1. This process involves several key steps: Selecting the appropriate fittings, ensuring a secure seal, and verifying the alignment of the valve with the piping system. 2. Proper installation enhances system efficiency and longevity. 3. Regular maintenance helps prevent leaks and ensures optimal performance. 4. A thorough understanding of the components involved is crucial for successful installation.

INSTALLING A PIPE TO A SOLAR AIR RELEASE VALVE

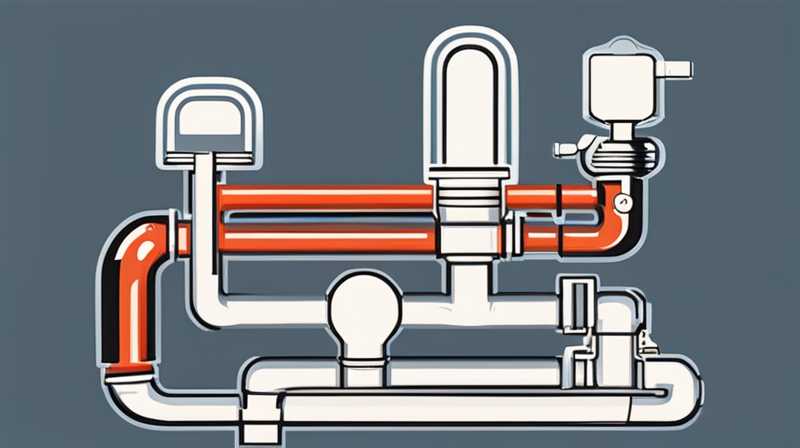

Connecting a pipe to a solar air release valve is a critical task that ensures the efficiency and effectiveness of a solar heating system. Like any plumbing task, it requires precision and knowledge of the system components to avoid inefficiencies or damages. This valve plays a vital role in eliminating air trapped within the system, which can otherwise impede circulation and decrease the system’s overall performance.

IMPORTANCE OF A SOLAR AIR RELEASE VALVE

The solar air release valve serves a paramount function in various solar heating systems. Its main purpose is to expel trapped air that can accumulate within the system, preventing optimal fluid flow. When air is trapped, the heat transfer efficiency drops significantly, reducing the effective heating of water or fluid traveling through the solar collectors. This inefficiency is not just a minor inconvenience; it can lead to major performance issues, increased energy costs, and potential system failures.

For systems relying on circulation pumps, air can disrupt the pump operation, leading to cavitation. This phenomenon can cause significant damage over time, ultimately resulting in expensive repairs or even complete system replacement. Therefore, the installation of a solar air release valve must be approached with nothing less than professionalism and attention to detail.

REQUIRED TOOLS AND MATERIALS

To successfully connect the pipe to the solar air release valve, a few specific tools and materials are necessary. The fundamental tools include a pipe cutter, a wrench, Teflon tape, and possibly a soldering iron, depending on the type of piping material used. Each tool serves a unique function; while the pipe cutter ensures a clean cut on the piping, the wrench is indispensable for securing fittings tightly.

In terms of materials, it is important to select the right fittings that are compatible with both the pipe and the valve. Common materials for solar applications include PVC, copper, and PEX. Using the appropriate fittings and pipes ensures durability and prevents leaks in the long run. Furthermore, it’s prudent to have additional seals, brackets, and screws on hand, as they may be needed for a secure installation.

SELECTING THE PROPER FITTING

Understanding Fitting Types

Choosing the correct fittings for connecting the pipe to the solar air release valve is crucial. Specific fittings such as elbows, tees, or couplings can affect how seamlessly the installation proceeds. When selecting fittings, consider the specific requirements of the system and the valve, including compatibility with the pipe material.

For instance, if you’re working with PVC piping, you will require PVC-specific fittings to ensure a leak-proof joint. Similarly, metal pipes may necessitate threaded or compression fittings, depending on the installation method. Understanding the compatibility of materials and fittings’ structure will prevent potential installation issues.

Factors to Consider in Fitting Selection

Several considerations should factor into your selection of fittings. First, assess the operating pressure and temperature of your solar heating system. Higher pressures will require fittings rated for those specifications.

Additionally, environmental conditions should also be evaluated. If the system is installed outdoors, UV-resistant materials may be necessary to prevent degradation. By taking these factors into account, one can make informed decisions that foster a successful installation process.

INSTALLATION PROCEDURE

Preparing the Workspace

Before initiating the installation, it’s vital to prepare the workspace accordingly. Ensure that all tools and materials are at hand and that the area is clear of any obstructions. Having a well-organized environment facilitates a smoother workflow.

Next, verify the existing piping layout to understand where the air release valve will be positioned. Proper positioning helps in maintaining high efficiency and also makes future maintenance easier. Mark the point on the pipe where you need to make a cut for fitting the valve.

Cutting the Pipe

Using a pipe cutter, make a clean and straight cut at the marked point on the pipe. Avoid using hacksaws or abrasive cutting tools, as they can leave jagged edges that lead to leaks.

Once the pipe is cut, it’s essential to deburr the edges; this precaution prevents any potential obstruction and ensures a perfect fit when connecting to the valve. Deburring can be performed with a deburring tool or even a piece of sandpaper, smoothing out any rough edges.

ATTACHING THE VALVE

Sealing the Connection

After the pipe has been cut and prepared, the next step is attaching the valve. Apply Teflon tape around the threads of the pipe fitting for a watertight seal. This step is especially critical in avoiding leaks, which are common in connections.

Carefully screw the valve onto the fitting, ensuring it is aligned properly. An important point to remember is to avoid overtightening, as this can potentially damage the valve threads. A secure, snug fit should be achieved without excessive force.

