1. Connection Process, 2. Importance of Proper Technique, 3. Common Challenges, 4. Tools Required

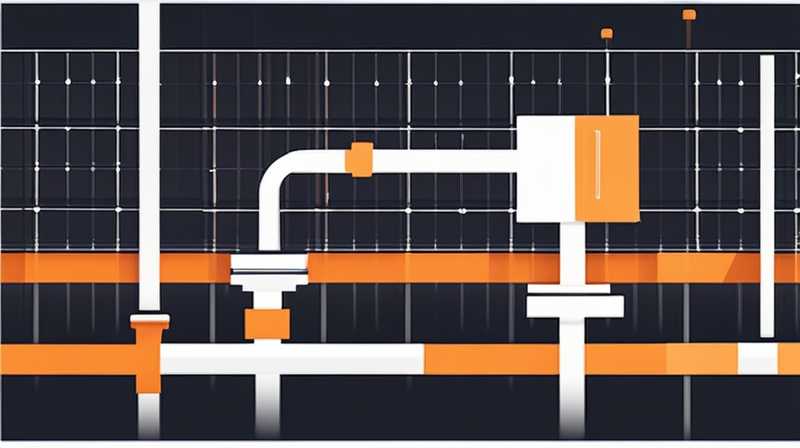

To connect a solar pipeline joint effectively, certain steps must be undertaken diligently. 1. Start by cleaning both ends of the pipeline; 2. Align the joints to ensure they fit properly; 3. Use the appropriate adhesive or sealing technique; 4. Allow the joint to cure and check for leaks. This process ensures a secure and efficient connection that contributes to the overall performance and longevity of the solar energy system. One critical aspect involves the right selection of materials. Many overlook the compatibility of the pipelines with the adhesive, leading to inefficiencies or even failures in the future. Using a high-quality joint sealer designed for solar applications can significantly enhance durability and prevent leaks, ultimately promoting a more robust energy system.

1. CONNECTION PROCESS

Establishing an effective connection between solar pipeline joints requires a series of methodical steps to be executed with precision. The first action involves cleaning the ends of the pipelines; this step is pivotal as any existing dirt, oil, or debris can hinder the bonding process. Using a clean cloth or a specialized solvent will help ensure that the surfaces are entirely free of contaminants. This task is often underestimated, but it is essential for achieving a strong bond.

Following the cleaning process, the alignment of the joints becomes a priority. Proper alignment is crucial as misaligned pipes can lead to stress on the connection, resulting in potential leaks or failure over time. Careful consideration should be given to the angle and orientation of each joint to make certain that they are sitting correctly against one another. Utilizing clamps or alignment tools can provide additional assistance in this phase, preventing any unintended shifts during subsequent steps.

Subsequent to achieving a clean and aligned connection, the application of adhesive or sealing material comes next. Select an adhesive that is designed specifically for solar energy systems, ensuring it can withstand fluctuations in temperature and exposure to UV light. The correct amount should be applied to both ends of the joint, as per the manufacturer’s instructions. Following this, a detailed inspection of the joint may be performed to verify that there are no gaps or areas where the adhesive was inadequately applied.

Finally, allowing the joint to cure is paramount. The recommended cure time will range depending on both the adhesive used and the environmental conditions. During this period, no stress should be applied to the joint, and thorough inspections should be conducted to check for leaks. Utilizing pressure testing methods can aid in scrutinizing the integrity of the connection, ensuring that it meets the requisite performance standards established for solar pipeline systems.

2. IMPORTANCE OF PROPER TECHNIQUE

The significance of employing the right techniques when connecting solar pipeline joints cannot be overstated. A well-executed connection not only optimizes the transfer of energy but also minimizes potential maintenance costs over time. Proper installation creates a stable and efficient pathway for the flow of fluids, which can significantly enhance overall system performance.

Neglecting to follow appropriate procedures can lead to a host of issues further along the line. For instance, poorly executed connections may result in leaks that can compromise the efficiency of the entire system. Such leaks can lead to energy loss and affect the components connected downstream, causing additional repairs or replacements that could have been avoided with proper technique. Furthermore, improper connections may lead to premature wear and damage to the pipelines, leading to costly replacements and downtime.

Another critical aspect surrounding the importance of proper techniques is safety. Solar energy systems carry inherent risks, especially when fluid dynamics are involved. An incorrectly assembled joint poses risks not only to the system itself but also to personnel operating or maintaining it. Any fluid leak could present a hazardous situation, particularly if the system involves hot fluids or other potentially dangerous substances.

The advanced techniques employed in connecting solar pipeline joints necessitate proper training and experience. Education regarding material compatibility, adhesive properties, and mechanical fitting techniques is vital for anyone involved in this process. It fosters an environment where technicians and engineers are confident in their ability to execute superior connections, thereby enhancing the overall reliability of solar energy systems.

3. COMMON CHALLENGES

Although connecting solar pipeline joints may seem straightforward, several common challenges can arise during the process. One prevalent issue pertains to material compatibility, where the pipelines and adhesives do not interact as intended. Such mismatches can lead to weakened joints, ultimately resulting in service interruptions or system failure.

