1. Connecting solar panel wires and pipes involves several critical steps: ensure proper insulation and safety measures, utilize the correct connectors and tools, establish a clear understanding of the wiring diagram, and periodically perform maintenance checks. The process requires attention to detail in order to optimize efficiency and maintain safety throughout the installation. One of the significant aspects of this undertaking is the emphasis on using appropriate materials and following local regulations, which can significantly impact the performance of the solar energy system. Effective planning and execution can result in a durable and high-performing setup.

1. UNDERSTANDING SOLAR PANEL COMPONENTS

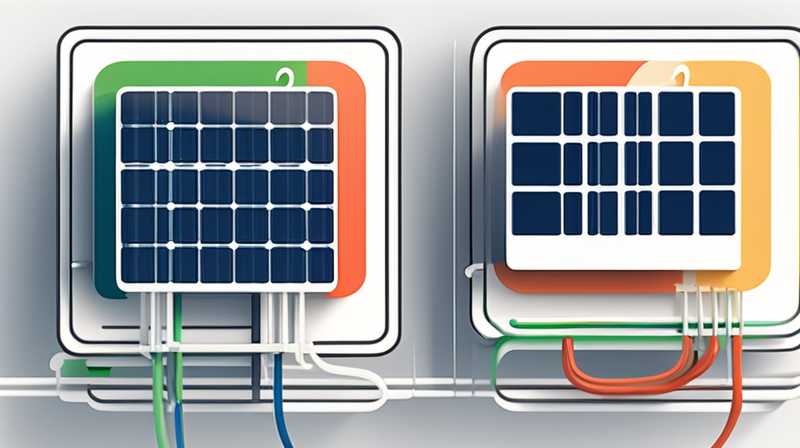

Before embarking on the task of connecting wires and pipes associated with solar panels, it’s crucial to understand the fundamental components that make up a solar energy system. Solar panels themselves are the most visible element, but they work in conjunction with various types of wires, connectors, inverters, and piping systems that play vital roles in energy transmission and storage.

Solar panels operate by converting sunlight into electricity through photovoltaic cells. These cells demand specific wiring configurations to facilitate optimal energy flow. The wires typically used include photovoltaic (PV) wire, which is designed for outdoor usage and can withstand extreme weather conditions. Additionally, connectors such as MC4 connectors are widely used for solar panel installations due to their safety and efficiency in making connections. Employing suboptimal materials or poor connections can lead to significant energy losses and even safety hazards.

Moreover, piping often relates to solar thermal systems, which harness the sun’s energy for heating applications. This system includes pipes responsible for transferring heat from the solar collector to a heating mechanism. Correctly identifying the right type of pipe materials — such as copper or PEX — is essential to ensuring durability and efficiency while performing the intended function. Once a solid understanding of components has been established, it can facilitate a more successful installation process.

2. PREPARING FOR INSTALLATION

Preparation stands out as a pivotal phase in the installation process. Proper planning not only enhances efficiency but also foreshadows potential challenges that may arise during the wiring and piping connections. Start by gathering all essential tools and materials such as wire strippers, electrical tape, connectors, the appropriate gauge wire, and all necessary documentation related to building codes in your locality.

Having the right tools at hand simplifies the entire process and minimizes delays. Ideally, organize tools neatly for quick access while maintaining a clutter-free workspace to ensure safety. Alongside tools, also ensure that you have the correct lengths of wire according to the distance between solar panels and the inverter or battery system. Overestimating wire lengths is often better to prevent any last minute shortages, which can hinder the connection process.

Familiarizing oneself with the wiring diagram is equally paramount. This diagram will serve as a roadmap during the installation. Carefully review wire color codes and connectors to assure that each connection is made precisely, avoiding potential safety hazards or malfunctions. It’s advisable to take notes or mark the plans, making it easier to follow during the installation phase. Proper preparation could considerably decrease the risk of complications during the installation process.

3. STEPS FOR CONNECTING SOLAR PANEL WIRES

When the time for connecting the solar panel wires arrives, attention to detail and adherence to safety protocols are of utmost importance. A systematic approach is key to ensuring that every connection is executed flawlessly.

Initially, ensure that the power supply is completely disconnected prior to beginning any connection. This is a critical safety measure that prevents electrical shocks or short circuits. After ensuring that the system is powered down, proceed by carefully stripping insulation off the wire ends using wire strippers. Proper stripping will expose enough copper to make secure connections without the risk of shorting against other wires or surfaces.

Next, utilize connectors like MC4s to couple the positive and negative wires between your solar panels. These connectors are designed to click into place, providing a tight and secure fit. Applying electrical tape or heat shrink tubing over the connections can furnish additional protection against the elements. Take the time to ensure that connections are not merely functional but also secure, as loose connections can lead to significant energy losses over time. Regularly inspect these connections as part of routine maintenance to verify they remain tight and free from corrosion.

