1. Directly connecting solar power cables is essential for the efficient functioning of a solar energy system. 2. Proper cable connection techniques can enhance the system’s performance and safety. 3. The tools required for this task include wire cutters, strippers, connectors, and multimeters to ensure correct voltage and continuity. 4. It is crucial to adhere to local regulations and safety standards when connecting cables.

PREPARING FOR CONNECTION

Connecting solar power cables involves several preparatory steps to ensure a safe and efficient process. First, one must gather the necessary tools and materials. This includes solar connectors like MC4 connectors, wire strippers to prepare the wires, and crimping tools. Having these items at hand streamlines the entire operation. Additionally, wearing appropriate safety gear is crucial. This includes gloves to protect against electrical shock and safety goggles to shield the eyes from debris during cutting or stripping.

Prior to initiating the connection, it’s essential to familiarize oneself with the solar panel system’s components. Understanding how solar panels interact with inverters and batteries helps in the effective routing of cables. This knowledge allows for a greater grasp of the electrical flow within the system, ensuring that connections are not only accurate but also theoretically sound. Once the tools and understanding are in order, the connection process can proceed in a methodical manner, minimizing the risk of errors.

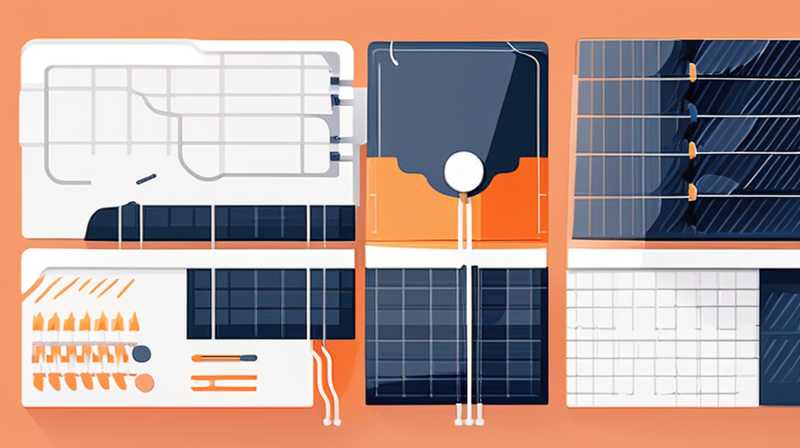

UNDERSTANDING SOLAR CABLE TYPES

Before embarking on connecting solar cables, it’s imperative to comprehend the various types of cables used in solar installations. The distinction primarily lies between DC cables and AC cables; each serves a different purpose within the solar energy system. DC cables transport electricity generated by the solar panels to the inverter while AC cables carry electricity from the inverter to the grid or home consumption. The materials used in these cables also affect performance.

Selecting the correct gauge is critical. For example, utilizing cables that are too thin can result in overheating, loss of energy, or potential fire hazards. Cables, therefore, need to be chosen based on the distance from the solar panels to the inverter and the expected load. Moreover, understanding the voltage ratings of cables is essential for both safety and efficiency. This is why it is often recommended to consult local guidelines concerning cable specifications.

STEP-BY-STEP CONNECTION PROCESS

The connection process generally unfolds in a series of sequential actions aimed at achieving a reliable setup. First, ensure that all systems are powered down. Disconnecting power prevents any risk of electrical shock while modifications are made. After ensuring power has been cut, begin by stripping the ends of the solar cables. Employ wire strippers to eliminate the insulation, exposing enough copper to permit a solid connection.

Focusing on the polarity of each wire is vital during this step. Positive and negative terminals must remain distinct, as incorrect connections can lead to significant damage. Once each cable has been stripped, connect them to the respective solar connectors. Employ a crimping tool to secure the connectors properly. A robust connection is paramount for ensuring conductivity and minimizing energy loss.

SECURE THE CONNECTION

After completing the initial connections, securing them becomes the next focus. Once the solar cables are attached to the connectors, applying heat shrink tubing can protect the connections. This tubing provides insulation from environmental debris and moisture, which are common threats to electrical systems. Heat shrink tubing expands upon application of heat, forming a tight seal that secures the exposed wire ends.

Check each connection for integrity by gently tugging them. Connections that feel loose may require re-crimping or even replacement. After inspecting, use cable ties or clips to organize and secure the wiring, ensuring that all cables are neatly bundled. A well-arranged solar cable system not only looks professional but also minimizes potential hazards caused by tangled or loose wires.

