When connecting pipes in a solar room, it is crucial to follow a methodical approach to ensure optimal performance and prevent any potential issues. 1. Begin by selecting appropriate piping materials, 2. Ensure correct sizing and layout for the system, 3. Properly assemble connections to prevent leaks, 4. Conduct thorough testing to confirm functionality. One aspect that warrants detailed attention is the choice of piping materials. The right materials, such as copper or PVC, influence not only potential heat retention but also resistance to environmental factors, ultimately affecting the system’s longevity and efficiency.

1. UNDERSTANDING THE SOLAR SYSTEM REQUIREMENTS

Before initiating any installation work, it is essential to ascertain the specific demands of the solar heating system. A comprehensive grasp of system specifications enables one to select the most suitable materials and pipe configurations. This phase also involves evaluating the system’s layout and performance expectations to lay the groundwork for effective design.

Design specifications vary depending on whether the solar system is for domestic, commercial, or industrial applications. Each category comes with unique load capacities and pressure regulations that impact pipe choice. Moreover, understanding the geographical location influences factors such as freezing temperatures and ultraviolet (UV) exposure, necessitating robust materials and proper insulation techniques.

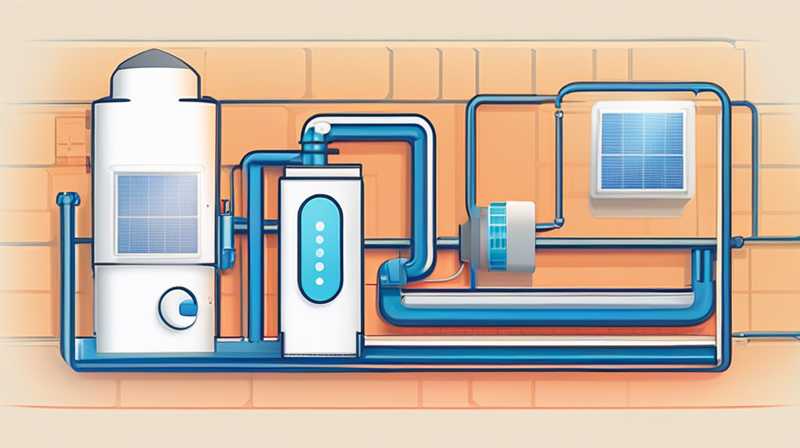

Installation layout plays a crucial role in determining how heat will be transferred within the system. Schematic representations aid in visualizing the setup, helping to minimize mistakes during assembly. Precise diagrams clarify pipe paths, showcasing where joints and bends will occur, which is vital in avoiding unwanted pressure drops and inefficiencies.

2. SELECTING PIPING MATERIALS

Choosing the right materials is fundamental to the longevity and effectiveness of the solar heating system. Common materials utilized include copper, PVC, and PEX, each possessing its own set of advantages and disadvantages that should be carefully assessed.

Copper has been a traditional choice due to its excellent thermal conductivity and durability. Although it might be more expensive than alternatives, its long lifespan compensates for the initial investment. Copper’s ability to resist corrosion makes it ideal for many scenarios, especially in regions susceptible to harsh weather or fluctuations in temperature.

PVC, on the other hand, is lightweight and cost-effective, making it a popular option for low-pressure systems. However, its heat tolerance is relatively limited, requiring careful consideration of operating temperatures. Proper insulation is essential when using PVC, as it can warp under excessive heat, potentially leading to system failure.

PEX (cross-linked polyethylene) is increasingly favored in residential installations due to its flexibility, resistance to scale build-up, and lower installation costs. However, it is crucial to note that PEX is not UV-resistant, necessitating protection from sunlight to prevent degradation over time.

3. PIPE SIZING AND LAYOUT

Effective pipe sizing is pivotal to ensure efficient fluid transfer and optimal system performance. Appropriately sized pipes minimize friction losses and pressure drops, ensuring that the solar heating system operates at its intended efficiency.

Common guidelines suggest calculating the diameter based on the expected flow rate and the specific heat transfer requirements. Oversized pipes may lead to increased costs and unnecessary material use, while undersized pipes can result in inadequate flow and subpar heat transfer.

System layout is equally critical. Proper pipe routing ensures minimal bends and turns, significantly reducing potential energy loss. For best results, aim to create a design that allows for the most direct flow path, limiting the need for additional fittings that might introduce pressure drops.

