1. To connect the outer pipe of a solar thermal insulation barrel, specific steps are essential. 2. Begin by preparing the components and tools for the connection. 3. Ensure that the insulation material is properly applied for increased efficiency. 4. Finally, secure all joints and check for leaks. Connecting the outer pipe of a solar thermal insulation barrel involves meticulous planning and execution to guarantee optimal performance. The outer pipe serves as a conduit for transferring heat efficiently and must be insulated correctly to maximize energy conservation. Proper methods not only enhance durability but also improve functionality and system efficiency.

1. UNDERSTANDING SOLAR THERMAL INSULATION BARRELS

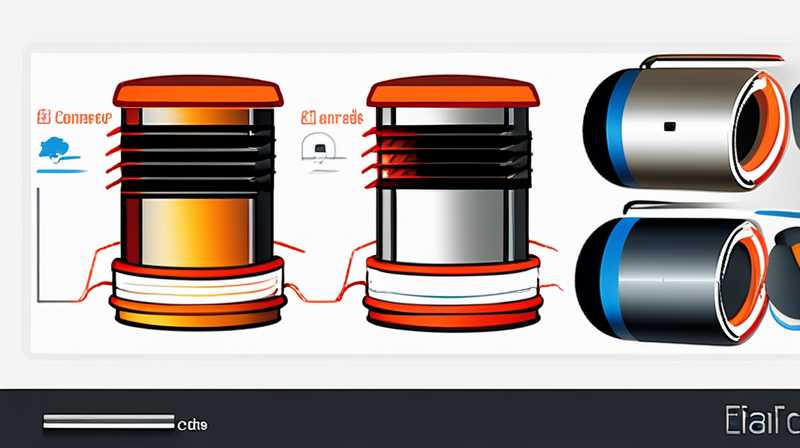

To effectively connect the outer pipe of a solar thermal insulation barrel, it is imperative to comprehend the fundamental workings of the system. Solar thermal insulation barrels are designed to harness solar energy by capturing and storing heat efficiently. This process involves the absorption of sunlight, which heats a fluid that circulates through the system. Understanding the components and their interconnections is pivotal for maximizing performance. A thorough understanding of the design and functionality streamlines the installation process, thereby preventing common pitfalls.

Several components make up the structure, including the outer pipe, insulation material, inlet and outlet fittings, and an absorber plate. Each component plays a significant role in overall efficiency. For example, the outer pipe is responsible for connecting the storage and heating elements, while quality insulation minimizes thermal losses. It is essential that individuals working with these systems possess a detailed knowledge of their interactions and the benefits of high-quality materials to enhance their longevity and functionality.

2. GATHERING NECESSARY TOOLS AND MATERIALS

Before commencing the connection process, it is crucial to assemble all necessary materials and tools to ensure efficiency and effectiveness. Adequate preparation eliminates delays and enhances the overall outcome. Common materials that will be needed include the insulated pipe, adhesive or sealant, clamps, and any necessary fittings specific to the design of the solar thermal system. A robust toolkit should comprise wrenches, screwdrivers, and potentially pipe cutters to manage the various components seamlessly.

Selecting high-quality materials is paramount to achieving a reliable connection. The type of insulation used can dramatically affect heat retention, thus impacting system efficiency. Opting for materials with high R-values minimizes conductive heat loss and maximizes thermal performance. Additionally, ensure that the fittings and connections are compatible with the specific dimensions and pressure ratings of the overall system. Comprehensive preparation allows for a streamlined installation process, ultimately leading to an efficient and effective solar thermal insulation barrel.

3. INSULATING THE OUTER PIPE

With materials in hand, the next step involves insulating the outer pipe effectively. Proper insulation minimizes energy losses and enhances the overall efficiency of the system. The insulation material should be installed around the outer pipe, ensuring that it conforms well to all surfaces. Applying insulation requires precision; gaps and uninsulated areas can lead to significant decreases in efficiency.

When choosing insulation, it is advisable to consider flexibility and thermal resistance. Specialized insulation materials suitable for solar applications help reduce heat loss. Furthermore, ensure that the insulation material is weatherproof, as outdoor installations are often subjected to extreme conditions. Once the insulation is secured in place, inspect for any potential openings or vulnerabilities. Proper adhesion and sealing are essential to maintaining an efficient thermal barrier, so taking time with this step is crucial.

4. CONNECTING THE OUTER PIPE

Now that insulation is properly applied, the focus shifts to connecting the outer pipe to the solar thermal system. A secure connection is essential for maintaining system pressure and efficiency. Begin by aligning the pipe with the corresponding fittings and connectors. Tighten all connections according to the manufacturer’s specifications to ensure a watertight seal.

