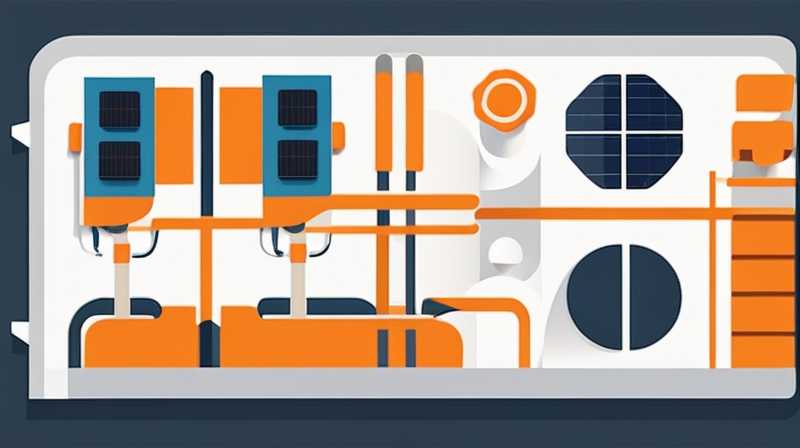

1. TO CONNECT THE SOLAR PANEL PIPES, follow these essential steps: 1) Identify the type of pipes used in your solar heating system and ensure compatibility, 2) Gather necessary tools such as pipe cutters, fittings, and adhesives, 3) Assemble the pipes according to the system design, ensuring that all connections are secure, 4) Test connections for leaks and proper functionality. The second point deserves further elaboration: Compatibility is crucial in solar heating systems because mismatched materials can lead to inefficiencies or system failures. The use of specific materials, such as PEX, copper, or CPVC, ensures durability and longevity. Choosing the correct fittings and connectors helps maintain optimal flow rates and energy transfer, ultimately enhancing the effectiveness of solar energy systems.

2. UNDERSTANDING SOLAR PANEL PIPE CONNECTIONS

The effective connection of solar panel pipes is critical for the successful operation of solar water heating systems. This aspect of solar technology not only influences performance but also affects the overall efficiency and longevity of the entire system. Proper connections help in ensuring the optimal flow of heat transfer fluids, significantly impacting the energy output of the solar array.

Before delving into detailed instructions, it is vital to explore the various types of piping commonly used in solar thermal applications. Among the most prevalent materials are PEX (cross-linked polyethylene), copper, and CPVC (chlorinated polyvinyl chloride), each possessing unique properties that dictate their suitability for specific applications within the solar panel system.

3. TYPES OF SOLAR PIPE MATERIALS

3.1. CROSS-LINKED POLYETHYLENE (PEX)

PEX is favored in modern solar thermal systems due to its flexibility, resistance to corrosion, and adaptability to various temperatures. Its installation is often easier compared to rigid pipes, allowing for efficient routing around obstacles without joints that could potentially lead to leaks. PEX connections typically utilize crimp or clamp fittings, which are reliable when properly installed.

This type of piping also boasts excellent insulation properties, helping to minimize heat loss when transferring solar-heated fluids. However, the longevity of PEX can be compromised by prolonged exposure to sunlight, suggesting that installation should be done with a UV-resistant covering or in shaded areas whenever possible.

3.2. COPPER PIPING

Copper possesses exceptional thermal conductivity, making it an excellent choice for solar applications. Durability is a hallmark characteristic as copper pipes resist corrosion and mechanical stress extremely well. The process of soldering or brazing ensures that connections have an airtight seal, providing strength against pressure fluctuations within the system.

Nevertheless, installation can be more labor-intensive due to the tools required for soldering and bending. Additionally, while copper is highly effective, it can be more cost-prohibitive than other materials, leading to considerations of budget versus longevity in material selection.

3.3. CHLORINATED POLYVINYL CHLORIDE (CPVC)

CPVC serves as a plastic alternative to copper and PEX, and its resistance to high temperatures enhances its utility for hot water systems. Compatible with a variety of adhesives, CPVC joints can be completed with relative speed, allowing for efficient installation. Given its lightweight nature, transport and handling become simplified, which can significantly lower installation labor costs.

On the downside, CPVC requires careful handling during installation since the material can become brittle under extreme temperatures or UV exposure if not properly shielded. Proper insulation should be applied to maintain energy efficiency, maximizing the potential of solar heating technology.

4. ESSENTIAL TOOLS AND MATERIALS

4.1. TOOLS REQUIRED FOR INSTALLATION

The installation of solar panel pipes necessitates the use of specialized tools that ensure precision and reliability. Primary tools include pipe cutters for clean cuts, ensuring no jagged edges that could compromise seals, as well as adjustable wrenches for tight fittings. A heat gun or torch may be required for soldering copper pipes, while crimping tools are essential for PEX installations.

In addition to these tools, measuring devices are critical for identifying the proper lengths and angles of piping. Accurate measurements guarantee that the piping aligns correctly with solar panels, storage tanks, and pumps, facilitating an efficient circulation of fluids throughout the system.

4.2. ADHESIVES AND CONNECTORS

A variety of adhesives and connectors are available to ensure secure and lasting pipe connections. PVC cement is essential for CPVC installations, while solder and flux are required for copper pipes. PEX connections often utilize crimp rings or push-fit connectors, allowing for versatile installation methods that can adapt to different project requirements.

Choosing the right connecting fittings is crucial, as it directly affects the pressure handling and thermal expansion of the system. The selection should be guided by the type of pipe used and the specific demands of the system, ensuring a sturdy and efficient setup.

