To successfully connect a solar panel after changing the line, it is essential to follow specific steps with precision and caution. 1. Ensure safety, disconnect the solar panel from any power source before starting the wiring process. 2. Review the specifications of both the new line and the solar panel to ensure compatibility. 3. Use appropriate connectors that match the gauge and type of the new wiring. 4. Connect the positive and negative terminals, ensuring you maintain proper polarity to avoid damage. 5. Secure connections properly using electrical tape or heat shrink tubing to prevent any exposure or disconnection. 6. Verify the installation by checking the voltage output with a multimeter before finalizing the setup. Elaborating on the verification process, utilizing a multimeter helps identify any wiring errors that could lead to reduced efficiency or damage to the system. Always refer to the manufacturer’s instructions for specific requirements and recommendations.

1. UNDERSTANDING SOLAR PANEL CONNECTIVITY

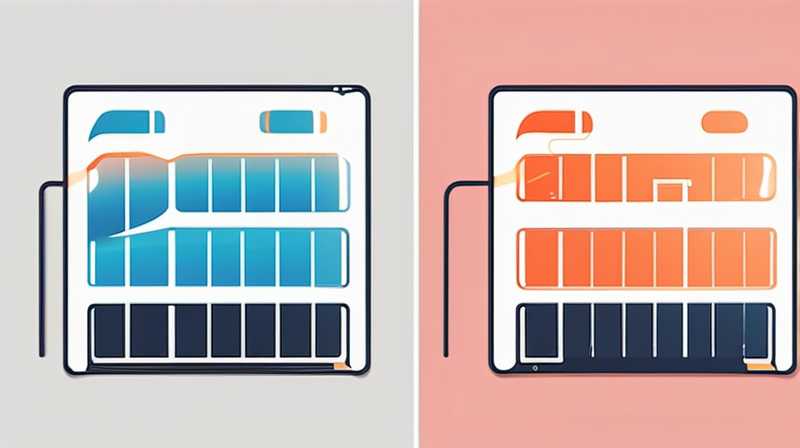

Solar panels function as integral components of photovoltaic systems, transforming sunlight into electrical energy. To truly appreciate the process of connecting solar panels after modifying their wiring, it is crucial to grasp how these systems operate on a fundamental level. When sunlight strikes a solar panel, the photovoltaic cells convert this solar energy into direct current (DC) electricity. This electricity then needs to be routed to the inverter, where it is converted into alternating current (AC) suitable for household use or feeding back into the grid.

Modification of wiring may occur due to a variety of reasons, including wear and tear, damage during installation, or upgrades necessary for increased efficiency. The integrity of connections is paramount, as poor wiring can lead to significant energy losses, safety hazards, and system failures. Understanding the various components, such as cables, connectors, and inverters, helps highlight the delicate nature of solar installations.

2. GATHERING NECESSARY TOOLS AND EQUIPMENT

Before embarking on the wiring process, ensure that all required tools and materials are at hand. This preparation not only facilitates a smoother connection process but also enhances safety compliance. Consider collecting the following items:

- Wire Strippers: Essential for removing insulation from the ends of the wires to enable proper connections.

- Screwdrivers: A variety of sizes can assist in tightening loosened connections specific to terminals found in the panels and inverters.

- Multimeter: This device measures voltage, current, and resistance, allowing for verification of successful connections.

- Electrical Tape or Heat Shrink Tubing: These provide insulation and protection for the connections against external elements.

Understanding the features of these tools enables smoother execution as well as confidence in the safety of the modifications. Equipping oneself with the right tools can make a significant difference in the quality and reliability of the final connection.

3. DISCONNECTING AND PREPARING FOR WIRING

When preparing to connect new wiring to an existing solar panel, safety should be the foremost concern. Start by ensuring the solar panel system is entirely disconnected from any power source. This precaution is essential to safeguard both the installer and the integrity of the solar panel system while making modifications.

Following disconnection, take inventory of the previous wiring setup, noting the arrangement of positive and negative connections as well as any other connections that might be relevant. It is helpful to document these aspects visually or through notes to ensure that the new connections mirror the system’s original configuration. Proper documentation also aids troubleshooting in case any issues arise during the testing phase after installation.

Additionally, inspect the new wiring for quality and compatibility. Ensure that it is rated for the intended application, taking into account voltage and current ratings. Using wires with inappropriate ratings can lead to overheating and potentially catastrophic failures. Investing time in this pertinent detail can lead to a reliable and efficient setup.

4. CONNECTING THE NEW WIRING

Now that the previous wiring has been documented and the new components gathered, the next step is the actual connection process. First, strip the insulation from the ends of the new wires using wire strippers. Ensure that an adequate length is stripped to make secure connections while being cautious not to damage the wire’s conductor itself.

Next, proceed to connect the positive wire from the solar panel to the positive terminal on the inverter or charge controller. It is critical that the positive and negative connections are not swapped; doing so can cause system malfunctions or damage. Connecting the negative wire should follow similarly by establishing a connection to the negative terminal. Using connectors that create a snug fit is advisable, preventing unintentional loosening due to vibrations or environmental stresses.

Following these connections, it is prudent to insulate or cover the connections to protect them against moisture, dirt, or potential physical interference. Employing electrical tape or heat shrink tubing serves this purpose well and ensures longevity.