Utilizing appropriate tools is vital during this phase. Over-tightening can lead to damage, while under-tightening may cause leaks. Carefully assess the entire connection, checking for any signs of wear or stress on the materials. A comprehensive check at this point can prevent future complications and enhance long-term functionality. After successfully connecting the outer pipe, it’s prudent to review the entire system’s layout, ensuring all components align properly for optimal performance.

5. TESTING FOR LEAKS AND EFFICIENCY

Following the connection of the outer pipe, a thorough leak test is necessary to guarantee operational integrity. Performing this test will identify any faults that could compromise system performance. Complex systems might require filling the circuit with water and observing for any visible leaks at connection points. Additionally, monitoring the system upon activation will assist in revealing hidden issues that may not present themselves immediately.

Subsequent to detecting leaks, evaluating the efficiency of the system is crucial. Smart monitoring devices can provide real-time data on energy output and performance. In this stage, engage in observations over a defined period, noting fluctuations in temperature and energy efficiency. If performance does not align with expectations, revisit the connections and insulation areas, ensuring that all aspects are functioning as intended. Efficient operation of a solar thermal insulation barrel hinges on each component working harmonically together, thus this testing phase cannot be overlooked.

FREQUENTLY ASKED QUESTIONS

WHAT MATERIALS ARE REQUIRED FOR CONNECTING A SOLAR THERMAL INSULATION BARREL?

Connecting a solar thermal insulation barrel involves several specialized materials and tools suited for the task. The primary materials required include an insulated pipe, high-quality sealants or adhesives, and various fittings tailored to the specific dimensions of the solar system. The insulation material, typically designed for thermal efficiency, must be weather-resistant and flexible to conform to the pipe’s surface. Additionally, accessories such as clamps can help secure the insulation properly.

In terms of tools, a standard toolkit may include wrenches, screwdrivers, and pipe cutters. The precise tools necessary will vary based on the complexity of the system and the fittings used. Thus, assessing the design beforehand is essential to avoid the risk of inefficiencies or damages during installation. Proper material selection plays a significant role in ensuring long-lasting functionality and performance, which in turn optimizes solar energy harnessing.

HOW CAN I ENSURE A LEAK-FREE CONNECTION IN MY SYSTEM?

Ensuring a leak-free connection in a solar thermal insulation barrel requires meticulous attention to detail during the installation process. Begin by aligning all components carefully and securing fittings according to the manufacturer’s guidelines. Regularly use appropriate tools to tighten connections but be cautious of over-tightening, which can cause materials to crack and ultimately lead to leaks.

One effective method to test for leaks involves filling the circuit with water and inspecting all joints and connections. Look for visible drips or moisture during this test. In addition, consider applying pressure testing techniques to identify any hidden vulnerabilities. If leaks are detected, address them promptly by retightening connections or using additional adhesive or sealant. This preventive maintenance is critical to ensuring the longevity and efficiency of the solar thermal system.

WHAT ARE THE BENEFITS OF USING HIGH-QUALITY INSULATION MATERIALS?

Utilizing high-quality insulation materials in a solar thermal insulation barrel offers several significant advantages that enhance system performance. First and foremost, quality insulation reduces heat loss, which directly translates to improved energy efficiency. High R-value materials provide excellent resistance to conductive heat flow, making them ideal for maintaining elevated temperatures within the system.

Moreover, quality insulation can significantly extend the lifespan of the components within the solar thermal system. By minimizing temperature fluctuations and thermal stress, high-quality materials help prevent degradation and deterioration over time. This ultimately leads to reduced maintenance costs and increases the reliability of the installation. Investing in superior insulation translates into enhanced capabilities, making the solar thermal insulation barrel not only more effective but also more durable.

The process of connecting the outer pipe of a solar thermal insulation barrel involves numerous strategic steps culminating in an efficient and reliable installation. Careful consideration of each phase ensures optimal energy performance, underscores the importance of meticulous preparation and selection of proper materials, and guarantees an effective and enduring connection. Emphasizing quality in every aspect, from insulation to fittings, forms the bedrock for a successful solar thermal system. By attentively following the outlined procedures, one can achieve a sophisticated integration that boosts thermal efficiency and longevity.

Furthermore, it is beneficial to continually monitor and manage the health of the solar installation throughout its lifecycle. Regular inspections and maintenance not only sustain performance but also aid in identifying potential issues before they escalate into substantial problems. Engaging with knowledgeable professionals during installation and upkeep can greatly enhance the efficiency and effectiveness of the system, ensuring that all components function in unison to yield the maximum benefits of solar energy. Ultimately, the careful connection of the outer pipe in a solar thermal insulation barrel is pivotal to achieving the desired operational excellence and harnessing the full potential of solar energy.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-outer-pipe-of-solar-thermal-insulation-barrel/