To connect a solar aluminum-plastic pipe four-way, follow these essential steps: 1. Gather necessary tools and materials, 2. Ensure all components fit properly, 3. Prepare the pipes by cutting them to appropriate lengths, 4. Connect each pipe section to the four-way fitting securely. The process requires attention to detail, particularly the fitting integrity to avoid leaks.

1. TOOLS AND MATERIALS REQUIRED

Acquiring the correct instruments and materials is crucial before embarking on this connection task. The essential tools typically encompass a pipe cutter, a measuring tape, a deburring tool, and possibly a heat gun. Selecting the appropriate fittings and the solar aluminum-plastic pipe is equally important; ensure all components are compatible. This step guarantees that all materials can withstand the pressure and temperature variations they may encounter within a solar heating system.

It is vital to assess the space where the four-way fitting will be installed. Adequate room for maneuvering is necessary to execute precise cuts and join fittings. If the workspace is cramped, consider using smaller tools to navigate around awkward angles. Ultimately, having everything organized and within reach minimizes interruptions and streamlines the connection process.

2. UNDERSTANDING THE PIPE STRUCTURE

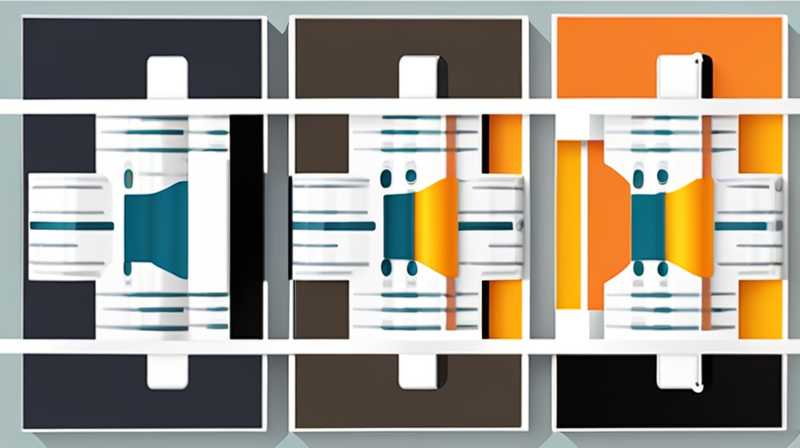

A fundamental aspect of successful piping involves comprehending the unique characteristics of solar aluminum-plastic pipes. These pipes consist of a layer of aluminum sandwiched between two layers of plastic, creating a strong yet lightweight product. This structure offers superior corrosion resistance and flexibility compared to conventional plumbing materials.

Moreover, understanding the intended use of these pipes in solar heating systems highlights their advantages. The aluminum layer ensures excellent thermal conductivity, facilitating efficient heat transfer from solar collectors to storage tanks. Properly connecting these pipes is crucial for ensuring the longevity and performance of the system, as improper fittings can lead to significant losses in efficiency due to leaks or blockage.

3. PIPE CUTTING TECHNIQUES

Prior to connecting the four-way fitting, precise cutting of aluminum-plastic pipes is imperative. Begin by measuring the required lengths carefully, taking into account any angles and fixture positions. Precision in measurement directly impacts the aligning of the pipes and the effectiveness of the connection.

Employ a pipe cutter to achieve a smooth, clean cut. A jagged or uneven cut can lead to difficulties during installation, compromising the sealing ability of fittings. Using a deburring tool afterward ensures that no sharp edges are left, preventing injury and allowing for a better fit during connections. This careful preparation sets the stage for a seamless integration of the piping system.

4. PREPARING FOR CONNECTION

Before proceeding to make the connections, confirm that all surfaces are clean and free from debris. The presence of dirt or grime can impede the seals formed by joints and fittings, leading to future leaks or inefficiencies within the system.

If necessary, use a compatible cleaning solution to wipe down the areas that will be connected. Ensuring everything is dry before commencing with the assembly is also critical. Moisture can hinder adhesive properties, especially if using solvent cements or other bonding agents. Preparation at this stage is vital, as it protects the integrity of the entire piping system during its service life.

5. CONNECTING THE FOUR-WAY FITTING

With preparation complete, connect the four-way fitting to the existing pipe sections. Begin by inserting the end of one pipe into one of the four openings of the fitting, ensuring a tight fit. If applicable, use a heat gun to slightly warm the fitting and pipe ends; this can encourage a better bonding process.

Secure the connection with appropriate fasteners. Various options may be available, including clamps or adhesive, depending on the specific design of the fitting. It is paramount to check that the pipe remains straight and flush against the fitting to prevent stress at the joint. Repeat this process for each pipe section connecting to the four-way fitting. Ensuring that all connections are made firmly is essential for the overall functionality of the solar heating system.

6. TESTING FOR LEAKS

After all pipe sections are connected, the next logical step is conducting a thorough inspection for leaks. Several methods can be employed, with one of the simplest being a visual examination. Look for any signs of moisture or water dripping from connections.

