To properly connect the solar instrument line, multiple steps must be meticulously followed. 1. Identify the components involved in the connection process, 2. Understand wiring requirements, 3. Ensure proper safety measures, 4. Verify system functionality post-connection. A detailed breakdown of each step is crucial to ensure a safe and efficient installation, particularly as solar energy systems continue to gain prominence in sustainable energy solutions. One key aspect to elaborate on is understanding wiring requirements, which involves selecting the appropriate wire gauge and ensuring compatibility with the solar panels, inverters, and batteries. Each of these elements plays an essential role in maintaining optimal system performance, reducing energy loss, and mitigating potential hazards during the installation.

- UNDERSTANDING SOLAR INSTRUMENT LINE COMPONENTS,

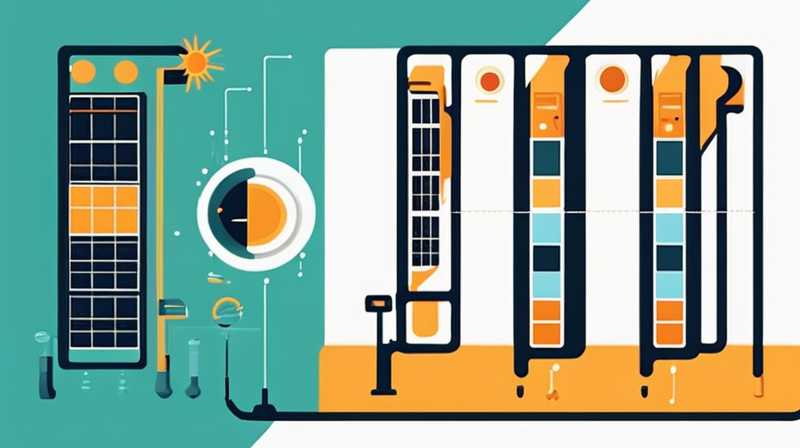

The solar instrument line is a vital aspect of solar energy systems, comprising several essential components that work in cohesion to convert sunlight into usable electricity. Before attempting to connect these instruments, it is crucial to familiarize yourself with each component’s function and interrelationships. Solar panels act as energy collectors, converting solar radiation into direct current (DC) electricity. This electrical output flows through a series of connections to various other components, which include charge controllers, batteries, and inverters.

Charge controllers ensure that the batteries are charged efficiently while preventing overcharging and excessive discharging. This protective measure extends the lifespan of the battery and enhances the overall performance of the solar energy system. Moreover, inverters play a pivotal role in transforming DC electricity produced by the solar panels into alternating current (AC) electricity, which is suitable for home use. It is paramount to understand how these components function independently and collectively to ensure a successful connection and operation.

- DETERMINING WIRING REQUIREMENTS,

Wiring requirements are fundamental in establishing a reliable connection within the solar instrument line. Selecting the correct wire gauge is pivotal, as it directly affects the system’s efficiency and safety. The wire gauge must be suited to carry the maximum current expected during operation without overheating or causing energy loss. Moreover, understanding the distance between components plays a significant role in determining wire size; longer distances may necessitate larger gauge wires to minimize voltage drop.

Documentation of the manufacturer’s specifications provides essential guidance in selecting suitable wiring. Many solar installations now incorporate advanced wiring techniques, such as the use of connectors that allow for easier handling and expansion, accommodating future changes in the system. Additionally, it is wise to use outdoor-rated wiring for any components exposed to the elements, ensuring longevity and resilience against nature’s challenges. Proper wiring ensures not just functionality, but also helps mitigate potential electrical hazards.

- ENSURING SAFETY MEASURES,

Safety measures are paramount when working with solar instrument lines, especially considering the high voltages involved in most installations. Initiating the process with a thorough understanding of electrical safety guidelines is critical. Wearing appropriate personal protective equipment (PPE), such as insulated gloves and safety glasses, should not be overlooked at any stage of the installation.

Disconnecting power sources prior to commencing any work is essential to prevent accidental electric shocks. Moreover, adopting safety protocols during wire connections cannot be emphasized enough. Utilizing insulated tools, including crimpers and wire strippers, reduces the risk of shorts and unintended electrical connections. Conducting a thorough inspection of all wires for frays, gaps, or other potential faults can prevent mishaps during operation. It is vital to prioritize safety to protect not only the individual working on the installation but also the integrity of the entire solar energy system.

- EXECUTING CONNECTION STEPS,

With components identified, wiring requirements determined, and safety measures established, the next phase involves executing the connection steps methodically. Initiating with connecting the solar panels is an ideal starting point. Ensuring correct polarity is crucial. Connecting the positive terminal of one panel to the positive terminal of the next and repeating the process for the negatives establishes a series or parallel connection depending on system design. This arrangement determines the overall voltage and current characteristics of the solar array.

Following panel connections, one should proceed to the charge controller. This device acts as a middleman between the solar panels and the battery system. Establishing these connections necessitates close attention to detail regarding the specifications outlined in both the panel and charge controller manuals. After connections are made, securing each point with appropriate connectors and testing continuity before powering on the system confirms that all connections are solid and safe. Taken together, these steps form the backbone of a properly installed solar instrument line.

- TESTING AND VERIFICATION PROCESS,

Once all connections are made, a testing and verification process serves as a safeguard against potential issues. Utilizing a multimeter, users can check for continuity and proper voltage levels across the system components. Initially, testing the solar panels in sunlight conditions provides insight into the output levels. It is important to note the readings and compare them against the expected values provided by the manufacturer.

