To connect a solar display panel circuit, follow these steps: 1. Understand necessary components, wires, and connections; 2. Ensure safety precautions are observed to avoid hazards; 3. Follow a systematic approach to assemble the circuit; 4. Test the output and functionality of the system.

1. ESSENTIAL COMPONENTS AND WIRING

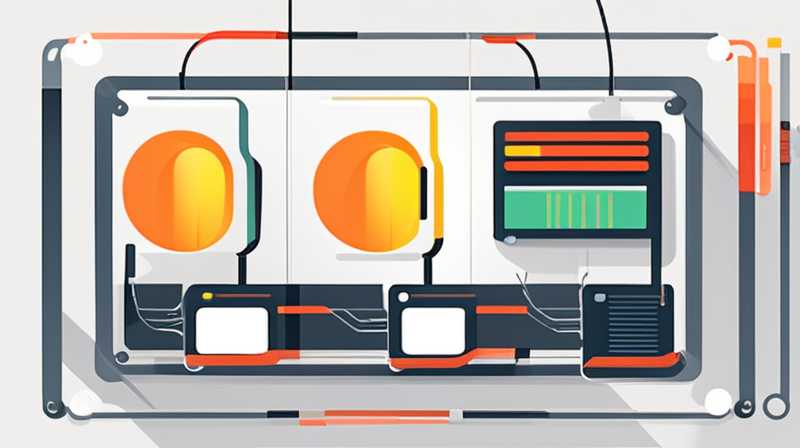

In any solar display panel circuit setup, a clear understanding of the required components is fundamental. Essential items typically include photovoltaic panels that capture sunlight, a charge controller to regulate voltage, a storage battery to store energy, and an inverter that converts direct current (DC) into alternating current (AC) for household usage. Each component plays a critical role in ensuring the efficiency and longevity of the solar power system.

When wiring the circuit, it is also crucial to select the appropriate gauge of wire. The wire gauge should correspond to the voltage and current ratings of the components to prevent overheating and energy loss. Copper wire is often preferred due to its excellent conductivity. Appropriate connections and junctions must be made to ensure a seamless flow of electricity throughout the system. Using quality connectors can minimize resistive losses and enhance the system’s reliability.

2. SAFETY CONSIDERATIONS

Prioritizing safety cannot be overstated in any electrical setup, particularly one that utilizes solar energy. Personal protective equipment (PPE) should be worn throughout the assembly process. This includes gloves and safety goggles, which protect from potential electrical hazards and physical harm when handling components.

Electrical systems inherently pose hazards, such as shocks or short circuits. Therefore, ensuring all connections are secure and that components are rated for the specific loads encountered in the system is paramount. Before starting work on the circuit, it is advisable to disconnect power sources and use insulated tools. If uncertain about any procedures, consulting with a licensed electrician can provide additional guidance and reassurance.

3. CIRCUIT ASSEMBLY PROCESS

Commence by positioning the solar panels in a location that receives optimal sunlight throughout the day, preferably at a tilt to enhance exposure. Then, make the necessary electrical connections. Connect the panels’ positive terminals to the charge controller’s positive terminal and the negative terminals likewise. This direct connection enables the harvested energy from sunlight to flow into the controller, which regulates the voltage before directing it to the battery for storage.

Once set up, proceed to connect the charge controller to the battery. Ensure that the connections maintain polarity to prevent damage. The correct configuration will result in the controller managing the charge flow, preventing overcharging, and increasing battery longevity. Following this, connecting the inverter to the battery allows for utilizing stored energy in the form of AC power. At this stage, perform thorough inspections of all connections to eliminate loose wires or potential faults.

4. TESTING AND VERIFICATION

With the connections completed, it becomes critical to verify the system’s functionality. First, check the output from the solar panels during sunlight hours to ascertain the voltage and current levels generated. Utilize a multimeter to measure these values accurately. It is vital to confirm that values align with specifications to affirm that the panels operate effectively.

Following verification of the solar panels, test the charge controller and battery. Monitor the battery voltage to ensure that it is receiving a proper charge. This process entails ensuring that the controller displays an appropriate charge status. Finally, the inverter can be tested by connecting a small appliance to ensure that the AC output functions correctly. By following these testing procedures, one ensures that the entire system operates optimally.

FAQs

WHAT TYPE OF SOLAR PANEL IS BEST FOR A DISPLAY?

The best solar panel for a display largely depends on several factors, including the size of the display and power requirements. Monocrystalline solar panels are often preferred due to their higher efficiency and aesthetic appeal. They have a better space-to-output ratio, making them suitable for smaller installations where space is a concern. Unfortunately, they tend to be more expensive. On the other hand, polycrystalline panels are more budget-friendly but slightly less efficient.

When selecting a solar panel, consider not only efficiency but also durability and manufacturer reputation. Panels with a robust warranty (typically around 25 years) can provide assurance of long-term performance. Additionally, assess environmental factors, such as average sunlight availability in your geographical location. Understanding your specific energy consumption needs will guide you in choosing the most appropriate solar panel type for your display.

HOW DO I CHOOSE THE RIGHT CHARGE CONTROLLER?

Selecting an appropriate charge controller is fundamental for the longevity and efficiency of your solar display panel circuit. Two main types of controllers exist: Pulse Width Modulation (PWM) and Maximum Power Point Tracking (MPPT). The latter is generally more efficient, especially in larger systems, as it optimizes the power output from the solar panels.

The first step in choosing a controller involves assessing the total amperage from the solar panels and matching it with the controller’s rating. It is advisable to choose a controller that exceeds your system’s capacity to handle surges without issues. Additionally, look for features like temperature compensation and adjustable settings, which can afford better battery management. An ideal controller will ensure your power system operates efficiently while prolonging battery life.

WHAT MAINTENANCE IS REQUIRED FOR A SOLAR DISPLAY PANEL SYSTEM?

Maintaining a solar display panel system involves several activities aimed at ensuring efficient operation and extending its lifespan. Periodic cleaning of solar panels is critical; dirt and debris can significantly reduce efficiency. Clean the panels with a soft cloth or sponge and a mixture of water with a mild detergent without using abrasive materials that may scratch the surface.

In addition to cleaning, regular inspections of wiring and connections allow for early detection of wear, corrosion, or damage. Inspect the charge controller settings annually to confirm they are optimized for the current solar panel configuration. It is advisable to check the battery periodically for signs of swelling or leakage, indicating potential failure. By adhering to maintenance best practices, one can enjoy the benefits of renewable energy for many years.

The utilization of solar display panels promotes sustainable energy consumption, which is imperative in today’s environmentally conscious society. Embracing the solar energy revolution requires both a foundational understanding of the components and a thorough approach to installation and maintenance. By taking the time to connect solar display panel circuits with precision and caution, individuals can greatly contribute to reducing reliance on fossil fuels. This shift not only helps in conserving energy but also plays an essential role in decreasing greenhouse gas emissions. Understanding the importance of this energy system, coupled with adhering to safety guidelines, leads to successful implementation. Further, engaging in regular inspections and performing necessary maintenance will ensure the system functions optimally over its lifespan. Ultimately, investing time in learning about and executing these practices results in a reliable power source from an abundant resource, paving the way for a greener future. By sharing knowledge on connecting solar display panel circuits, communities can become more empowered, promoting sustainable practices widely.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-display-panel-circuit/