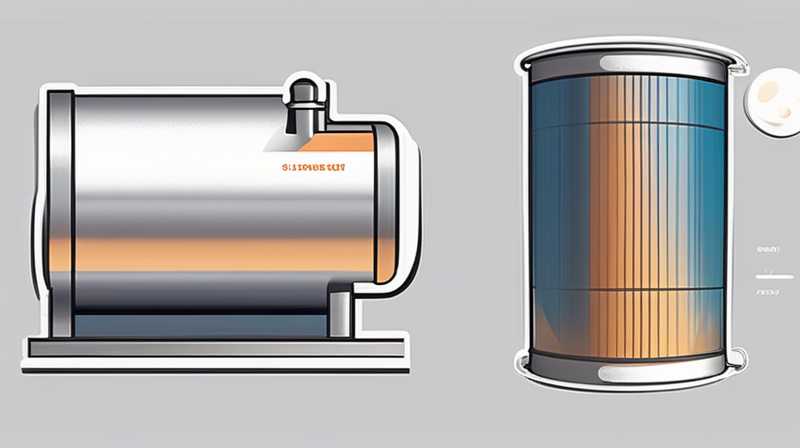

In order to achieve an effective connection of the pipe for a solar thermal insulation barrel, several key steps should be undertaken. 1. Evaluate the components for compatibility, 2. Prepare the pipes and fittings meticulously, 3. Employ reliable joining techniques tailored to the selected materials, 4. Test the system for leaks and ensure proper insulation. To prepare the pipes and fittings meticulously is essential as it involves cleaning and deburring the edges to promote a tight and long-lasting seal. This foundational work is critical in preventing inefficiencies in the solar thermal system and ultimately supports optimal energy capture and transfer functionality.

1. COMPONENT COMPATIBILITY

Understanding the compatibility of various components is the bedrock of connecting piping in solar thermal systems. This involves assessing the materials used in the pipes and fittings, as mismatched materials can lead to various issues, including corrosion, leaks, or weakening of connection points. It is common to find pipes made from materials such as copper, PEX, or PVC. Each of these comes with its own set of characteristics that impact performance, lifespan, and installation techniques.

When selecting materials, one should consider the thermal expansion properties, durability against environmental factors, and resistance to pressure changes. Copper pipes offer exceptional thermal conductivity and longevity but may require more effort during installation due to their rigid nature and welding requirements. Conversely, PEX provides flexibility and ease of installation, making it favorable for many residential installations; however, when exposed to direct sunlight over prolonged periods, its integrity may diminish. Therefore, assessing the environment and installation context is imperative in the decision-making process.

2. PREPARATION OF PIPES AND FITTINGS

Once materials are chosen, meticulous preparation is vital for achieving effective connections. Proper cleaning and deburring of the pipe edges ensure a smooth, even surface that allows for a secure joint. Any contaminants such as dust, dirt, or grease should be removed thoroughly. For metal pipes, a file can be employed to smooth out rough edges, while for plastic pipes, a deburring tool can help.

This preparatory step minimizes the risk of leaks and strengthens joint durability. Additionally, when working with fittings, one must ensure that their inside and outside diameters correspond perfectly to avoid gaps. It’s also advantageous to dry-fit the entire assembly before permanent joining to verify that all components align correctly and function as anticipated.

3. JOINING TECHNIQUES

Various joining methods are available to connect pipes in a solar thermal insulation barrel, each having specific advantages based on the materials used. Soldering and brazing are popular techniques for copper pipes, while compression fittings are commonly employed for PEX. For thermoplastic pipes, solvent welding presents a reliable solution.

When soldering, the area must first be cleaned and fluxed to create a robust bond when heated. Attention to detail during this process is non-negotiable since overheating can result in oxidization or weakening of the bond. Moreover, using the right solder material (lead-free is recommended for potable water systems) is crucial. In contrast, compressing fittings, while simpler, may require careful installation to ensure a proper seal, necessitating appropriate tools to maintain the required pressure.

4. TESTING THE SYSTEM

After making the connections, it becomes paramount to test the integrity of the entire system to prevent unforeseen leaks from causing damage. A leak test involves pressurizing the system with water or air and monitoring for any drops in pressure over a specified period. If a pressure drop occurs, it is indicative of a leak, necessitating further examination of all connection points.

