To successfully connect a solar solenoid valve when it has sustained damage, it is crucial to follow systematic steps ensuring functionality and safety, as well as understanding the device’s components to avoid further issues. 1. Assess the damage, 2. Gather necessary materials, 3. Follow a detailed installation guide, 4. Test the connection thoroughly. The importance of proper assessment cannot be understated, as it lays the foundation for whether a repair is feasible or if complete replacement is necessary. Assessing physical signs of damage, electrical continuity, and compatibility with existing systems are essential steps that empower the user to make informed decisions regarding the course of action to be taken.

1. UNDERSTANDING SOLENOID VALVES

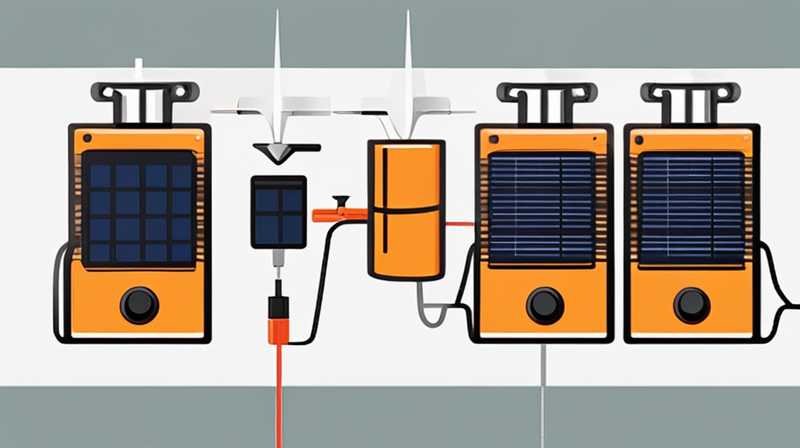

To comprehend the methodology behind connecting a solar solenoid valve, one must be familiar with its basic operation and components. Solenoid valves serve as electromechanical devices used to control the flow of liquids or gases. They are predominantly employed in automated systems and play an integral role in irrigation, heating, and cooling systems. By converting electrical energy into mechanical movement, solenoids enable the opening and closure of valves with precision.

There are various types of solenoid valves, including two-way and three-way valves, each serving distinctive functions. Two-way valves control the flow of fluid in a single direction, while three-way valves can redirect flow and mix fluids. Understanding the specific configuration of the valve in question is paramount for successful installation or repair.

2. IDENTIFYING THE DAMAGE

Determining the extent of the damage is a critical step before attempting any kind of connection or repair. Visual inspections should be prioritized, focusing on the wiring, electrical connectors, and the solenoid coil itself. Look for signs of fraying, discoloration, or burns, which may indicate electrical failure or overheating. Additionally, ensure there are no external physical damages to the valve body that would impede its functionality.

Moreover, the functionality of the valve must also be assessed. This can be achieved through testing for electrical continuity with a multimeter. If the solenoid does not conduct electricity, it may indicate a malfunction that warrants replacement. Accurate identification of damage not only helps in determining whether repair is feasible but also informs the user about the necessary materials and tools to rectify the issue.

3. GATHERING NECESSARY MATERIALS

Once the damage is assessed and a decision is made on whether to repair or replace the solenoid valve, it is time to gather the requisite materials. The primary requirement is the solenoid valve itself, whether original equipment manufacturer (OEM) or compatible aftermarket components. Additionally, one should also have on hand essential tools such as screwdrivers, wire strippers, electrical tape, and heat-shrink tubing for insulation purposes.

Furthermore, having a multimeter is crucial for testing continuity once the repairs or connections are made. Additional supplies may include connectors and terminals specifically designed for the wire gauge being used. Ensuring that all necessary materials are organized before starting the process can dramatically reduce the overall installation time, enhancing efficiency and quality of work.

4. REPAIR OR REPLACE

Depending on the extent of the damage assessed earlier, one must decide whether repairing or replacing the solenoid valve is the best course of action. In many cases, replacing a damaged or malfunctioning valve is the preferred option, especially when the cost of repairs exceeds the price of a new valve. However, minor damages such as frayed wires or disconnected terminals often lend themselves to repair.

If opting for a repair, ensure that all solder joints are secure and that any damaged wires are properly stripped and connected. Proper insulation of connections using electrical tape or heat-shrink tubing is essential to prevent further electrical issues. Conversely, if a replacement valve is selected, proper disconnection of the old valve and careful installation of the new one must be conducted in accordance with the manufacturer’s installation guidelines.

5. INSTALLATION PROCESS

Once the decision to repair or replace has been reached, the installation process can commence. Begin by disconnecting the power supply to the valve to prevent electrical shock or short circuits. This step is crucial for safety; without disconnecting the power, undesired consequences may occur during the installation process.