4. ASSEMBLY AND CONNECTIONS

Connecting pipes correctly is one of the most crucial aspects of the entire project. A poor connection can lead to water leakage, reduced efficiency, and potentially costly repairs down the line.

Employing suitable joining techniques is essential; choices range from soldering and solvent welding to the use of mechanical fittings. Each method has its specific applications and merits depending on the pipe material and system pressure.

Additionally, the application of Teflon tape or pipe sealants can further enhance the integrity of connections. These materials are particularly useful in ensuring leak-proof joints, thereby solidifying the entire network of pipes.

5. TESTING AND COMMISSIONING

Conducting thorough testing before placing the system into operation is non-negotiable. This stage verifies that all connections are intact and the system performs as intended under expected operating conditions.

Common tests include pressure testing to ensure that no leaks are present. This involves filling the system with water and applying pressure above the operating level for a specified period. Any drop in pressure signals a potential leak requiring immediate attention.

Temperature testing is also crucial, especially when evaluating a solar heating system’s efficiency. Monitoring the system’s output can reveal how well it captures and retains heat, facilitating adjustments and ensuring peak performance.

6. MAINTENANCE AND INSPECTIONS

Continuously monitoring the solar system is vital for sustained performance. Regular check-ups help identify potential issues before they escalate into significant problems.

During maintenance, ensure that all connections remain tight and free from corrosion. If using materials such as copper, be conscious of any signs of discoloration, indicating potential corrosion or material degradation.

Inspections should also include a review of insulation, ensuring it remains intact to prevent heat loss. Regular attention to these facets helps sustain efficiency and prolong the lifespan of the system, resulting in cost savings over time.

FAQS

WHAT TYPE OF PIPING IS BEST FOR SOLAR INSTALLATIONS?

Determining the best piping material for solar installations involves assessing environmental factors, system type, and budget constraints. Copper is widely recognized for its superior thermal conductivity and longevity, making it an excellent choice for many applications. Yet, its higher cost may deter some users. Conversely, PVC provides an affordable alternative, particularly in low-pressure systems, but its limitations in heat resistance may necessitate careful usage. Finally, PEX combines flexibility and cost-effectiveness, suitable for residential systems, albeit it lacking UV resistance. Selecting the optimal material should be a well-informed process, carefully considering both initial expenses and long-term performance.

HOW DO YOU ENSURE THERE ARE NO LEAKS IN THE SYSTEM?

To guarantee leak-free connections in a solar heating system, several practices should be adhered to. First, proper assembly techniques are crucial; whether soldering copper, using solvent-weld methods for PVC, or employing mechanical fittings for PEX, following manufacturer’s instructions will help mitigate risks. Applying Teflon tape or sealant at joints enhances joint integrity significantly. Conducting rigorous pressure tests during the commissioning phase is another integral step, revealing potential leaks by monitoring pressure fluctuations over time. Regular inspections further reinforce leak prevention by allowing users to spot wear and potential failure points early, ensuring long-term system reliability.

WHAT MAINTENANCE IS REQUIRED FOR SOLAR HEATING SYSTEMS?

Maintaining solar heating systems encompasses several vital tasks that can enhance their functionality and longevity. Regularly inspecting connections is imperative to identify any signs of leaks, rust, or deterioration. Users should also check the insulation for damage, ensuring it remains effective in heat retention. Periodic cleaning of solar collectors prevents dust accumulation, optimizing sunlight absorption and efficiency. Additionally, evaluating the fluid levels and ensuring proper circulation within the system is essential for maintaining hydraulic balance. Engaging a professional for an annual comprehensive inspection is recommended, as they can provide insights and specialized care tailored to the system’s unique needs.

The process of connecting pipes in a solar room necessitates a thorough, strategic approach to ensure a reliable and efficient operation. Every component, from material choice to system layout, plays a significant role in achieving optimal functionality. Prioritize the selection of top-quality materials that align with the specific requirements of your system. Pay close attention to sizing, as oversized or undersized pipes can lead to inefficiencies that could potentially undermine the entire setup. Ensure connections are secure and leak-proof, as any compromise can lead to costly repairs or downtime. Implement a robust testing protocol before commissioning while also conducting regular maintenance thereafter. Adhering to these guidelines not only assures a functional setup but also enhances the longevity and performance of the solar heating system, resulting in substantial energy savings and satisfaction in the long run.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-pipes-in-the-solar-room/