5. INSTALLATION STEPS FOR SOLAR PANEL PIPES

5.1. PLANNING AND LAYOUT

Before initiating the installation of solar panel pipes, careful planning is paramount. Begin by assessing the installation site to determine optimal layouts, accounting for proximity to energy-generating components such as storage tanks and pumps. Proper planning minimizes pipe runs, substantially reducing potential heat loss involved during fluid movement.

A detailed blueprint ensures that all fittings and materials are acquired ahead of installation, wasting no time in the process. Furthermore, consulting system specifications can highlight the necessary pipe diameters and flow rates, helping to align installations with theoretical performance standards.

5.2. CUTTING AND PREPARING PIPES

Once planning is achieved, cutting pipes to tailored lengths marks the next step. Using a pipe cutter, create clean cuts to ensure a proper fit and seal when connections occur. After cutting, inspect the edges for any burrs, which can lead to leaks; if found, smooth these edges with fine sandpaper or a deburring tool.

Next, prepare the ends of the pipes by cleaning them with a suitable cleaner, ensuring that dust and debris do not interfere with adhesive applications during installation. This step is especially critical for solvent cement-based bonds, as a clean surface ensures optimal adhesion.

5.3. CONNECTING THE PIPES

Depending on the materials chosen, apply the appropriate adhesion method. For CPVC, apply PVC cement liberally to both pipe ends and fitting, rotating them slightly to ensure an even distribution before pressing the pieces together. For copper, solder connections by heating the joint until the metal reaches a melting point, adding solder as necessary.

When working with PEX, insert the ends of the pipes into the fitting and use a crimp or clamp tool to secure them tightly. Ensuring that all connections fit snugly without gaps or spaces minimizes risks of leaks which may further escalate into larger operational issues.

6. TESTING AND MAINTENANCE

6.1. POST-INSTALLATION TESTING

Following the completion of solar panel pipe connections, conducting rigorous testing should be the next priority. This involves examining all connections for leaks and assessing the overall integrity of the installation. Filling the pipes with water under pressure can help identify any weak points in the connections.

Visual inspections can also be beneficial during this phase. Checking for moisture around fittings or signs of drips will provide insight into whether adhesive or soldered connections were successful. Adjustments or repairs should occur swiftly to prevent long-term impact on system performance.

6.2. ROUTINE MAINTENANCE PROCEDURES

Once installation and testing are complete, creating a regimen for routine maintenance is essential for sustaining system performance efficiently. This includes regularly checking all connections and seals, monitoring fluid levels, and ensuring that filter and drain valves are clean and unobstructed.

Additionally, ongoing monitoring of the system’s thermal performance will assist in identifying potential problems early on. By regularly assessing the heat output when the system is operational, any drops in performance can be quickly traced back to faulty connections or inadequate fluid flow, enabling timely corrective measures.

7. FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF USING PEX PIPE FOR SOLAR SYSTEMS?

PEX pipes offer numerous advantages in solar heating applications. Primarily, their flexibility allows for easier installation, especially in complex layouts that may involve corners and curves. This capability reduces the need for numerous fittings that can often be points of failure or increased risk for leaks. Furthermore, PEX is resistant to corrosion and scale buildup, unlike metal piping that might deteriorate over time with consistent exposure to hot water. Additionally, PEX has excellent insulation properties, which minimizes heat loss during fluid transfer. The installation process is typically less demanding, as it does not require specialized tools like soldering equipment, making it accessible for DIY enthusiasts and professional installers alike.

HOW OFTEN SHOULD SOLAR PANEL PIPE CONNECTIONS BE INSPECTED?

Regular inspections of solar panel pipe connections are crucial for maintaining the efficiency and effectiveness of the system. It is generally recommended to conduct a thorough inspection at least once a year, especially after periods of heavy usage or extreme weather conditions. During these checks, one must evaluate all visible connections and joints for any signs of wear, corrosion, or leaks. Additionally, checking for visible moisture around joints can alert to potential issues before they escalate. More frequent evaluations may be necessary in high-demand systems or environments prone to temperature fluctuations. By being proactive with inspections, property owners can address minor issues before they lead to major repairs or loss of efficiency.

WHAT COMMON MISTAKES SHOULD BE AVOIDED DURING INSTALLATION?

Several common pitfalls can compromise the integrity of solar panel pipe installations and should be avoided to ensure optimal performance. Firstly, neglecting to conduct thorough calculations regarding the dimensions and flow rates can lead to inappropriate pipe sizes, which may hinder fluid movement and reduce efficiency. Secondly, failing to clean and prepare pipe ends before applying adhesives or fittings can result in weak seals and increased likelihood of leaks. It is also crucial to not over-tighten fittings, as this can stress pipes and lead to fractures. Lastly, ignoring the importance of regular inspections post-installation compromises the system’s longevity; early detection of wear can prevent larger, costlier repairs down the line.

8. FINAL REMARKS

**Connecting solar panel pipes is an intricate process crucial to the functionality and efficiency of solar heating systems. Employing the correct materials—such as PEX, copper, or CPVC—is essential for ensuring durability and effectiveness. Each type has distinct benefits and drawbacks that should be assessed based on the project’s specific requirements. Choosing the right tools and methodologies is vital for creating solid connections that endure heat and pressure fluctuations. Rigorous testing following installation and routine check-ups are paramount for maintaining optimal performance over the lifespan of the system. By avoiding common mistakes and emphasizing thorough planning, property owners can enjoy the significant benefits afforded by solar energy systems. As technology and products in the renewable energy field progress, familiarizing oneself with the best practices for installations remains imperative. A commitment to sustainable energy usage not only benefits individual households or businesses but also contributes to broader environmental conservation efforts.*

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-panel-pipes-2/