How to Connect the Lower Port of Flat Panel Solar Panel

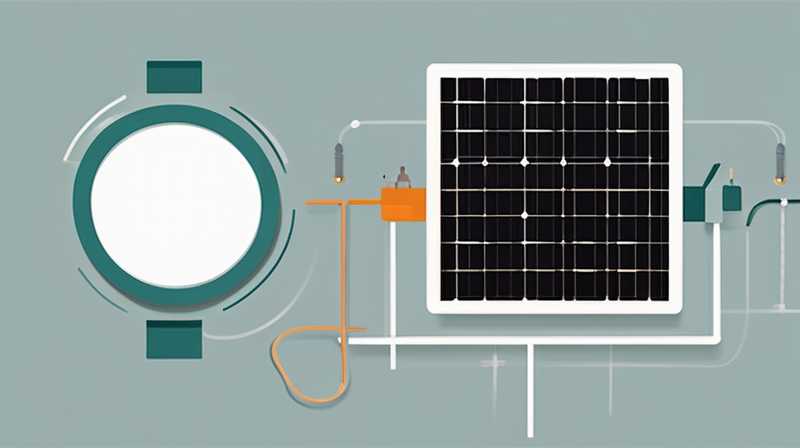

In order to effectively connect the lower port of a flat panel solar panel, 1. identify the specific port, 2. select appropriate connectors, 3. ensure correct wiring, and 4. secure connections properly. The process involves detailed steps that include assessing compatibility with the solar system and safety precautions. For further elaboration, recognizing the significance of correct installation is essential, as improper connections can lead to decreased efficiency or potential damage to the solar panel system.

1. UNDERSTANDING FLAT PANEL SOLAR PANELS

The design of flat panel solar panels is both functional and intricate. These devices capture sunlight and convert it into electricity through photovoltaic cells embedded within the panels. Among various components of these systems, the lower port serves a pivotal role when it comes to the power output and connection to the rest of the solar setup.

Understanding the operational aspects of solar panels requires an examination of their components and how they interrelate. The lower port typically features connectors that allow for cable routing to the inverter or battery storage system. It is essential to recognize the types of ports commonly present in flat panel systems, as various manufacturers may use different standards and configurations for their devices.

The design of the lower port also contributes to the overall performance of the solar panel. Each connection point is engineered to optimize electrical flow and minimize resistance, ensuring maximum efficiency. Therefore, comprehending the mechanics behind the lower port is vital for anyone involved in installing or maintaining solar energy systems.

2. GATHERING NECESSARY TOOLS AND MATERIALS

When embarking on the task of connecting the lower port of a flat panel solar panel, having the appropriate tools and materials is crucial. Essential tools typically include wire strippers, screwdrivers, and multimeters for testing current flow. Additionally, specific components such as connectors suited for solar applications, along with electrical tape and zip ties for organizing cables, will be necessary.

The importance of selecting high-quality materials cannot be overstated. Subpar connectors may lead to increased resistance and potential power losses while degrading performance over time. Therefore, it is prudent to invest in certified equipment to ensure long-lasting and efficient connections. Always refer to the solar panel’s manufacturer guidelines to identify which materials are required for the particular model being installed.

In preparation for the installation, it is advisable to assess the environment where the panels will be positioned. Factors such as the climate, orientation, and potential shading are critical in determining where connections might be made. These considerations aid in ensuring that solar panels function at optimum capacity.

3. CONNECTING TO THE LOWER PORT

To initiate the connection process, the first step involves locating the lower port on the flat panel. The panel’s design will often indicate the port position, typically at the bottom or rear side. Once identified, the next step involves cleaning the connection points. Dust and grime can obstruct connections, so using a clean cloth to wipe any debris is recommended.

After the port is sufficiently prepared, individuals must then select the correct gauge of wire compatible with the solar panel’s specifications. Connecting the wires involves stripping the insulation and properly twisting or crimping the ends to form a secure connection. It is vital to ensure that polarity is maintained, meaning positive and negative terminals must align correctly to prevent malfunction.

Once the wires are affixed, it is essential to test the connections using a multimeter to verify functionality. This step ensures that energy transfer is flowing as intended. If the reading is not within expected ranges, re-examine connections and troubleshoot any discrepancies.