5. TESTING THE CONNECTIONS

Once all the connections are secured and insulated, the next step is to verify their integrity through testing. Begin by rechecking all connections to confirm that they align correctly with the documented arrangements. Misconfigurations can lead to inefficiencies or hazards.

Utilizing a multimeter, measure the voltage output from the solar panel after re-establishing power to the system. A proper solar panel should output a voltage close to its rated specifications in direct sunlight. If readings are significantly lower, this may indicate an issue with the connections, such as improper polarity or a faulty line.

Document the readings and investigate discrepancies thoroughly as they might reveal underlying issues that necessitate further attention. This stage is crucial; ensuring functionality now prevents larger issues down the line, offering peace of mind that the installation is operational and safe.

6. FINALIZING INSTALLATION AND MAINTENANCE CONSIDERATIONS

With successful testing complete, the installation is nearing its conclusion. Go through each connection once more for a final check before securing any panels or components back into place. Properly organizing and securing loose wires can prevent future accidents or any interference with the system.

Regular maintenance is vital for the sustainability of solar panel functionality. Schedule routine assessments to ensure that all connections remain secure, and that no wear signs are evident on the wiring or components. Environmental factors such as extreme temperatures, heavy winds, or precipitation can affect the longevity of solar systems.

Documentation of maintenance activities can build a historical log that highlights due times for inspections and any developments that may have occurred over the years of the system’s operation. By remaining proactive, issues can often be mitigated or caught early, ensuring efficiency over the long term.

7. ENVIRONMENTAL IMPACTS OF SOLAR ENERGY

Transitioning to solar energy offers profound impacts on environmental conservation efforts. Solar energy generation is devoid of harmful emissions associated with fossil fuel combustion. As such, this form of renewable energy holds the capacity to mitigate climate change. By reducing reliance on non-renewable energy resources, societies move toward sustainable energy pathways.

Moreover, the implementation of solar systems aids in diversification of energy sources. A varied energy portfolio is beneficial not only for reducing dependence on specific energy types but also for stabilizing prices relative to global energy markets. When unconventional sources become a greater portion of energy generation, it reinforces energy security.

On a broader scale, embracing solar energy fosters innovation in technology and infrastructure. Investing in solar technology spurs job creation in manufacturing, installation, and system maintenance. As countries pursue advancements in clean energy, they inherently stimulate economies while simultaneously addressing environmental challenges.

FAQs

WHAT SAFETY MEASURES SHOULD I TAKE WHEN CONNECTING SOLAR PANELS?

When connecting solar panels, maintaining safety is of paramount importance. Begin by turning off the entire system to prevent any active electrical flow. Use insulated tools designed for electrical work to minimize shock risks. Always wear appropriate personal protective equipment (PPE), such as gloves and goggles.

Inspect the working area for hazards, ensuring that it is dry and free of any conductive materials. Familiarize yourself with electrical codes and standards to comply with legal requirements. Having an experienced individual to assist or supervise during the wiring process can also enhance safety, as they provide guidance and assistance in navigating complex connections.

So, prioritize establishing safe practices through the entire process, as neglecting these can lead to serious accidents or failures of the solar panel system.

HOW OFTEN SHOULD SOLAR PANELS BE MAINTAINED?

For optimal performance, solar panels should undergo routine inspections at least once or twice a year. During these assessments, check for any dirt or debris buildup that might obstruct sunlight entry. Environmental conditions, such as high winds or heavy storms, can also impact the structural integrity of the panels and their connections, necessitating additional checks.

Periodically cleaning the panels is essential; using water and a soft cloth helps remove impurities without damaging the surface. Inspect the connections for corrosion or wear, and ensure that all wires remain secured and insulated.

If any issues or abnormalities occur, or if the system performance declines noticeably, addressing these as soon as possible can prevent further complications. Staying on top of maintenance ensures efficiency and effectively extends the operational lifespan of solar panels.

WHAT SHOULD I DO IF I NOTICE A DROP IN PERFORMANCE?

If there is a noticeable drop in performance, several troubleshooting steps can be followed to identify and resolve the issue. Start by inspecting the inverter to check for any error codes or warning lights that may indicate malfunctions or misconfigurations. The inverter serves as a critical component in converting DC from the panels to usable AC.

Next, examine the solar panels themselves. Look for physical obstructions, such as shading from trees or dirt accumulation, obstructing sunlight. Clean the panels if debris is found and observe any changes in performance following cleanup.

If these steps do not yield improvements, consider conducting a thorough review of the entire system’s wiring and connections for any signs of wear or disconnections. Should performance issues persist, contacting a professional for an in-depth diagnosis may be necessary. This diligence can help restore performance and ensure long-term reliability.

Routine checks and maintenance of solar energy systems are critical for their success and reliability. By addressing issues promptly, not only can optimal performance be preserved, but the overall investment value is secured as well. As awareness about energy efficiency improves, connecting solar panel systems can directly impact energy sustainability goals across the globe. The shift to renewable energy is a shared responsibility; staying educated about proper installation and maintenance techniques ensures the effective utilization of these vital resources.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-panel-after-changing-the-line/