1. CONNECTION OF MOTOR AND SOLAR PANEL REQUIRES UNDERSTANDING OF COMPONENTS, PROPER WIRING TECHNIQUES, USING A REGULATOR FOR STABILITY, AND ADEQUATE MOUNTING FOR OPTIMUM SUNLIGHT RECEPTION. Connecting a motor to a solar panel involves a series of technical steps and considerations to ensure efficiency and functionality. The ideal setup will depend on the type of motor and solar panel utilized, as well as the specific application in question. Initial preparation is key, where one must gather the required parts including the motor, solar panel, necessary wiring, and occasionally a charge controller or inverter to regulate power flow. A detailed understanding of electrical principles is advantageous, particularly regarding voltage and current specifications.

To elaborate on the first point, understanding components includes assessing the specifications of both the motor and the solar panel. Every solar panel produces a certain voltage and current depending on its size and design. The motor must tolerate this output without risk of damage. For instance, small DC motors typically need around 12 volts, whereas larger motors may have different requirements. Therefore, confirming that the solar panel’s output matches these voltage demands is essential for a successful connection.

1. UNDERSTANDING THE COMPONENTS

Before embarking on the connection project, it’s crucial to have a comprehensive overview of both the motor and solar panel. Understanding these components forms the bedrock of a successful installation.

MOTOR TYPES AND SPECIFICATIONS

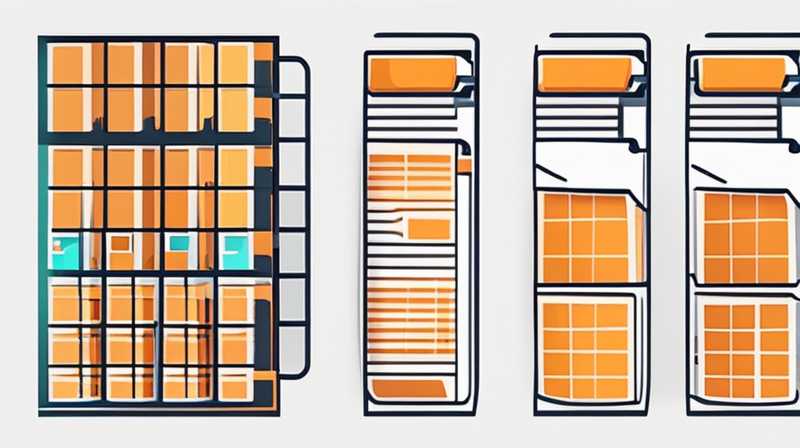

The type of motor will dictate several aspects of the connection, including voltage, current draw, and operational efficiency. DC motors are common in solar applications due to their ease of integration with solar panels. These motors operate on a direct current that can be directly supplied by solar panels, making them an excellent choice for solar energy systems. More advanced applications may employ AC motors, but these require additional equipment, such as inverters, to convert DC power from the solar panel into usable AC power for certain motor types.

SOLAR PANEL OUTPUT AND CHARGING REQUIREMENTS

When choosing a solar panel, one must pay attention to its wattage, voltage, and current output. Typically calculated in watts, the more powerful the panel, the more energy it can convert from sunlight into electrical energy. For example, a 100-watt solar panel can generate an output of roughly 18-20 volts under optimal conditions. Mismatches between the voltage of the motor and the output of the solar panel could lead to ineffective performance or even irreversible motor damage. Therefore, it is prudent to select a panel that can provide adequate power based on the specific requirements of the motor in use.

2. WIRING TECHNIQUES

Once there is a solid grasp of both components, the next step involves establishing appropriate wiring techniques that adhere to safety protocols and optimize performance.

SELECTING THE RIGHT WIRE GAUGE

Choosing the correct wire gauge is paramount for a successful connection. Thicker wires can handle higher currents and minimize voltage drop over distances, ensuring that the motor receives adequate power supply. Most professionals adhere to the American Wire Gauge (AWG) standards, which provide guidance on wire sizing based on the current requirements and the distance between the solar panel and the motor. For example, a 10 AWG wire is suitable for currents of up to 30 amps over moderate distances, making it ideal for many low-voltage motor applications.

ENSURING POLARITY AND CONNECTION SECURITY

Proper wiring also encompasses ensuring correct polarity during the connection process. The positive wire from the solar panel must connect to the positive terminal of the motor, and likewise for the negative terminals. Using connectors that provide a secure connection is vital, as loose connections can lead to arcing, overheating, and loss of efficiency. Soldering connections can create permanent links that resist disconnecting under operational stress, promoting durability and performance stability.

3. INTEGRATING A REGULATOR OR INVERTER

For many applications, especially those requiring consistent voltage, utilizing a regulator or inverter is critical.

REGULATORS FOR STABLE OUTPUT

Voltage regulators are essential devices that maintain the output voltage at a stable level, ensuring the motor operates efficiently without fluctuations that could cause malfunction or damage. These regulators will adjust the voltage automatically to ensure that the motor receives a steady current regardless of changes in sunlight intensity that may affect solar panel output. This is particularly crucial in realistic outdoor environments, where cloud cover and changing weather conditions can significantly impact solar panel efficiency.