TESTING THE CONNECTION

Once the connections are secure, testing the installation is essential. Use a multimeter to measure the voltage output from the solar panels. This step confirms that the panels generate electricity and that the connections are effectively transmitting this energy. Both open-circuit voltage and short-circuit current should be monitored to ascertain proper function.

Should the readings be inconsistent or below expected levels, retracing steps to check each connection may be necessary. This process can reveal misalignments or faulty connections that must be corrected. Ongoing monitoring after the initial setup is also recommended. Regular checks of voltage output help ensure that the system continues to perform optimally.

MAINTAINING CABLE INTEGRITY

Maintaining the integrity of solar power cables is crucial for long-term efficiency. Environmental factors, such as UV exposure and moisture, can degrade cable insulation over time. Regular inspections for visible wear and tear or signs of corrosion will help in early detection of potential issues. Proper cable management, including strategic routing away from areas susceptible to physical damage, is equally important.

Consider employing protective conduits where cables are exposed to harsh elements. These conduits encase cables, providing an additional layer of defense against extreme temperatures or mechanical wear. Furthermore, ensuring that any connections at junction boxes are watertight can prevent moisture ingress, significantly extending the lifespan of the cable system.

INCREASING ELECTRICAL EFFICIENCY

To optimize the performance of a solar power system, it’s essential to ensure electrical efficiency. This involves not only quality connections but also appropriate cable length and routing. Minimizing the distance that electricity travels reduces potential losses. Thus, planning the layout of solar panels relative to inverters and battery systems is key to enhancing performance.

Additionally, judiciously selecting high-quality materials and components contributes to electrical efficiency. Investing in premium cables that possess lower resistance levels will yield a better overall output from the solar energy system. Occasionally reviewing and updating components based on technological advancements can yield substantial benefits. Ensuring cables are cleaned regularly can also assist in maintaining their efficiency.

MEETING SAFETY STANDARDS

Safety standards underpin every aspect of connecting solar power cables. Recognizing local regulations on electrical installations is paramount. Safety codes not only ensure compliance but also protect individuals and properties from hazards. Every component used—from cables to connectors—should meet established standards, ensuring reliability in performance.

Carrying out installations according to recommended practices will significantly reduce risks. Understanding the dangers associated with improper connections, such as short circuits or electrical fires, amplifies the importance of adhering to these guidelines. Seeking professional assistance or consulting with certified electricians, especially for complex systems, is a worthwhile consideration for achieving a safe installation.

FAQs

WHAT TO DO IF MY SOLAR CABLES ARE DAMAGED?

If solar cables are found to have physical damage, it is important to act swiftly. Begin by disconnecting power from the system to ensure safety. Inspect the extent of the damage to determine if a simple repair, such as re-insulation or splicing, is possible. If the damage is severe, replacing the affected cables is the safest route. When replacing cables, ensure that new components conform to relevant specifications, addressing any underlying issues that led to the damage in the first place. Moreover, consulting a licensed electrician could provide insights on the best practices for maintenance.

HOW OFTEN SHOULD SOLAR POWER CABLES BE INSPECTED?

Regular inspections of solar power cables should occur at least once a year. However, more frequent checks are recommended in regions facing extreme weather conditions. During these inspections, look for signs of wear, cracks, or loose connections. Additionally, any presence of corrosion or discoloration indicates potential problems that need to be addressed immediately. Keeping a log of inspections can also aid in recognizing patterns over time, leading to improved maintenance, and proactive replacements.

CAN I DO THE CONNECTION MYSELF, OR SHOULD I HIRE A PROFESSIONAL?

While some individuals may possess the skills required to connect solar power cables themselves, hiring a licensed professional is generally recommended. Professionals not only bring expertise to ensure that connections are accurate and compliant with local regulations, but they also have access to tools minimizing the risks involved. Moreover, having a qualified technician install the system can provide peace of mind. If opting to proceed independently, it’s crucial to research thoroughly and follow all safety guidelines to minimize dangers.

The process of connecting solar power cables is multifaceted yet highly manageable with the correct knowledge, tools, and approach. First, careful preparation and understanding of the components ensure a robust foundation is laid for a successful installation. Next, comprehending the types of cables and their function significantly informs the steps needed for effective connections. Moreover, implementing thorough testing and maintenance practices solidifies the connection’s reliability and safety, allowing one to harness the advantages of solar power efficiently. Ultimately, understanding how to connect these cables not only mitigates potential hazards but also promotes the sustainable use of renewable energy, aligning with modern environmental standards and reducing dependence on fossil fuels.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-power-cable/