In order to connect the solar display circuit effectively, one must adhere to a structured approach involving multiple components, 1. Understanding the components, 2. Following wiring schematics for precision, 3. Ensuring safety during installation, 4. Testing the connection methodically. Each step is crucial to ensure that the solar display circuit functions optimally and provides accurate readings or displays.

1. UNDERSTANDING THE COMPONENTS

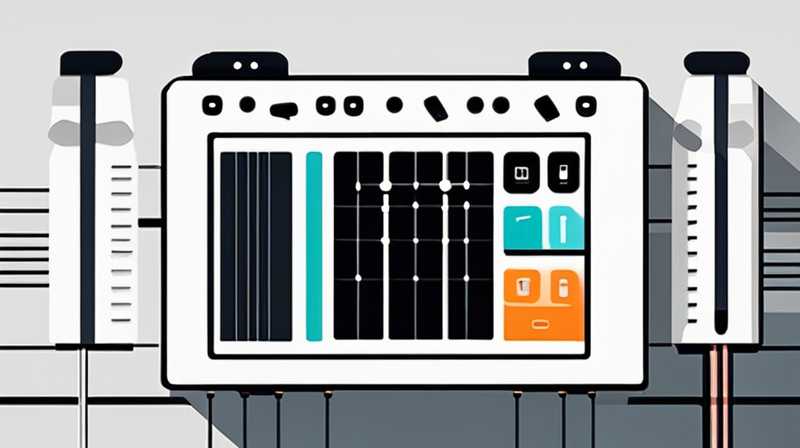

A comprehensive grasp of the components involved in the solar display circuit is of utmost importance. These elements come together to create a system that converts solar energy into usable electrical energy, which is then displayed or measured. The primary components typically found in such circuits include solar panels, a charge controller, batteries, display units, and connecting wires.

Solar panels, or photovoltaic cells, are responsible for capturing sunlight and converting it into electricity. They generate direct current (DC) electricity from sunlight, which can then be used immediately or stored for later use. Charge controllers play a crucial role in voltage regulation, preventing overcharging of batteries and ensuring a smooth power transfer. Batteries store the generated energy and provide a reliable power source when sunlight is insufficient. Finally, display units provide visual representation of power generation or stored energy levels.

Understanding the function and specification of each component allows for an informed selection process, ensuring compatibility and optimal performance within the circuit design.

2. FOLLOWING WIRING SCHEMATICS FOR PRECISION

Once the components of the solar display circuit have been identified, the next logical step involves adhering to detailed wiring schematics. Proper wiring is paramount in ensuring that each element interacts effectively without malfunctioning. Numerous online resources and manuals offer diagrams and instructions that can facilitate this task.

The wiring process generally begins with connecting the solar panel to the charge controller. Using appropriate gauge wire is vital to minimize power loss through resistance. Moreover, ensuring correct polarity is crucial; connecting positive to positive and negative to negative prevents damage to the entire circuit. Next, the charge controller should be connected to the battery, allowing for efficient charging and power management. Lastly, the display unit must be wired to read battery levels or generation data accurately. Ensuring that each connection is secure and insulated is also essential to prevent any accidental short circuits.

Proper attention to wiring schematics ensures the circuit functions correctly, allowing each component to serve its purpose without interference from faulty connections.

3. ENSURING SAFETY DURING INSTALLATION

With various electrical components being handled, the significance of safety during installation cannot be overstated. Awareness and adherence to safety protocols can prevent accidents, injuries, or equipment damage. Begin by wearing safety gear, such as gloves and goggles, when dealing with electrical circuits. This protective measure is crucial as it guards against accidental shocks or electrical burns.

Before starting the installation, inspect the components and ensure that they are free from defects or damage. Disconnecting all components from the power source while wiring is also essential to ensure safety. Adequate measures such as using insulated tools can prevent electrical shock during the installation process.

Maintaining a clean workstation and organizing tools will help minimize the chances of accidents. Once all connections have been made, a thorough inspection is imperative to confirm that everything is in order prior to energizing the circuit.

4. TESTING THE CONNECTION METHODICALLY

Upon completing the installation of the solar display circuit, conducting a meticulous test is the next step. This verification process ensures all components function as anticipated and that the connections are secure. Start by connecting the solar panel to sunlight and observe whether the charge controller displays relevant information regarding input.