INVERTERS FOR MOTOR TYPES

When using AC motors in solar setups, an inverter becomes indispensable. This device converts the DC output from the solar panel into AC power suitable for the motor. Inverters come in various designs, including pure sine wave and modified sine wave versions. Pure sine wave inverters produce clean power that is compatible with sensitive electronic devices and motors, thus ensuring optimal performance. Sizing an inverter correctly according to the anticipated motor load is also essential, as an undersized inverter may not handle the load effectively, leading to possible shutdowns or failures.

4. MOUNTING FOR OPTIMUM RECEIPT OF SUNLIGHT

Mounting the solar panel correctly ensures it receives maximum sunlight exposure throughout the day.

LOCATION SELECTION

Finding the optimal location for the solar panel is crucial. Ideally, it should be placed where it can receive uninterrupted sunlight for most of the day without obstructions like trees or buildings. Professionals often recommend mounting the panel at an angle that matches the latitude of the installation site, as this orientation maximizes solar absorption. The use of adjustable brackets can enhance flexibility, allowing users to tweak the angle based on seasonal changes.

SECURE INSTALLATION

Once the ideal location is established, securely mounting the panel is important. This might involve the use of brackets, bolts, and other supporting structures that resist environmental conditions such as wind and rain. Good installation practices not only provide safety and stability but also extend the lifespan of the solar panels, maintaining efficiency over time.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE DIFFERENCE BETWEEN DC AND AC MOTORS IN SOLAR APPLICATIONS?

The significant distinction between DC and AC motors lies in their power requirements and applications. DC motors operate using direct current, which means they can be easily connected to solar panels that output DC electricity. These motors are known for their simplicity, ease of control, and generally lower cost. They are commonly found in small-scale applications like pumping systems or simple robotic operations.

On the other hand, AC motors require alternating current to function. They are more efficient for larger applications and tend to offer better performance in terms of durability and power output. However, using AC motors in a solar application necessitates the use of inverters to convert the DC output from solar panels into AC power, adding complexity and additional costs to the installation. Depending on the specific project goals, one’s choice between DC and AC motors can significantly affect overall system design.

CAN I USE MULTIPLE SOLAR PANELS TO POWER A MOTOR?

Absolutely, utilizing multiple solar panels can greatly enhance the system’s overall output and enable powering more energy-intensive motors. When combining solar panels, the arrangement depends on the desired voltage and current specifications. Panels can be connected in series to increase voltage while maintaining the same current. Alternatively, they can be wired in parallel to keep the voltage constant, but increase available current.

Employing the correct combination results in a system that can effectively meet the demands of higher-powered motors. However, care must be taken to ensure that the total voltage output remains compatible with the motor specifications. Additionally, one must be vigilant about the balance in the system to prevent any damage from potential overvoltages.

HOW DO WEATHER CONDITIONS AFFECT SOLAR PANELS AND MOTOR PERFORMANCE?

Weather conditions have a profound impact on both solar panel performance and the efficiency of any connected motors. Direct sunlight is essential for optimal solar panel function. During cloudy days or prolonged periods of rain, the panels may produce significantly less energy, which can limit motor performance. Hence, in systems that require continuous operation, relying solely on solar power might necessitate the inclusion of battery storage to supply energy during inclement weather.

Moreover, high temperatures can negatively affect the efficiency of solar panels, while extreme cold may lead to reduced motor performance or even mechanical stress if not adequately designed to cope with these conditions. Understanding the local climate is important when designing a system, as it can pave the way for adapting components and achieving consistent performance throughout the year.

THE CONNECTION OF A MOTOR AND SOLAR PANEL REQUIRES A COMPREHENSIVE UNDERSTANDING OF IMPORTED COMPONENTS, EFFECTIVE WIRING TECHNIQUES, AND A FOCUS ON STABILITY THROUGH REGULATORS OR INVERTERS. PROPER MOUNTING ENSURES THAT SOLAR PANELS OPTIMALLY HARVEST ENERGY. ENJOYING THE COMMITMENT TO ADDRESSING EACH ELEMENT WILL RESULT IN A FUNCTIONAL AND EFFICIENT SYSTEM. WITH CLEAR KNOWLEDGE OF THE COMPONENTS INVOLVED AND THEIR FUNCTIONALITY, ENTHUSIASTS CAN EMBARK ON PROJECTS DESIGNED TO HARNESS SOLAR ENERGY WITH MAXIMUM EFFICIENCY. PRIOR TO STARTING ANY INSTALLATION, IT IS ADVISED TO TAKE INTO ACCOUNT LOCAL REGULATIONS AND SAFETY MEASURES, AS REGULATORY COMPLIANCE ENSURES A LONG-LASTING, SAFE, AND EFFECTIVE SYSTEM. ENCOURAGINGLY, AS TECHNOLOGIES EVOLVE, THE OPPORTUNITIES FOR RENEWABLE ENERGY SYSTEMS CONTINUE TO GROW, PROMOTING SUSTAINABILITY AND ENVIRONMENTAL RESPONSIBILITY IN THE PROCESS.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-motor-and-solar-panel/