If replacing the valve, remove the old unit by unscrewing it from its mounting point, while ensuring that any associated plumbing is also disconnected. Care should be taken to avoid damaging surrounding components during this removal. After successfully removing the valve, clean the area to remove any debris or buildup that could obstruct the installation of the new valve.

With the area prepared, install the new unit by securing it in place according to the designated mounting points and reconnecting the associated plumbing. Ensure that all existing electrical connections meet compatibility standards and are tightened appropriately.

6. TESTING THE CONNECTION

After successfully installing the solenoid valve, conducting a thorough test is vital to confirm that everything functions correctly. Reconnect the power supply and observe whether the valve operates as expected. Activating the control mechanism, whether through a switch or automation system, should initiate the opening and closing of the valve effectively.

To further confirm that there are no leaks or electrical issues, carefully inspect the entire installation for any signs of malfunction. Testing should include running the associated system, whether it be irrigation or heating, to verify that the solenoid valve performs its intended function consistently. If any abnormalities are present during testing, revisit the connections and repair them as necessary.

7. TROUBLESHOOTING COMMON ISSUES

Despite meticulously following installation instructions, some common complications may arise with solenoid valves. Identifying and rectifying these issues promptly can prolong the lifespan of the valve and ensure optimal performance. One prevalent problem could be the valve failing to open or close, potentially stemming from electrical issues or blockages.

Another common issue is leakage, which could be caused by improper sealing during installation or hardware malfunctions. In such cases, double-checking all connections and using appropriate sealants when needed will usually correct the problems. Consulting the valve’s technical documentation may provide additional troubleshooting steps tailored to the specific model.

8. MAINTENANCE OF SOLENOID VALVES

A proactive maintenance regimen ensures longevity and functionality for solenoid valves in any system. Routine inspections should encompass checking all electrical and mechanical connections, looking for signs of wear, corrosion, or damage. Maintenance should also include routine cleaning of the valve and its surrounding area to prevent buildup that could impair performance.

When conducting maintenance, maintaining a clean environment surrounding the solenoid valve is crucial; contaminants can hinder efficiency and lead to premature failure. Adequate maintenance not only prolongs the life of the valve but also maximizes its effectiveness within the system it is integrated with.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS OF A FAULTY SOLENOID VALVE?

A malfunctioning solenoid valve can exhibit various indicators. Common signs include inability to open or close properly, leaks around the valve body, and the accompanying electrical and fluid systems failing to operate correctly. Observing erratic operation within the connected system can often signal a solenoid issue.

If the valve is making unusual sounds, such as buzzing or clicking, that could denote a power issue. Moreover, using a multimeter to check electrical continuity can confirm whether power supply and functionality are intact. Regular observation of these markers plays an essential role in proactive maintenance and timely problem resolution.

HOW DO I CHOOSE THE RIGHT SOLENOID VALVE?

Selecting an appropriate solenoid valve entails considering several factors. Evalutate the application requirements, including fluid type, pressure, and voltage specifications. Each application has unique demands, resulting in the necessity for specific characteristics in a solenoid valve.

Another consideration is the valve’s orientation and the compatibility with the existing piping or electrical system. Consulting manufacturer specifications and guidelines provides valuable insights into best practices for selection. Proper choice can enhance system reliability and effectiveness while preventing early failures or inefficiencies.

HOW OFTEN SHOULD I MAINTAIN MY SOLENOID VALVE?

Maintenance frequency is subject to various factors, including system usage, environment, and specific application. Typically, a routine inspection should occur at least once every six months, or more frequently in high-use or harsh environmental conditions. Regular checks ensure early detection of potential issues, contributing to prolonged functionality.

Moreover, keeping a maintenance record of inspections and repairs provides insights into performance patterns and helps identify any future concerns. Establishing a consistent schedule based on specific operational needs is critical for optimal performance overall.

Replacement or repair of a solar solenoid valve is fundamentally a process that requires careful consideration, detailed understanding, and methodical execution. By performing thorough assessments, utilizing correct materials, and adhering to proper installation protocols, one can ensure that solenoid valves operate effectively and maintain their integral roles in irrigation, heating, or other systems. The implications of these devices are significant, impacting both efficiency and energy conservation. Proactive maintenance, adequate troubleshooting, and comprehensive knowledge will not only enhance your capability to repair or replace these devices but also escalate the lifespan of the components in your system. By understanding how to properly connect an impaired solar solenoid valve and configuring it according to specifications, users can optimize performance and mitigate future issues that may arise. Whether undertaking repairs or engaging in proactive maintenance, a commitment to diligence will undoubtedly yield positive results, preserving the functionality and importance of solar solenoid valves within the respective systems they serve.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-solenoid-valve-if-it-is-broken/