4. SECURING AND PROTECTING CONNECTIONS

With the connections complete, the focus shifts to securing and protecting them. Utilizing electrical tape can help insulate the wiring and prevent moisture ingress, which can lead to corrosion and electrical shorts. Employing zip ties is also beneficial in organizing the cable layout, minimizing the risk of tangled wires which could lead to damage over time.

Furthermore, it is crucial to ensure that the entire setup adheres to local electrical codes and safety regulations. Compliance with these standards is essential not only for personal safety but also for meeting requirements for warranties and insurance claims that may arise.

Regular inspection of connections should form part of ongoing maintenance. This practice will help detect wear and tear or issues stemming from environmental factors such as severe weather conditions. Implementing preventative measures can prolong the lifespan of the system and ensure optimal energy production throughout its operation.

5. MONITORING PERFORMANCE AND TROUBLESHOOTING ISSUES

As the solar panel system begins operation, ongoing monitoring will be necessary to assess performance. Utilizing monitoring tools connected to the inverter can provide insights into energy production and any irregularities that may arise. Regularly checking the output compared to expected performance metrics can shed light on potential issues that require attention.

Common issues might include unexpected decreases in energy production or physical signs like scorching or discoloration on the panel surface. If problems are identified, it might necessitate inspecting all connections and wiring to ensure integrity throughout the system.

In cases where troubleshooting reveals serious faults, consulting a professional installer might be prudent. Their expertise ensures that any diagnosed issues are addressed correctly and safely, protecting the investment in solar technology.

Frequently Asked Questions

WHAT ARE THE COMMON TYPES OF SOLAR PANEL CONNECTIONS?

Solar panels typically utilize several connection types that play a crucial role in energy transfer. The most common forms consist of MC4 connectors, which are standardized for efficient connections, particularly for larger systems. These connectors securely clip together, providing a waterproof seal and preventing accidental disconnections. In smaller applications, alligator clips might be utilized, offering flexibility for temporary setups. Ensuring that connectors are suitable for the environment, such as being UV resistant, is crucial for longevity. Additionally, junction boxes within solar panels interface with the wiring system, managing connections safely. Understanding the various types of connections facilitates proper setup and maintenance, ensuring optimal performance of the solar energy system.

HOW CAN I DETECT ISSUES WITH MY SOLAR PANEL CONNECTIONS?

Detecting problems with solar panel connections generally start with visual inspections. Observing the panels for discoloration, cracks, or physical damage can provide initial indicators of underlying issues. Regular monitoring of energy production becomes critical; if the output falls short of expectations, it may signify connectivity problems. Utilizing a multimeter to test voltage and current at various points along the circuit offers insight into where discrepancies lie. If irregular readings occur, tracing back the connections from the panels to the inverter is essential. Understanding when to seek professional assistance shields against further potential damage and ensures the system’s long-term reliability. Therefore, proactive maintenance and checks are integral to sustaining performance.

WHAT SAFETY PRECAUTIONS SHOULD I CONSIDER WHEN WORKING WITH SOLAR PANELS?

When engaging in any tasks involving solar panels, safety should remain paramount. Begin by ensuring adequate personal protective equipment (PPE), such as gloves and eyewear, to shield against electrical hazards. Disconnecting the entire system from the grid and any batteries is crucial before performing any work on connections; this nullifies the risk of electric shock. Utilizing tools with insulated handles ensures additional protection. Additionally, checking environmental conditions prior to climbing onto roofs or handling panels safeguards against slips or falls. Awareness of local regulations involving heights or electrical systems facilitates compliance and safety planning. Adhering to these precautions not only protects the installer but also ensures the integrity of the solar system.

In summary, effectively connecting the lower port of flat panel solar panels necessitates a meticulous approach that includes identifying the specific port, selecting appropriate connectors, ensuring correct wiring, and securing connections properly. Recognizing the intricacies of these steps is significant for successfully harnessing solar energy. Proper installation, regular monitoring, and adherence to safety protocols lay the foundation for an efficient and safe solar panel system. By approaching each phase with diligence, individuals can maximize energy production while minimizing risks associated with solar technology.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-lower-port-of-flat-panel-solar-panel/