In today’s world, establishing a connection for the solar control assembly is crucial for enhancing energy efficiency. 1. Understand the components involved, 2. Follow the manufacturer’s guidelines, 3. Ensure proper wiring connections, 4. Test the system after installation. Understanding these aspects will not only streamline the assembly process but also contribute to the functionality and longevity of the solar system. Focusing on understanding all components, for instance, allows installers to recognize each part’s specific role and importance, ensuring they are adequately addressed during the connection process.

1. UNDERSTANDING THE SOLAR CONTROL ASSEMBLY

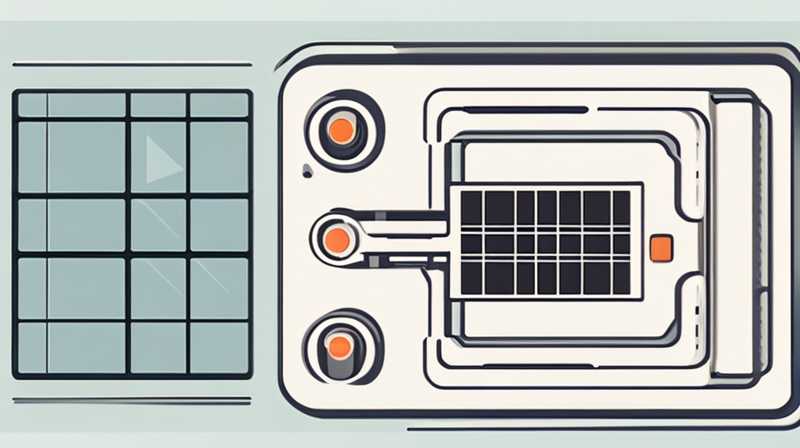

The solar control assembly represents a pivotal aspect of solar energy systems, orchestrating how power generated from photovoltaic panels is utilized. At its core, this configuration typically comprises essential components such as a solar inverter, charge controller, and sometimes, a monitoring system that tracks energy production and usage. Defined roles within the assembly ensure the efficient conversion of sunlight into usable energy.

The solar inverter is especially important within the assembly; it converts direct current (DC) produced by solar panels into alternating current (AC), which is utilized by most household appliances. A charge controller, on the other hand, regulates battery charging, preventing overcharging or discharging, thus maximizing battery lifespan. Understanding each component’s function is paramount, as this knowledge contributes significantly to the efficacy of solar energy systems. Proper interaction among these components guarantees not only seamless operation but also optimal energy harvest.

2. COMPONENTS REQUIRED FOR CONNECTION

Before proceeding with the connection process, it is vital to gather all necessary components. Typically, required items include solar panels, an inverter, a charge controller, wiring, and safety equipment such as fuses or breakers. Each of these components plays a distinct role in the solar energy system, and having them prepared beforehand ensures a smoother installation process.

The wiring is essential for creating connections among these components. It must be appropriately rated for the voltage and amperage of the system to avoid overheating or potential failure. Additionally, it is advisable to incorporate safety equipment, such as fuses, to protect the system from unforeseen electrical faults. Using equipment that meets industry standards not only enhances safety but can also improve overall energy system performance.

3. PREPARING FOR INSTALLATION

Preparation is key before undertaking the assembly connection. This involves reading all manufacturer instructions thoroughly, as they contain critical information unique to specific products. Understanding installation sequences and connection diagrams can help avoid common pitfalls that may arise from misinterpretation or oversight. Familiarizing oneself with all components heightens the chance of making effective connections.

Moreover, assessing the installation location is essential. Factors such as sunlight exposure, roof orientation, and shading from nearby trees or buildings should be analyzed beforehand. Ensuring a clear line of sight for solar panels maximizes efficiency and energy production, so assessing these aspects can lead to making necessary adjustments to the installation layout.

Prior to starting, having an organized workspace can prevent unnecessary complications during the assembly process. Keeping tools and components accessible facilitates a smoother workflow while maintaining focus on the task at hand.

4. EXECUTING THE CONNECTION

When ready, commence the assembly connections, starting with solar panels. Ensure that panels are securely mounted before connecting them to the charge controller or inverter. Depending on the connection type—series or parallel—be vigilant about voltage and current specifications, as improper configurations can adversely affect system performance.

In a series connection, solar panels increase the total voltage while maintaining the same current, whereas a parallel configuration increases current while maintaining voltage levels. Understanding these electrical relationships is crucial; employing the right configuration helps to achieve desired system output and ensures more reliable operation over time.

Following panel connections, proceed to wire the charge controller. The charge controller should be linked directly to the battery and solar panels. Properly observing polarity while making these connections is essential to avoid reverse polarity issues that can damage components. After the charge controller connection, attach the inverter to the charge controller and ensure wiring follows the labelled input/output specifications.