After confirming that solar panel outputs meet anticipated metrics, attention should turn to the charge controller and battery connections. Testing the voltage at the battery terminals ensures that charging is taking place as expected. Ensuring each component works harmoniously reinforces system reliability. Finally, conducting a complete system check—which includes verifying the inverter’s performance when connected—ensures that all phases of the solar instrument line function seamlessly together. Implementing these testing steps can prevent future complications, ensuring greater reliability in long-term operations.

- MAINTENANCE CONSIDERATIONS AND LONG-TERM PERFORMANCE,

Once set up, ongoing maintenance is vital to uphold the performance and longevity of a solar energy system. The initial steps may establish a foundation, yet regular inspections and upkeep can catch potential problems early. One of the most straightforward forms of maintenance involves keeping the solar panels clean. Accumulation of debris, dirt, or snow can inhibit light absorption, reducing energy generation potential.

Periodic inspections of electrical connections are equally important. Verifying that screws and connectors remain tight can prevent energy loss and electrical arcing risks. It is beneficial to develop a maintenance schedule following manufacturer recommendations, which often detail inspection frequency and recommended checks. Emphasizing these preventative measures ensures that the solar instrument line functions efficiently for years to come. Paying attention to these critical factors fosters a robust, sustainable energy source.

- THE ROLE OF TECHNOLOGY IN MODERN SOLAR CONNECTIONS,

Technological advancements greatly influence contemporary practices regarding solar connections. With the advent of smart monitoring systems, users can now monitor their solar system’s performance in real-time. These systems alert users regarding potential issues, allowing for timely interventions that can prevent larger problems. Cloud-based solutions enable users to access data remotely, providing opportunities for better-informed decisions regarding energy consumption and maintenance.

Furthermore, advancements in wiring technology, like plug-and-play systems, simplify installations. This innovation reduces the complexity of connections while boosting efficiency and safety. Emerging battery technologies, such as lithium-ion batteries, require unique considerations during connection processes but offer substantial benefits in terms of energy density and lifespan. Integrating these cutting-edge advancements leads toward a smarter approach to solar energy management, maximizing efficiency and sustainability.

COMMON QUESTIONS

- IS SPECIALIZED TRAINING REQUIRED FOR CONNECTING SOLAR INSTRUMENT LINES?

While basic electrical knowledge may suffice for simple installations, specialized training significantly enhances installation and connection accuracy. Many solar energy systems harnessing high voltages necessitate a solid understanding of electrical principles and safety protocols. Various organizations offer certification programs that cover the pivotal aspects of solar energy systems, including wiring, safety standards, and troubleshooting techniques. These programs furnish installers with the essential expertise to handle diverse scenarios, ensuring that connections are made securely and efficiently. Additional areas of study may include renewable energy legislation and local codes that govern solar installations. Known as the National Electrical Code (NEC) in the United States, these guidelines often detail specific requirements that influence safety and installation practices. Ultimately, while it is possible to undertake connections without formal training, pursuing education in the field mitigates risks and enhances knowledge regarding effective and compliant installations. - WHAT ARE PLUG-AND-PLAY CONNECTIONS AND HOW DO THEY WORK?

Plug-and-play connections refer to a modern approach in solar energy systems that simplifies installation and connectivity. These systems utilize pre-fabricated components complete with integrated connectors that facilitate seamless integration into existing solar setups. Users can connect panels, inverters, and batteries with minimal effort, significantly reducing installation time and complexity. The conventional approach often involved intricate wiring schemes requiring significant time and skill to ensure everything was connected safely and accurately. Plug-and-play systems minimize this burden—from component selection to actual assembly—allowing users with less technical expertise to engage effectively in solar installations. However, even with their ease of use, it remains crucial to understand specifications and safety considerations. These advantages make plug-and-play connections an increasingly popular choice among both professional installers and DIY enthusiasts, particularly as solar adoption and demand continue to rise. -

CAN SOLAR INSTRUMENT LINES BE CONNECTED WITHOUT PROFESSIONAL HELP?

Connecting solar instrument lines independently is feasible for individuals with basic electrical knowledge. Many homeowners successfully undertake this journey, relying on the wealth of resources available, including manuals, online tutorials, and community forums. However, caution is advised, especially when working with high-voltage systems. Familiarity with wiring standards and safety protocols is imperative to ensure accurate connections and prevent damage or injury. Many recommend starting with small-scale, simpler systems before tackling larger installations, allowing burgeoning installers to build confidence and skill gradually. For those unsure or lacking experience, enlisting a professional is prudent. Professionals often have extensive experience in navigating complexities related to regulations, ensuring compliance, and optimizing system functionality. Ultimately, the decision to connect solar instrument lines independently or with professional guidance depends on individual comfort levels and expertise regarding the complexities involved.

Establishing a well-connected solar instrument line is crucial for ensuring the efficiency and longevity of a solar energy system. Thorough understanding and adherence to wiring standards, safety practices, and maintenance protocols culminate in a successful setup. Each connection plays an integral role in converting solar energy into usable electricity, impacting overall functionality and performance. Technological advancements and reduced complexity, such as plug-and-play options, have streamlined the connection process significantly compared to traditional methods. Furthermore, routine maintenance and systematic checks add layers of security and reliability to the solar setup, enabling it to serve energy needs sustainably over the long term. Engaging in continuous education about the latest techniques and tools can also enhance operational efficiency. Individuals should weigh their expertise, knowledge, and comfort level with electrical systems when deciding whether to undertake installations themselves or seek professional assistance. Ultimately, a well-executed connection process opens the door to harnessing solar energy effectively, contributing positively to environmental conservation and energy independence in an ever-evolving world.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-instrument-line/