The process of connecting the pipes of a solar radiator is essential for an efficient solar heating system. 1. Understand the layout and type of solar radiator being used, as this determines the lengths and types of pipes required. 2. Ensure all components are compatible and properly sized for optimal performance. 3. Follow manufacturer instructions closely to avoid potential issues during installation. 4. Use appropriate materials and fittings to ensure durability and watertight seals. Proper installation will result in better heat transfer and energy savings, benefiting the overall system.

1. DESIGN AND LAYOUT INTEGRATION

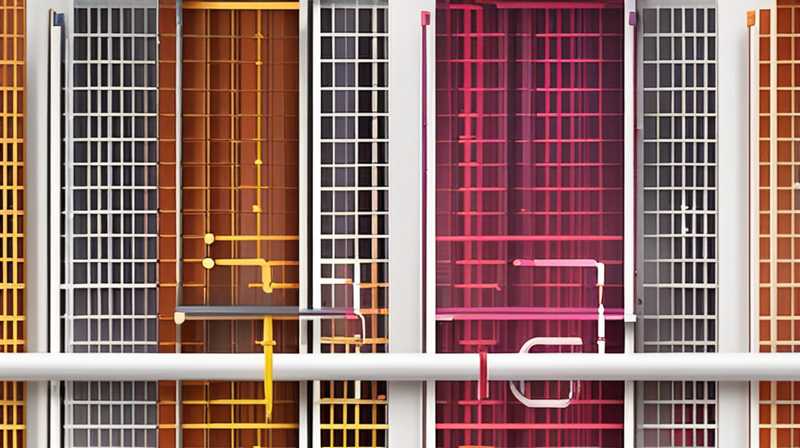

Incorporating solar radiator systems requires a meticulous approach to design and layout. Choosing the right location is paramount, as the positioning of the solar collectors significantly impacts their efficiency. Optimal locations typically receive maximum sunlight exposure throughout the day. Understanding the local climate, seasonal variations, and potential shading from nearby structures is essential to maximizing solar energy harnessing. When laying out a solar radiator system, taking into account the angle of installation for solar panels to capture the sun’s rays effectively can lead to increased heat absorption and system performance.

Furthermore, the overall layout of connecting pipes involves strategic planning. Consideration should be given to distances between components, as excessive lengths can introduce inefficiencies through energy loss and increased heat dissipation. Utilizing a blueprint or schematic diagram to visualize pipe routing facilitates smoother installation. Proper pipe insulation plays a crucial role in minimizing heat loss, ensuring that the energy collected by the solar panels effectively transfers to the heating system. Therefore, careful evaluation of layout and design is essential at this stage.

2. COMPONENTS AND MATERIALS

To successfully connect the pipes of a solar radiator, utilizing appropriate components and materials is crucial. Selecting high-quality pipes that are resistant to corrosion and temperature fluctuations will enhance the longevity and reliability of the system. Materials commonly used include copper, PEX, and PVC, each with its advantages and disadvantages. Copper, known for its excellent thermal conductivity, is a preferred choice for high-performance systems, although it can be more costly and challenging to install. On the other hand, PEX is flexible, allowing for easier maneuverability during installation; however, it may not withstand high temperatures as effectively as copper.

Alongside the piping material, fittings and connectors are integral components in the installation process. Fittings must match the designated pipe size and type to ensure a secure and leak-free connection. Various types of fittings are available, such as elbows, tees, and unions, allowing for flexible configurations in layout. Beyond just the fittings, appropriate sealing mechanisms should be employed, like thread sealants or Teflon tape, to prevent leaks. Proper selection and installation of components are imperative to achieving an effective heating solution.

3. INSTALLATION TECHNIQUES

Executing the installation of solar radiator pipes involves several key techniques to ensure a successful outcome. First, accurately measuring and cutting the pipes to the correct lengths is essential, as precision impacts the overall system efficiency. When cutting pipes, utilizing specialized tools, such as pipe cutters or saws, can provide smooth edges to prevent disruptions in flow. Ensuring that all cuts are clean reduces the risk of leaks and potential future issues.

Once cuts are made, joining the pipes with proper techniques is necessary. Methods of joining pipes like soldering for copper or crimping for PEX must be performed skillfully to create durable connections. During soldering, it’s important to apply heat uniformly to prevent joint failures. With PEX, using a crimping tool to secure connectors ensures a tight fit and helps maintain the integrity of the flow. Important to this installation process is testing each joint for leaks after the entire system is connected, utilizing pressure tests to verify the robustness of the connections.