4. INSTALLING THE PIPING SYSTEM

For those integrating a thermal aspect into their solar energy system, the next phase involves the installation of pipes. Similar to wiring, this step requires thorough planning and execution to ensure optimal performance.

The initial task is to determine the routing of the pipes from the solar collectors to the heating storage tank or appliances in need of heat. Careful attention must be paid to the angle and insulation of the pipes, especially if they run outdoors where they might be exposed to extreme temperature variations. Proper placement can help prevent heat loss and maximize the efficiency of the heating system.

When assembling the pipes, make sure to use the appropriate fittings and connectors to prevent leaks. Utilizing Teflon tape on threaded connections can help in achieving an airtight seal. As you progress with the installation, carry out routine checks for leaks by pressurizing the system and inspecting joints cautiously. Maintaining a meticulous approach during this stage guarantees not just immediate functionality, but also longevity of the entire solar thermal system.

5. MAINTAINING YOUR SOLAR PANEL SYSTEM

The journey does not conclude with installation; ongoing maintenance is vital for the sustainability of the solar energy system. Regular inspections can help to identify any potential issues before they escalate into significant problems.

Start by routinely checking both the wiring and piping systems. For wiring, look for any signs of wear, corrosion, or loose connections. In an optimal solar panel system, the connections should remain dry, intact, and well insulated from moisture. If any points show signs of deterioration, timely replacement is advised to maintain a consistent level of efficiency.

Similarly, for the pipes in a solar thermal system, inspect for leaks or corrosion. Regular maintenance checks should include verifying that insulation remains intact, as compromised insulation can result in energy losses. Additionally, flushing the system periodically can prevent the buildup of sediment or debris, ensuring unobstructed flow and efficient heat transfer. Keeping these aspects in check can prolong the lifespan and efficiency of your entire solar energy setup.

FAQS

HOW DO I ENSURE SAFETY WHEN CONNECTING SOLAR PANEL WIRES?

When undertaking the task of connecting solar panel wires, safety must be the foremost priority. To ensure safety, first, disconnect all power sources and verify that no electricity is flowing through the wires. This approach prevents the risk of electrical shock. It is also advisable to use insulated tools and wear protective gear like gloves and goggles to keep yourself shielded from potential hazards. Following local electrical codes and regulations as well as consulting a licensed electrician if necessary can dramatically reduce the likelihood of accidents.

After ensuring safety protocols during installation, periodic inspections are essential to identify any potential wear and tear, particularly corrosion on terminals and connections that might lead to hazards. If you work with photovoltaic systems, understanding ground fault protection methods will further amplify safety measures during both installation and operation.

WHAT TOOLS AND MATERIALS DO I NEED FOR INSTALLATION?

The installation of solar panel wires and pipes requires a comprehensive set of tools and materials tailored to specific needs. The fundamental tools include wire strippers, crimpers, and screwdrivers, while electrical tape or heat shrink tubing is essential for insulation. Additionally, you should have MC4 connectors or any compatible connectors for securely joining wires. Selecting the correct gauge wire suited for your solar panel system is crucial, as it ensures effective conductivity and minimizes losses.

In the case of installing piping for solar thermal systems, you will also need suitable pipe cutters, wrenches, and Teflon tape for securing connections. It’s advantageous to keep a checklist of required materials before beginning the installation, as ensuring that you have everything available reduces the risk of delays and facilitates a smoother installation experience.

HOW OFTEN SHOULD I MAINTAIN MY SOLAR ENERGY SYSTEM?

Proper maintenance of a solar energy system is crucial to sustain efficiency and performance over time. Experts recommend undertaking a comprehensive inspection at least once a year, although more frequent checks may be necessary depending on local environmental factors. Conducting these inspections allows for the identification of any wiring issues, leaks in pipes, or wear on components before they become significantly detrimental.

In addition to annual checks, other recommended maintenance practices include cleaning solar panels to prevent dust and debris accumulation and examining connections for corrosion or looseness throughout the year. Furthermore, conducting a thorough cleaning of the piping system for solar thermal setups is advisable at least once a year to prevent sediment accumulation. Following these maintenance protocols can help prolong the life and efficiency of your solar energy system significantly.

Through proficient planning and meticulous execution, the process of connecting solar panel wires and pipes can lead to a highly efficient solar energy system that promotes sustainability. Comprehensive knowledge of components, thorough preparation, adherence to safety standards, and consistent maintenance practices play crucial roles in achieving an effective installation. Above all, aligning each of these elements can contribute to a seamless integration of solar technology into everyday life. As reliance on renewable energy sources grows, investing effort into optimal installations and regular upkeep is essential. By remaining informed and proactive, individuals can maximize the benefits of their solar energy systems, fostering a greener and more sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-panel-wires-and-pipes/