1. Understanding Solar Low Pressure Valves: Connecting a solar low pressure valve involves several critical steps to ensure effective functionality in a solar thermal system. 2. Proper Tools and Safety Considerations: Gather necessary tools and take required safety precautions before initiating the installation. 3. System Configuration: Understanding the configuration of your solar setup is vital for correct valve integration. 4. Step-by-Step Installation Guide: Follow a detailed manual for the installation of the valve, ensuring all connections are secure and leak-free. 5. Functional Testing and Troubleshooting: Once installed, conducting tests to verify that the valve operates correctly is essential.

Now, let’s delve deeper into the process of connecting a solar low pressure valve for optimal functionality.

1. UNDERSTANDING SOLAR LOW PRESSURE VALVES

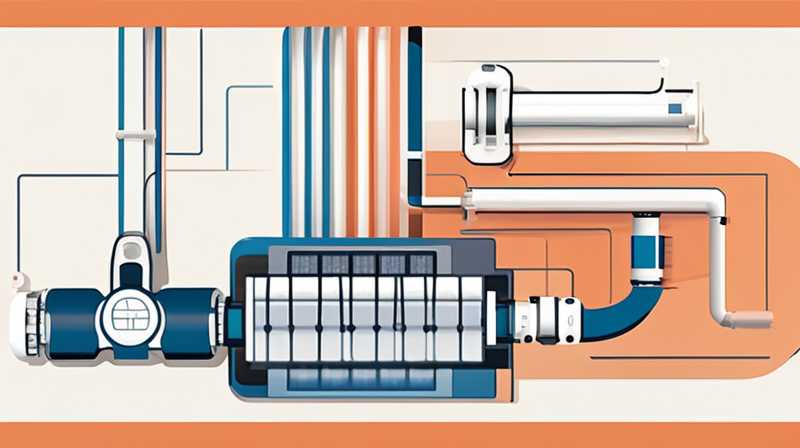

In the realm of solar thermal energy systems, low pressure valves play a fundamental role in maintaining the efficiency and performance of the entire structure. These valves regulate the flow of heat transfer fluids, preventing excessive pressure that can lead to system failures or inefficiencies. It is important to recognize the role that pressure regulation plays in protecting both the solar collectors and the storage tanks.

When the temperature of the heat transfer fluid rises, the risk of pressure build-up increases. A low pressure valve serves as a safety mechanism, allowing excess pressure to escape through a controlled outlet rather than stressing other components of the system. When installing such valves, understanding their design, functionality, and placement is crucial for anyone seeking to optimize their solar heating system’s performance.

With a variety of options available, selecting the appropriate valve hinges on factors such as the make and model of your solar system, the type of heat transfer fluid used, and the specific requirements of your solar thermal application. This knowledge will not only enhance performance but also extend the longevity of your system.

2. PROPER TOOLS AND SAFETY CONSIDERATIONS

Before you embark on the installation of a solar low pressure valve, it is imperative to gather the correct tools. Strategic planning ensures a smooth and efficient process. Tools like adjustable wrenches, pipe cutters, and Teflon tape are essential for creating tight and leak-proof connections. In addition, a multimeter may be useful for checking any electrical components associated with the valve.

Safety precautions are equally essential. Proper personal protective equipment (PPE) can prevent injuries during installation. Gloves, safety goggles, and appropriate clothing should be worn to guard against possible chemical exposures or physical harm. Ensuring that the system is completely depressurized before undertaking installation is critical to avoid accidents; failure to do this can result in hazardous conditions.

Additionally, familiarizing oneself with the specific installation manual for the valve chosen decreases the chance of errors. Recognizing the stipulations for handling heat transfer fluids further improves safety margins.

3. SYSTEM CONFIGURATION

Grasping the overall configuration of your solar thermal system is invaluable in ensuring a successful valve connection. Solar thermal systems can vary significantly in design — from simple setups with a single panel to more elaborate arrays that encompass multiple collectors and storage strategies. Each configuration necessitates a unique installation approach.

Understanding where the low pressure valve fits into this configuration is critical. Most valves are typically installed on the outlet of the solar collector. This location ensures that the valve can effectively monitor the fluid pressure as it exits the collector before it travels toward the storage tank or the heat exchange system. Proper positioning guarantees effective pressure regulation and mitigates risks associated with thermal expansion.