4. GROUNDING AND CIRCULATION SYSTEM

Establishing a reliable circulation system is critical for the efficient operation of solar radiators. Incorporating a pump into the system facilitates the flow of liquid between the solar collector and the storage tank, enabling effective heat transfer. When selecting a pump, factors like flow rate and head pressure must match the requirements of the solar radiator system. Ensuring the proper capacity will prevent strain on the system and safeguard against operational disruptions.

In addition to the pump, implementing a grounding system is vital for safety. This involves establishing a grounding wire that connects the system to a ground rod, providing a pathway for electrical surges or faults to dissipate safely into the earth. Grounding long-term reliability and safety within the solar heater installation process is essential. Thus, addressing circulation and grounding aspects provides a comprehensive solution in ensuring the longevity and efficacy of the complete solar heating system.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON MATERIALS USED FOR SOLAR RADIATOR PIPES?

In the realm of solar heating systems, several materials are preferred for constructing pipes. Copper is often lauded for its superior thermal conductivity, contributing to more efficient heat transfer. It withstands high temperatures and is relatively durable against typical weather conditions, making it a prime choice for many solar installations. However, its higher cost and installation complexity can be drawbacks for some users.

On the other hand, PEX (cross-linked polyethylene) presents significant advantages due to its flexibility, ease of installation, and resistance to corrosion. It can easily bend around obstacles, which can reduce the need for excessive fittings. Although it may not endure very high temperatures as well as copper, advancements in PEX technology have enhanced its performance in solar applications. Lastly, PVC is also utilized in some applications, primarily for its affordability, but it may not offer the same level of efficiency as copper or PEX. Each material has its benefits and limitations, which should be evaluated concerning the specific installation requirements and conditions.

HOW DO I MAINTAIN MY SOLAR RADIATOR PIPES?

Maintaining solar radiator pipes is crucial for ensuring their longevity and optimal performance. Regular inspections should be conducted to identify signs of wear, corrosion, or leaks. During these inspections, visual checks can reveal areas where insulation may be failing or where moisture has accumulated, which could indicate a potential leak. If insulation appears damaged, replacement is advisable to prevent heat loss and inefficiencies.

Additionally, flushing the system periodically is recommended to remove any debris or sediment that may have built up over time. This can help maintain clean pipes and ensure optimal fluid flow within the system. Proper pressure testing of the pipes will highlight any weak points or potential leaks that might compromise overall system efficiency. Lastly, keeping connections tight and secured minimizes the risk of disturbance from external factors such as vibrations or temperature fluctuations.

WHAT TO DO IF MY SOLAR RADIATOR PIPES LEAK?

When encountering leakage in solar radiator pipes, prompt action is necessary to mitigate damage and restore system functionality. First, the source of the leak must be identified; carefully inspect joints, fittings, and connectors for any signs of moisture or corrosion. If the leak originates from a connection, retightening the fitting may resolve the issue. If the leak persists after retightening, disassembly of the fitting may be required to inspect the sealant or joint condition.

In the case of a pipe failure, replacement of the affected segment may be necessary. Cutting out the damaged section and replacing it with a new piece should restore function. Ensuring that all joints are properly sealed post-repair will prevent future leaks. Following the repair, it is wise to conduct a pressure test to verify the integrity of the entire system before returning to normal operation. By addressing leaks promptly and effectively, the overall health and efficiency of the solar heating system can be maintained.

Properly connecting the pipes of a solar radiator is essential for enhanced performance and longevity of solar heating systems. Through meticulous planning, appropriate selection of materials, and skilled installation techniques, one can achieve an efficient heating solution. The intricacies of installing this system—from the layout and design to circulating mechanisms and maintaining safety—require a detailed, precise approach. Each component in the assembly plays a significant role in efficient heat transfer and overall system functionality. Addressing potential issues preemptively leads to a significant reduction in maintenance costs over time, thus maximizing savings and energy efficiency in the long run. To attain the best results from a solar heating system, effective connection of the pipes must be prioritized, taking into account all factors that influence performance, safety, and durability. Investing time and resources into proper setup and maintenance will ultimately yield greater benefits and satisfaction from solar energy utilization.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-pipes-of-solar-radiator/