness can pay significant dividends by preventing would-be headaches down the line. Partial or rushed installations can always yield complications that may lead to costly fixes.

Educating oneself about the different piping options and their specifications can also mitigate the risk of improper fittings. Engaging in continuous learning—through either literature or hands-on training—enhances one’s competency in installation efforts.

8. SAFETY PRECAUTIONS DURING INSTALLATION

Safety measures during the connection of solar tee pipe joints should never be overlooked. Wearing appropriate protective gear, such as gloves and goggles, can mitigate the risk of injury from sharp edges or hot surfaces. Additionally, adhering strictly to safety guidelines regarding the power and heat tools involved in the installation process is essential for preventing accidents.

It is imperative to also consider the environmental ramifications during the assembly procedure. Ensuring that all materials are disposed of or recycled in accordance with local regulations promotes responsible practices that benefit both the ecosystem and community. Furthermore, being diligent about working within established guidelines will minimize risks during the work process.

Also, utilizing tools and equipment in accordance with their operational guidelines enhances both safety and efficiency. Proper skill development in managing these aspects will secure a successful connection, ensuring a reliable solar heating system.

FREQUENTLY ASKED QUESTIONS

WHAT TYPE OF PIPE IS BEST FOR SOLAR THERMAL SYSTEMS?

When selecting materials for solar thermal systems, several options are available, with each offering distinct advantages. Copper piping is often favored due to its excellent thermal conductivity and durability, which can withstand high-pressure scenarios. However, its cost may pose a barrier for some projects.

Conversely, PEX is growing in popularity because it is lightweight, easier to install, and resistant to corrosion, making it ideal for those facing budget constraints. Notably, PEX can flex and expand, mitigating the risks of cracking during temperature fluctuations, which is particularly crucial in solar applications where temperatures can frequently vary.

In essence, the choice of material largely depends on the specific needs of the project, budgetary considerations, and expected operational conditions. Additionally, local building codes may dictate specific requirements regarding pipe choice that should not be overlooked.

HOW CAN YOU ENSURE LEAK-FREE CONNECTIONS IN SOLAR SYSTEMS?

To ensure connections remain leak-free in solar thermal applications, numerous techniques must be employed. Beginning with proper installation techniques is vital; this includes cleaning the pipe ends thoroughly before applying any sealants, as residues can weaken bonds. Using the correct type of sealant tailored to the piping material enhances the ability to prevent leaks.

Soldering techniques, if used, must be executed with precision to establish strong connections. Likewise, crimping PEX pipes should be performed to the standards set by manufacturers to create a reliable fitting. Thorough pressure testing of the entire system following installation provides another level of assurance.

Moreover, maintaining and monitoring the connections over time promotes ongoing awareness of any potential degradation or issues that may develop. Engaging in periodic assessments allows for quick resolution of problems before they escalate into severe leaks or system failures.

HOW OFTEN SHOULD SOLAR THERMAL CONNECTIONS BE INSPECTED?

Regular inspection of solar thermal connections is recommended to maintain optimal operation of the system. Ideally, the entire system should undergo a thorough examination at least once a year to identify any wear or damage that could compromise performance. This includes checking fittings, seals, and pipes for signs of leaks or corrosion.

Furthermore, it may be prudent to conduct additional checks after any significant migration of the system, environmental changes, or extreme weather events. Regular assessments not only prolong the life of the system but can also enhance the efficiency of the solar thermal energy collection and transfer processes.

Such vigilance serves as a proactive approach, allowing any minor issues to be addressed before they escalate into costly repairs or system-wide failures, maximizing energy production efficiency and ensuring continued benefits from the solar investment.

INSTALLATION OF SOLAR TEE PIPE JOINTS REQUIRES A THOROUGH UNDERSTANDING OF BOTH TECHNIQUE AND MATERIALS. All steps—ranging from preparation of components, to careful alignment, to the secure connection of fittings—play critical roles in ensuring that the system operates efficiently and effectively. Proper training and knowledge of tools and safety precautions enhance the entire installation process. By employing reliable materials and adhering to precise procedures, any individual or professional can connect solar tee pipe joints that contribute to a sustainable and eco-friendly energy solution. Additionally, regular inspections and proactive maintenance will further ensure the longevity and optimal performance of these systems. Thus, commitment to these best practices transforms challenges into opportunities for enhancing the utilization of renewable energy sources, benefitting both users and the environment alike.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-tee-pipe-joint/