5. TESTING THE SYSTEM FUNCTIONALITY

After completing the connections, a series of tests are necessary to confirm the system’s functionality. It’s imperative to check for any loose connections or wiring issues before powering the system. Utilizing a multimeter can aid in measuring voltage levels across different components to ensure that they meet specified operational parameters.

Moreover, monitoring the initial performance of the solar system can provide insight into any necessary adjustments. Observing whether the inverter registers output can offer confirmation that energy is being correctly converted and utilized. Regular checks not only promote system integrity but also enhance efficiency by addressing issues early.

6. MAINTAINING YOUR SOLAR CONTROL ASSEMBLY

Once connected and operational, regular maintenance of the solar control assembly is essential for sustaining efficiency and prolonging the lifespan of the system. Periodic inspections should involve checking wiring integrity, ensuring that connections remain secure, and analyzing component performance.

Cleaning solar panels regularly is also a good practice to maintain energy absorption rates. Debris, dust, or leaves can obstruct sunlight exposure, leading to decreased energy production. Keeping panels clean, inspecting the charge controller, and confirming the inverter functions correctly contribute significantly to a solar system’s longevity and performance.

Additionally, staying informed about advancements in solar technology can lead to system upgrades over time, enhancing energy efficiency and reliability. Keeping abreast of changing technologies and best practices helps refine the overall system performance in the long run.

FREQUENTLY ASKED QUESTIONS

HOW DO I IDENTIFY A MALFUNCTIONING SOLAR CONTROL ASSEMBLY?

Recognizing issues within a solar control assembly often begins with observing discrepancies in power output. Checking the inverter display can reveal error codes indicating connection problems or malfunctions. Additionally, if energy bills seem unexpectedly high, troubleshooting the system for inefficiencies becomes imperative.

Regular maintenance routines contribute to identifying potential issues early on. Inspecting wiring for damage and ensuring component security can uncover hidden problems. Moreover, monitoring software attached to modern systems can provide real-time data on energy usage and production, offering clues to underlying issues.

If problems persist, consulting a professional installer or technician with expertise in solar energy systems is advisable. Their experience may lead to more efficient troubleshooting and solutions that enhance system performance.

WHAT SAFETY MEASURES SHOULD I TAKE WHEN CONNECTING SOLAR EQUIPMENT?

Prior to beginning the installation and connection of any solar equipment, implementing various safety measures is crucial to ensure personal and equipment safety. First, wearing protective gear, such as gloves and safety glasses, can shield against potential hazards like electric shock or falling debris.

Detailed knowledge of electrical systems is necessary; if uncertain, consulting professional installers ensures safety protocols are effectively followed. Utilizing insulated tools can prevent inadvertent contact with live wires. Moreover, shutting off all electric connections before beginning work will mitigate risks during installation.

Staying organized and maintaining a tidy workspace also contributes to safety. By managing tools and components effectively, risks of trips, falls, or other accidents diminish. If working at elevated heights, employing safety harnesses and securing ladders will further enhance safety during the assembly process.

CAN I INSTALL A SOLAR CONTROL ASSEMBLY MYSELF?

While it is possible for individuals with technical skills to install a solar control assembly independently, seeking expert assistance is often advisable. The complexity of solar energy systems and the importance of correct installation for optimal performance merit careful evaluation of one’s capabilities.

Understanding local regulations, permits, and grid connection requirements can pose challenges to DIY installations. Moreover, improper connections or configurations can lead to decreased efficiency and even dangerous malfunctions. Investing in professional installation often provides assurance that the system will operate effectively from the outset.

For those interested in hands-on installation, thorough research and possibly educational courses can provide substantial guidance. Engaging with community resources or seeking mentorship from experienced practitioners can also bolster confidence and knowledge before tackling such an impactful project.

In wrapping up this extensive discussion regarding the connection of a solar control assembly, it is highlighted that a systematic approach underlines the entire process. Each phase—from comprehending the fundamental components to executing precise connections and ensuring effective testing—is vital. Grasping the roles of each element within the solar system not only clarifies the assembly process but also emphasizes the importance of safety, maintenance, and local regulations. Utilizing professional expertise where uncertainty arises can safeguard personal security and enhance overall system performance. By implementing sound methods, individuals can optimize their solar energy systems, contributing to efficient energy use while minimizing environmental impact. Investing time and resources into a well-connected solar control assembly will ultimately yield long-term benefits, marking a significant stride towards sustainable living. Beyond energy generation, the act of connecting these components is a vital step toward broader ecological responsibility and energy independence—both pivotal in today’s energy landscape.**

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-control-assembly/