Engaging with the entire system layout helps in grasping how heat transfer fluids circulate. Understanding this flow enables technicians to predict the type and frequency of potential pressure fluctuations, thereby informing the choice and setup of a low pressure valve that can best respond to the unique circumstances presented by your system.

4. STEP-BY-STEP INSTALLATION GUIDE

Once tools are assembled and safety protocols are observed, the next phase involves executing the step-by-step installation of the low pressure valve. Begin by disconnecting the solar thermal system entirely to avoid hazards. Following this, thoroughly assess the area where the valve will be connected; this often requires cleaning debris and any residual fluid present.

The first step in the actual installation involves cutting the piping at the specified location of the valve installation. Using a pipe cutter ensures clean and even cuts, facilitating tight fittings. After preparing the piping, wrap the thread sealing tape around male threads of the valve connections to promote sealing. Following this, attach the valve to the chosen piping section, ensuring it is directed in the correct flow direction indicated on the valve body.

Once installed, prioritize thoroughly tightening all connections to prevent leaks. Next, the system can be repressurized with the heat transfer fluid. Monitor closely for leaks and pressure irregularities during this initial pressurization, correcting any issues immediately.

After installation, verify the intricate functioning of the solar low pressure valve. Conduct tests for performance stability, ensuring that pressure values remain within operational limits as the system heats up and cools down. This validation process is as important as the initial installation, ensuring all components work harmoniously.

FAQs

WHAT TYPE OF SOLAR SYSTEM REQUIRES A LOW PRESSURE VALVE?

Solar thermal systems, particularly those using water or a water-based solution as the heat transfer fluid, typically require low pressure valves. These systems benefit from such valves because they help mitigate risks associated with excessive pressure that can lead to system malfunctions or damage. Low pressure valves are crucial for managing fluid flow and allowing safe release of excess pressure, ensuring the system operates efficiently without overburdening components like collectors and storage tanks.

When utilizing a low pressure valve, it is important to select one that complements the specific requirements of your solar system regarding maximum operating pressures and temperatures. Ultimately, suitable integration of a low pressure valve can foster enhanced durability and performance in a solar thermal system, extending its operational lifespan.

HOW OFTEN SHOULD MAINTENANCE BE CONDUCTED ON THE VALVE?

Maintenance frequency for a solar low pressure valve largely depends on various factors, including system usage, local environmental conditions, and specific characteristics inherent to the system installed. Generally, conducting a thorough inspection annually serves as a prudent practice. During this inspection, technicians should look for signs of wear, leaks, or any performance-related issues.

Additionally, if specific environmental factors are present, such as extreme weather conditions or contamination of the heat transfer fluid, more frequent checks may be warranted. Regular maintenance not only prolongs the life of the valve but also prevents potential safety issues and costly repairs. It is advisable to maintain a comprehensive maintenance log, outlining inspection dates and conditions observed, to ensure the solar thermal system remains in optimal condition.

WHAT ARE THE SIGNS OF A FAULTY LOW PRESSURE VALVE?

Indicators of a malfunctioning low pressure valve often manifest through system performance inconsistencies. Significant variations in pressure readings can signal problems. If the valve fails to release pressure when required, it may lead to excessive pressure build-up within the system, resulting in potential leaks or even catastrophic failure.

Other signs of a faulty valve may include audible hissing or leaking fluid around the valve area. This can indicate a compromised seal or failure to close correctly, leading to continuous fluid loss. Prompt action and evaluation by a qualified technician are crucial when any of these symptoms are observed, preventing further damage and ensuring the solar thermal system operates efficiently.

Together, these inquiries illuminate specific facets of low pressure valve functionality and integration into solar thermal systems.

The significance of efficiently connecting a solar low pressure valve in a solar thermal system cannot be overstated. It employs critical mechanisms, regulating fluid pressure, mitigating risks associated with thermal expansion, and thus protecting underlying components. An understanding of the overall context surrounding this system contributes significantly to ensuring that any installation meets the requirements for efficiency and safety. Putting in place the required tools along with necessary safety measures sets the stage for successful valve integration. Knowing the layout of the entire system facilitates optimal placement of the valve, minimizing any chances of improper functioning. Following a well-defined, step-by-step installation guide helps guarantee precision at each phase, from preparation and connection to testing and validation. Familiarizing oneself with maintenance protocols ensures longevity and performance is sustained over the years. In summary, diligent installation coupled with comprehensive understanding and periodic maintenance enhances the ability of solar thermal systems to convert sunlight into usable heat efficiently and effectively.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-low-pressure-valve/