To counteract this challenge, thorough research is necessary to ensure that the materials selected are suitable for the specific conditions they will face. Consultation with manufacturers often provides valuable insights into suitable combinations of materials and is a prudent measure to avoid future complications. Many technicians may underestimate the importance of checking compatibility; however, prioritizing it establishes a solid foundation for the connection process.

Another common challenge involves achieving the right alignment during installation. Ensuring that the joints align perfectly can often be a time-consuming task, demanding patience and precision. Misalignment can result not only in stress on the connection but also in uneven distribution of internal pressure, potentially leading to catastrophic failures. Using alignment tools specifically designed for pipeline applications can simplify this task and prevent errors.

Finally, environmental factors can play a significant role in the connection process. Temperature extremes, humidity levels, and exposure to sunlight may all affect both the installation and the long-term performance of the joints. For instance, during hot weather, the curing process of some adhesives can accelerate, leading to improper bonding. Understanding the specific requirements dictated by prevailing conditions is essential for achieving a reliable connection.

4. TOOLS REQUIRED

The successful installation of solar pipeline joints hinges on the selection and use of appropriate tools. Basic tools such as pipe cutters, adhesive application devices, and joint alignment tools form the foundation of any installation kit. Having the right tools readily available ensures efficiency throughout the entire process, allowing for a seamless connection.

When selecting pipe cutters, it is essential to invest in high-quality options that provide clean and precise cuts, which directly impact the quality of the joints. Rugged pipe cutters that can handle various materials, including PVC and metal, are advantageous as they promote uniformity in the connection surfaces. Properly prepared surfaces are instrumental in achieving a strong bond between the joint elements.

Adhesive application devices also merit significant consideration. Opting for precision applicators eliminates the risk of over-application, which can lead to challenges such as adhesive squeezing out from the joint during curing. Properly calibrated tools ensure that just the right amount is dispensed, while additionally allowing for consistent results across multiple connections.

Safety equipment should not be overlooked either. Having personal protective equipment (PPE), including gloves and safety goggles, safeguards personnel against injury while working with potentially harmful substances. Ensuring that workers are well-protected fosters a safer working environment, enabling them to focus solely on the task without undue concern for their wellbeing.

Additional specialized tools such as temperature gauges and leak detection devices can greatly enhance the efficiency of the connection process. Implementing temperature gauges to monitor the curing environment allows technicians to make necessary adjustments when external conditions are less than ideal. Leak detection devices assist in validating the integrity and safety of the completed connections before commissioning the entire solar energy system.

QUESTIONS

WHAT IS THE BEST ADHESIVE FOR SOLAR PIPELINE CONNECTIONS?

Selecting the appropriate adhesive for solar pipeline connections is crucial for ensuring longevity and effectiveness. The most applicable types include solvent-based adhesives, UV-resistant epoxies, and specific adhesives rated for the temperatures and chemicals associated with the fluids being transported. Each adhesive type possesses unique qualities that make it suited for different scenarios; therefore, understanding the operational environment is fundamental in making a choice.

Furthermore, an adhesive must not only bind effectively but also withstand outdoor elements such as temperature fluctuations and UV exposure. Many experts recommend products that have been specifically formulated for solar applications, as these materials are engineered to resist degradation even under prolonged sunlight exposure. Always consult technical datasheets and product specifications to ensure that the chosen adhesive matches both the material properties and operational requirements.

CAN I USE PVC ADHESIVES ON OTHER TYPES OF PIPE?

Customarily, PVC adhesives are intended for use exclusively with PVC materials and should not be mixed with other types of plastics or metals unless explicitly stated by the manufacturer. Using PVC adhesives on other pipe materials can lead to ineffective bonding and a heightened risk of failure or leaks. Each type of adhesive is formulated for specific chemical makeup and physical properties of the respective materials.

When considering alternatives, it is advisable to investigate adhesives that are designated for multisubstrate applications. Such adhesives have the versatility to bond a variety of materials while maintaining robust performance features. Specific instructions provided by the adhesive manufacturers should always be followed to avoid compromising system integrity.

HOW CAN I DETECT LEAKS IN SOLAR PIPELINES?

To ensure the integrity of connected solar pipelines, employing leak detection methods is essential. Techniques include pressure testing, visual inspections, and the use of advanced electronic leak detection systems. Pressure testing can often highlight weak points in the joints, providing immediate feedback on potential issues.

Conducting routine maintenance and checks after installation is also necessary. Visual inspections can reveal signs of leaking, such as discoloration, dampness, or erosion around joint areas. Moreover, integrating electronic detection systems can allow for real-time monitoring, providing timely alerts should any leaks occur. Combining these strategies forms a robust approach to maintaining the integrity of solar pipeline systems.

The approach to connecting solar pipeline joints can hold significant implications for the entire solar system’s effectiveness and lifespan. By rigorously following each step and employing the necessary tools, practitioners can create durable connections that facilitate efficient flow and reduce the chances of future complications. Ensuring compatibility among materials, maintaining precision during alignment, and utilizing high-quality adhesives tailored for solar applications are all pivotal factors. Adapting to environmental conditions and continually educating operators will further elevate the quality of installations. Regular inspections and testing play a vital role in preserving system integrity, and addressing common challenges head-on will only enhance overall effectiveness. Therefore, adherence to a structured and informed method will facilitate the best possible outcomes, solidifying the importance of a robust connection in solar energy systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-pipeline-joint/