To connect a solar solenoid valve to an air pipe requires careful attention to detail and an understanding of both plumbing and electrical systems. 1. Identify the proper components, 2. Understand the function of the solenoid valve, 3. Ensure compatibility with the air pipe system, 4. Follow secure installation protocols. The solenoid valve serves as an efficient tool for controlling the flow of air in pneumatic systems; it utilizes electromechanical action to open or close an air supply. For a successful installation, the solenoid’s specifications must match those of the air pipe and any associated machinery to maintain optimal functionality.

1. UNDERSTANDING SOLENOID VALVE FUNCTIONS

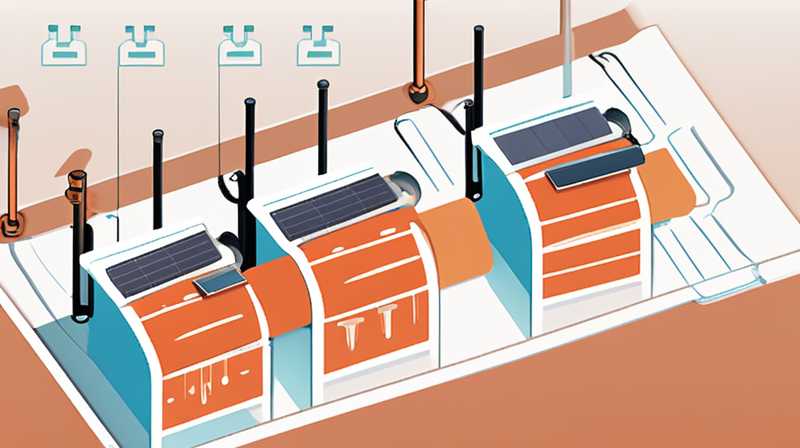

Solar solenoid valves play a critical role in managing air supply in various pneumatic operations. These devices use electrical power to control air flow through a mechanism that transitions between open and closed states. In the context of solar operations, they are instrumental in integrating renewable energy into pneumatic systems, allowing for automated control without the need for extensive external power sources.

When selecting a solenoid valve, it is paramount to consider the operation’s specific demands. For instance, a solenoid valve must be rated for the correct pressure range and compatible with the fluid type—air in this case. A common oversight is neglecting the appropriate size of the valve in relation to the air pipe, which can cause significant inefficiencies in the system. Therefore, understanding the valve’s role, as well as the entire pneumatic system’s requirements, is crucial for establishing a reliable connection.

2. COMPONENTS REQUIRED FOR CONNECTION

Before proceeding to the connection process, it is essential to gather all required components. The primary items include the solar solenoid valve, compatible fittings, an air pipe, necessary tools for installation, and electrical connections. Having a comprehensive list of materials simplifies the installation process and prevents interruptions due to missing elements.

The choice of fittings and connectors is equally important, as the wrong size or type can lead to leaks or system failure. Materials used for the air pipe and fittings should withstand the operation’s pressure and temperature conditions, whether plastic, metal, or a composite. Each connection point must also ensure a tight seal to maintain pressure integrity throughout the pneumatic system, safeguarding against air loss that could hinder equipment performance.

3. THE INSTALLATION PROCESS

The installation of the solar solenoid valve to the air pipe requires adherence to several critical steps. First and foremost, identify the optimal location for mounting the valve, ensuring that it is accessible for future maintenance while being shielded from environmental concerns. Confirm that the power source—typically solar panels or a battery system—is adequately configured to supply the solenoid’s operational requirements.

To begin the connection, it is necessary to shut off any existing air flow within the pipe system to maintain safety. Following this, the solenoid valve should be aligned with the air pipes and fitted accordingly, ensuring all threads match up correctly to prevent disconnections during operation. While tightening connections, excessive force should be avoided as this could compromise the integrity of both the valve and the pipe. It’s also advisable to apply Teflon tape or pipe sealant on threaded connections to enhance sealing and prevent leaks.

4. ELECTRICAL CONNECTIONS

Electrical connections play a pivotal role in the proper functionality of the solar solenoid valve. Ensure that the wiring is robust and compliant with electrical codes, as this encompasses both efficiency and safety within the system. Consistently using high-quality wires will help mitigate the risks of shorts or disconnections that may render the system nonfunctional.