Following this initial test, check the voltage output from the solar panel and the battery using a multimeter. It is essential to validate that voltage readings are within the expected ranges for the specific components used in the circuit. After confirming that the solar panel is working correctly, examine the connections between the charge controller and the battery. Observing any discrepancies at this stage can prevent further complications later on.

Lastly, verify the functionality of the display unit. This includes checking whether it correctly indicates battery levels or solar generation data. Testing all components ensures the system operates optimally, thereby highlighting any required adjustments or repairs.

FREQUENTLY ASKED QUESTIONS

WHAT TYPE OF SOLAR PANEL IS BEST FOR A DISPLAY CIRCUIT?

Choosing the right solar panel for a display circuit depends on several factors. 1. Wattage is a primary consideration; it should match the requirements of the entire circuit to ensure sufficient power generation. Generally, a panel rated between 50 to 100 watts is suitable for small display systems, while larger applications may require panels with higher wattage ratings. 2. Efficiency also plays a significant role; monocrystalline panels usually provide higher efficiency compared to polycrystalline ones, making them more suitable for compact spaces. 3. Durability and weather resistance are also essential, especially if the installation is outdoors.

Ensuring proper mounting systems and tilt angles is another critical element that can enhance the performance of solar panels in connectivity with display circuits. Furthermore, you might want to consider whether the panel can withstand local climatic conditions. Researching manufacturer ratings and performance in similar installations can guide the decision-making process.

HOW DO I TROUBLESHOOT A NON-FUNCTIONING SOLAR DISPLAY CIRCUIT?

Addressing issues in a non-functioning solar display circuit requires systematic troubleshooting. The first step involves checking connections for security and integrity. Loose or corroded connections can lead to power loss or prevent the circuit from operating altogether. Next, inspect the solar panel; look for physical damage or dirt accumulation that may hinder performance. Regular maintenance is crucial, as grime can obstruct sunlight exposure.

If the solar panel and connections appear intact, use a multimeter to test both the output of the solar panel and the battery voltage. Measuring the charge controller’s functionality is also advisable. Verifying if it correctly regulates the current and voltage will help identify any faults. If, after all these checks, the system still does not work, consulting the user manual or contacting a professional can provide further insights and assistance.

WHAT SAFETY PRECAUTIONS SHOULD I TAKE WHEN WORKING WITH A SOLAR DISPLAY CIRCUIT?

Prioritizing safety while working with solar display circuits is essential. 1. Always wear protective gear, such as gloves and goggles, to minimize risks of electric shocks or injuries while handling electrical components. 2. Ensure that the work area is dry and well-lit to reduce the risk of accidental falls or missteps. 3. Disconnect all components from any power source before starting the wiring process can prevent shock and damage to equipment. Utilizing insulated tools during the installation process also reduces the risk of electrical shocks.

Lastly, establish clear procedures for handling tools and equipment. Properly labeling wires and components can eliminate confusion, ensuring a smooth installation process while simultaneously enhancing safety. Keeping a fire extinguisher nearby, although seldom required, can also be a precautionary measure when working with electrical systems, particularly during the testing phase.

When it comes to connecting the solar display circuit, crucial aspects include understanding components, adhering to wiring protocols, ensuring safety, and conducting thorough testing. Mastery of each of these elements allows for a seamless integration of the circuit while maximizing efficiency and effectiveness. Doing so not only leads to optimal performance but also enhances user satisfaction while minimizing potential hazards.

A profound understanding of the components clarifies their roles, thereby leading to informed choices on compatible products. Consequently, meticulous attention to wiring schematics prevents power loss and operational failures. Additionally, safety precautions are indispensable in protecting individuals and equipment alike. Engaging in systematic testing helps ensure that each element of the circuit functions harmoniously.

Through a structured approach to connecting the solar display circuit, users can establish reliable systems for energy capture and display. Such systems not only foster an appreciation for renewable energy but also empower individuals to harness the sun’s abundant resources effectively. By executing these operations with professionalism and precision, one can create a functional and efficient solar display circuit that contributes positively to energy management and sustainability efforts.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-display-circuit/