Additionally, pressurizing the system temporarily can be an effective strategy. Using a pressure gauge, monitor the readings for any drops that may indicate a leak. If a leak is detected, it is crucial to address it immediately. This could involve remaking the connection or applying additional sealing material. Ensuring leak-free connections guarantees the efficiency and long-term sustainability of the solar heating system.

7. REGULAR MAINTENANCE TIPS

Routine maintenance is critical to the longevity of solar aluminum-plastic piping systems. Establish a schedule to check for signs of wear or damage, particularly at connections. Often, the joints are where issues arise due to stress or shifting in the ground.

Furthermore, consider flushing the system periodically to eliminate any sediment or buildup within the pipes. This practice helps maintain optimal flow rates and ensures that the heating system operates at peak efficiency. By taking proactive measures, one can avoid costly repairs and maximize the return on investment in solar technology.

8. ADVANTAGES OF SOLAR ALUMINUM-PLASTIC PIPING

The transition to aluminum-plastic piping for solar applications carries significant advantages. The inherent strength and lightweight characteristics of these pipes simplify handling and installation while offering considerable durability. Additionally, they resist environmental factors such as UV rays and corrosion, fostering enhanced longevity.

Energy efficiency stands out as one of the most appealing benefits. The thermal transfer properties of these pipes promote enhanced performance across various solar heating systems. This efficiency, combined with reduced maintenance needs, results in lower operational costs and greater reliability, highlighting why more homeowners and businesses are gravitating toward solar technology.

9. COMMON CHALLENGES

While the installation of these pipes is generally straightforward, several challenges may arise. Misalignment of the pipes can lead to stress at connections, increasing the risk of leaks. Attention to detail during installation mitigates many of these issues.

Additionally, fluctuating temperatures can impact the integrity of connections in the long term. Expansion and contraction of the materials may result in loosening joints; therefore, it is vital to select quality fittings designed to accommodate these shifts. Understanding these potential challenges can enhance preparation efforts and prevent future complications.

FREQUENTLY ASKED QUESTIONS

WHAT IS A FOUR-WAY PIPE CONNECTION?

A four-way pipe connection allows four pipe branches to join at a single fitting, significantly enhancing the flexibility of a piping system. In the context of solar heating applications, this fitting enables optimal routing for fluid transfer while maintaining a compact design. Properly implementing this connection provides numerous advantages, such as improving heat distribution efficiency and allowing easy access for maintenance or modifications. Each inlet facilitates the connection of pipes coming from different angles, ensuring that the system can effectively manage fluid flow and temperature transfers between various solar components.

HOW DO I DETECT LEAKS IN MY SOLAR PIPE SYSTEM?

Identifying leaks in a solar pipe system is crucial for ensuring optimal performance. Initial visual inspections at the joints and fittings can reveal telltale signs of moisture. Beyond this, pressurizing the system and observing any significant drops in pressure showcases whether leaks are present. Other methods include using soap solutions to create bubbles, indicating escaping air or water, while more technical solutions involve specific leak detection devices. Prompt detection and remediation of leaks are essential, as undetected issues can lead to system inefficiencies or potentially severe damages over time.

CAN I USE REGULAR PVC PIPE FOR SOLAR APPLICATIONS?

Using regular PVC pipes for solar applications is typically not advisable due to their inherent material limitations. Although PVC pipes are suitable for standard plumbing, they lack the thermal conductivity and durability required for solar heating systems. Solar aluminum-plastic pipes provide better resistance to temperature fluctuations and possess properties that enhance efficiency. Furthermore, regular PVC may degrade when subjected to prolonged exposure to UV radiation, ultimately compromising the entire system. Therefore, using specific materials designed to withstand the demands of solar installations ensures the longevity and reliability of the system.

Utilizing solar aluminum-plastic pipes enhances the overall efficacy and efficiency of solar heating systems. The installation process requires meticulous attention to ensure proper connections and to mitigate issues such as leaks. By adhering to best practices related to preparation, assembly, and maintenance, installers can assure that their solar piping systems endure the elements while delivering reliable performance. Ongoing vigilance through regular inspections and maintenance fortifies the system by ensuring all components remain in optimal condition.

Moreover, understanding both the benefits and challenges associated with these installations empowers users to make informed decisions in managing their solar systems. As interest in renewable energy sources continues to grow, honing skills in effectively connecting and maintaining solar aluminum-plastic piping will remain invaluable, contributing to more sustainable living practices. The journey toward harnessing solar energy is undoubtedly rewarding, as it not only supports personal energy independence but also aids in broader environmental conservation efforts.

By mastering the connection methods, attending to maintenance, and staying informed about advancements in technology and practices, individuals can navigate the complexities of their solar heating systems with confidence and assurance in the results. This pragmatic approach advocates for a sustainable future while ensuring users realize the full potential of their solar investments.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-aluminum-plastic-pipe-four-way/