Final Checks Before Completion

Once the valve is fitted, it is prudent to double-check all connections before moving on to the next step. Inspect for any potential leaks and ensure that the air release valve is in the correct orientation. The valve should open toward the sky to effectively expel trapped air.

Additionally, examine the entire piping system to ensure that everything is securely fitted and there are no loose parts. A thorough check can mitigate future complications and ensure that the system will function optimally.

VERIFYING ALIGNMENT AND FUNCTIONALITY

Ensuring Proper Alignment

After installation, confirming the alignment of the piping system is essential. Misalignment can lead to stress on the joints, causing leaks or even complete failure. Carefully inspect the entire layout to make sure it conforms to the original design plan.

Using a level tool may be beneficial in assessing the alignment, particularly in complex systems. Proper alignment allows for smooth fluid flow, maintaining efficiency and prolonging the life of your solar heating system.

Testing for Functionality

The final step in connecting the pipe to the solar air release valve is testing the entire system. Fill the system with fluid and observe the functionality of the valve. Ensure that it operates as intended, effectively releasing trapped air without any leaks.

In addition, monitor the fluid circulation to ensure that the system performs as desired. A successful installation should result in a well-functioning solar heating system that operates at optimal efficiency.

MAINTENANCE TIPS

Regular Inspections

Maintaining the functionality of the solar air release valve and connected piping is essential for long-term efficiency. Regular inspections should be conducted to check for any signs of wear and tear, leaks, or other issues that could impair system performance.

During these inspections, ensure that the valve is functioning correctly and that it opens without obstruction. The valve should be cleaned periodically to remove any debris or mineral deposits that may restrict its performance. A clean and well-maintained valve can significantly extend the lifespan of the entire system.

Routine Testing

Performing routine tests on the system will help identify issues before they escalate into costly repairs. Monitor the inlet and outlet temperatures to assess the system’s efficiency. If discrepancies occur, they may indicate trapped air or malfunctioning components.

Taking the time to regularly analyze the performance of the solar heating system will prevent costly repairs down the line and ensure that the system operates at its best.

COMMONLY ASKED QUESTIONS

WHAT IS THE DIFFERENCE BETWEEN A SOLAR AIR RELEASE VALVE AND A TRADITIONAL AIR VENT?

A solar air release valve is specifically designed for solar thermal systems, targeting the unique challenges these systems face regarding trapped air. Traditional air vents, while effective in conventional plumbing systems, may not be ideal for solar applications. Solar air release valves are engineered to handle higher temperatures and pressures typical in solar heating systems.

Furthermore, these valves provide better adaptability and response to air locking situations in solar systems by releasing air quickly and efficiently. Traditional air vents may not provide the same level of efficiency, ultimately impacting the heating performance. For effective results, it’s recommended to use a valve tailored to solar applications in any solar thermal system.

HOW OFTEN SHOULD THE AIR RELEASE VALVE BE CHECKED?

It’s advisable to inspect the air release valve at least bi-annually as part of routine maintenance. Regular checks help identify any potential problems early on, preventing complications in the solar heating system.

During these checks, ensure that the valve opens and closes properly, and look for signs of wear, which might affect its performance. If the system experiences significant changes in efficiency, more frequent inspections may be warranted. Regular maintenance not only enhances performance but also prolongs the life of the system.

CAN I INSTALL A SOLAR AIR RELEASE VALVE MYSELF?

While it is possible to install a solar air release valve independently, several technical skills and tools are necessary to ensure a proper installation. If you are experienced with plumbing and feel confident in your abilities, you can certainly proceed with the installation. However, it’s vital to understand the specific requirements and steps outlined for successful installation.

If you lack experience or feel uncertain, it may be wise to consult a professional plumber or technician. Professional installation can help prevent common mistakes and ensure that the valve functions optimally within your solar heating system. When in doubt, seeking professional assistance is a wise choice.

INSTALLATION OF A PIPE TO A SOLAR AIR RELEASE VALVE IS A PROCEDURE THAT DEMANDS ATTENTION TO DETAIL AND ACCURATE TECHNIQUES. THIS PROGRAM ENTAILS A COMPLETE UNDERSTANDING OF COMPONENTS AND THEIR INTERACTION. THE SIGNIFICANCE OF A WELL-OPERATING VALVE CAN NOT BE DISREGARDED, AS IT DIRECTLY AFFECTS THE EFFICIENCY OF YOUR SOLAR HEATING SYSTEM. CONSISTENT MAINTENANCE PRACTICES AND PERIODIC CHECKS WILL INCREASE SYSTEM LONGEVITY AND PERFORMANCE. FOCUSING ON PROPER INSTALLATION WILL SET A SOLID FOUNDATION FOR A HIGHLY EFFICIENT SOLAR SYSTEM. EXPERIENCING SUCCESS IN THIS INSTALLATION IS NOT ONLY SATISFYING BUT ALSO CONTRIBUTES POSITIVELY TO ENVIRONMENTAL SUSTAINABILITY. ADMINISTERING THESE PROCEDURES WILL TRANSLATE TO AN IMPROVED FUNCTIONALITY CONVERTING TO SIGNIFICANT ENERGY SAVINGS AND A MINIMIZED CARBON FOOTPRINT IN THE LONG RUN. ABSOLUTELY, THE PATIENCE SPENT IN INITIATING THESE STEPS CAN LEAD TO A SIGNIFICANT IMPACT ON YOUR SOLAR HEATING EXPERIENCE AND A MORE SUSTAINABLE LIFESTYLE.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-pipe-to-the-solar-air-release-valve/