Wiring should be connected to the valve according to the manufacturer’s specifications, as different models may require unique wiring setups. Once the electrical connections are made, it is prudent to check the system’s voltage and amperage with a multimeter, ensuring there are no discrepancies that could lead to damage. Any inconsistencies should be addressed before proceeding to test the operational status of the entire setup.

5. TESTING AND TROUBLESHOOTING

After completing the installation, the next logical step is to put the system through its paces. Activate the solar power source and allow the solenoid valve to receive the electrical signal for operational testing. Observe the system for any irregularities in air flow—specifically, whether the valve opens and closes as intended.

If problems arise, such as a failing solenoid or disrupted air flow, troubleshooting should commence. Common issues may include electrical faults, incorrect wiring setups, or compatibility issues between the valve and the air pipe. In such cases, reviewing the installation process for adherence to guidelines can help identify points of failure. Documenting any anomalies and corresponding fixes can help in future installations and improve overall efficiency.

6. MAINTENANCE AND LONGEVITY

To ensure the longevity of the solar solenoid valve and the air pipe connection, regular maintenance checks are paramount. These should include inspecting all fittings for leaks, testing electrical connections for integrity, and replacing any worn-out components promptly. By adhering to a proactive maintenance schedule, the likelihood of sudden failures can be significantly reduced.

Cleaning the valve and surrounding components is essential, particularly in harsh environments where dust and debris can accumulate. Establishing a routine cleaning regimen, as well as checking for corrosion or wear, will not only extend the lifespan of the equipment but will also enhance its performance in critical situations.

FAQs

WHAT IS A SOLENOID VALVE?

A solenoid valve is an electromechanical device utilized to control the flow of liquids or gases within a system. This valve is operated by an electromagnetic solenoid, which, when energized, creates a magnetic field that moves a plunger within the valve body, allowing or blocking flow. In pneumatic systems, like those using air pipes, the solenoid valve regulates air flow based on the principles of electromechanical action. It is pivotal in various applications, including irrigation, HVAC systems, and automated processes, offering precise control over fluid dynamics, often enhancing efficiency in operations. Proper understanding of solenoid valves ensures better installation and maintenance, leading to robust and reliable functionality whenever required.

HOW DO I INSTALL A SOLENOID VALVE TO A PNEUMATIC SYSTEM?

Installing a solenoid valve to a pneumatic system involves several key steps. Initially, ensure the work area is clear and safe, then gather necessary materials including a correctly sized solenoid valve, appropriate fittings, and tools. Begin by shutting off the air supply to avoid pressure build-up, and carefully align and connect the valve with the air pipe using compatible fittings. Attention should also be directed to electrical connections; once installed, test the solenoid’s operation with input from the power source. Regular inspections and maintenance will also contribute to the longevity and efficiency of the system. Following a clear process ensures that the valve operates effectively, optimizing the overall pneumatic system’s functionality.

WHAT ARE THE COMMON PROBLEMS WITH SOLENOID VALVES?

Common problems with solenoid valves include electrical malfunctions, leakage, and improper actuation, which can result from a series of causes. For electrical issues, check the power supply and wiring connections—faulty connections can prevent the solenoid from operating correctly. Leakage may arise from worn-out seals or poor fitting, requiring immediate inspection and potential replacement. Additionally, ensuring that the correct valve size and type suitable for the application is crucial. A thorough understanding of these issues can help in prompt troubleshooting and effective maintenance strategies, securing the valve’s operational reliability over time.

The Importance of Proper Installation and Maintenance

Executing the connection of a solar solenoid valve to an air pipe is not just a matter of following mechanical steps; it encompasses an understanding of how all components interact within a pneumatic system. Properly managing the flow of air through such systems enhances performance, minimizes waste, and promotes sustainability, especially when utilized in renewable energy setups. Each facet, from selecting adequate materials to performing precise electrical setups, contributes significantly to the installation outcome. Moreover, adhering to a routine maintenance schedule is essential, ensuring continued efficiency and reliability of the system.

The implications of malfunctions or improper installations can be extensive, leading to inefficiencies and substantially increased operational costs over time. Investing the time and resources into a thorough and thoughtful installation process ultimately pays dividends in system performance and longevity. With increasing reliance on renewable energy sources globally, understanding the integration of such technologies into existing infrastructures is paramount for anyone engaged with or relying on pneumatic systems. Becoming adept in these practices yields substantial benefits—both environmentally and economically—creating a sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-solenoid-valve-to-the-air-pipe/