Moreover, visual inspections should be routinely conducted to detect any signs of wear or impending failure. A consistent evaluation cycle—particularly after seasonal changes or significant weather events—will support the longevity and reliability of the solar thermal system.

5. INSULATION OF PIPES

Insulating the pipes connected to the solar thermal barrel is essential for enhancing energy efficiency. Proper insulation prevents heat loss, preserving the energy captured during solar heating. Insulating materials, such as fiberglass or foam sleeves, can be used to cover exposed pipes.

This not only promotes efficiency but also safeguards the pipes against potential freezing in colder climates. When installing insulation, care must be taken not to crush or damage it during application, as this would diminish its insulating properties. Furthermore, any seams in the insulation should be taped securely to prevent cold air infiltration.

FREQUENTLY ASKED QUESTIONS

WHAT MATERIALS ARE BEST FOR SOLAR THERMAL PIPE CONNECTIONS?

The choice of materials for solar thermal pipe connections largely hinges on the specific requirements of the installation. Copper is highly regarded for its excellent thermal conductivity and enduring quality, although it tends to be more expensive and requires careful soldering. PEX, on the other hand, is flexible and easier to install, making it ideal for residential systems. This comes with a caveat, as extended exposure to UV light can diminish its strength. Polyvinyl chloride (PVC) pipes are similarly popular for their low cost, although they may not endure high-temperature data as well as metal counterparts. Ultimately, the decision should consider thermal expansion properties, installation environment, and potential for corrosion, collectively determining which material aligns best with project goals.

HOW DO I IDENTIFY LEAKS IN A SOLAR THERMAL SYSTEM?

Identifying leaks in a solar thermal system involves employing several techniques. Regular visual inspections are crucial as they can unveil obvious signs of leakage, such as water stains or corrosion around joints. Pressure testing is a more rigorous method where air or water is introduced into the system, followed by observation for any drops in pressure during a specified period. A drop indicates a leak that requires further investigation. Specialized detection techniques, including infrared thermography, can also identify heat losses, signaling potential leaks within insulated sections. Maintaining vigilance through routine examinations will provide peace of mind that the system is functioning correctly and efficiently, ultimately supporting energy savings and system durability.

WHAT IS THE ROLE OF INSULATION IN SOLAR THERMAL PIPE INSTALLATION?

Insulation plays a pivotal role in optimizing the performance of a solar thermal system. By serving as a barrier to heat transfer, insulation reduces thermal loss associated with heated water traveling through pipes. This is particularly critical for systems operating in colder climates where heat loss can significantly impair efficiency. Proper insulation methods, such as foam or fiberglass, also protect pipes from environmental elements, reducing the risk of freezing in low temperatures. Furthermore, a well-insulated system requires less energy input to achieve desired temperatures, ultimately translating to lower energy costs over time. Proper installation and maintenance of insulation should not be overlooked, as damaged or improperly applied insulation can negate its intended benefits.

IS PROFESSIONAL INSTALLATION NECESSARY FOR SOLAR THERMAL SYSTEMS?

While it is possible for individuals with a background in plumbing or renewable energy systems to undertake solar thermal installations themselves, professional installation is generally recommended for several key reasons. Professionals bring technical expertise, ensuring that materials are compatible and that connections adhere to local building codes. Their experience in testing and troubleshooting can also mitigate potential issues that may not be apparent to an inexperienced installer. Additionally, professional installation typically comes with warranties and assurances that can prove invaluable should problems arise post-installation. This approach can provide homeowners with peace of mind, knowing that a qualified expert has ensured the system is set up properly to operate effectively and efficiently over the long term.

The successful connection of pipes for a solar thermal insulation barrel hinges on a multi-faceted approach involving proper material selection, thorough preparations, reliable joining techniques, and consistent testing and insulation application. Each stage of the process feeds into the overarching objective of creating an efficient, reliable solar thermal system. By understanding these components, operators can ensure their systems not only function effectively but are also long-lasting and dependable. To encapsulate this process is to recognize the significance of diligence and professionalism in every phase of the installation, thus enabling optimal performance and energy savings in solar thermal applications.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-pipe-of-solar-thermal-insulation-barrel/