Connecting the lines under solar energy involves several steps that ensure the efficient function of a solar power system. 1. Understanding the basics of solar panel wiring is essential, 2. Proper safety measures must be observed throughout the installation, 3. Using the correct tools and materials is crucial for successful connections, 4. Routine maintenance and monitoring enhance performance.

1. UNDERSTANDING SOLAR PANEL WIRING

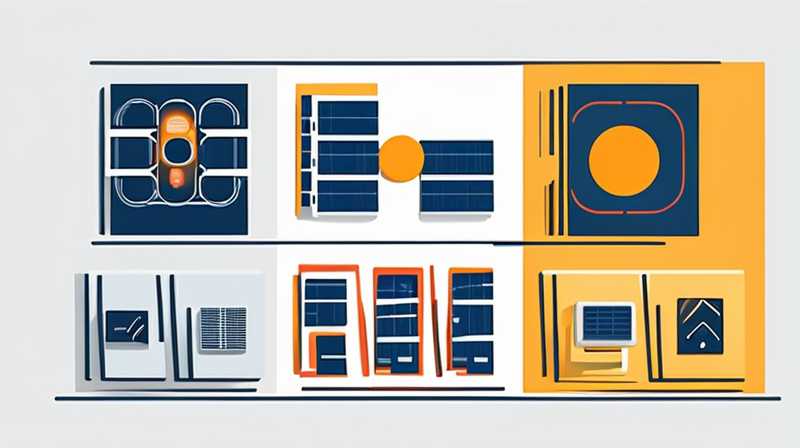

Wiring solar panels involves a fundamental assessment of both the series and parallel arrangements available. In a series connection, the positive terminal of one panel connects to the negative terminal of another, resulting in a cumulative increase in voltage. This technique is often preferred when higher voltages are required, such as in off-grid installations. For example, six 300-watt panels in series could produce 1,800 watts at a higher voltage level, suitable for specific inverter systems.

On the other hand, parallel connections link the positive terminals together and negative terminals together, preserving the voltage level while increasing the current. This option can be highly beneficial in situations where the panels may experience shading inconsistently; it allows other panels to continue functioning despite one unit’s decreased output. Understanding these configurations ensures that users can select the most suitable arrangement based on their energy needs and existing equipment.

2. SAFETY MEASURES IN INSTALLATION

The importance of safety cannot be overstated when working with solar energy systems, particularly when dealing with high-voltage systems. Standard practices should include wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and non-conductive footwear. Furthermore, turning off any connected devices and ensuring that the solar power system is disconnected during installation drastically reduces the risk of electric shock or accidents.

Additionally, ensuring a well-organized work environment minimizes the likelihood of slips, trips, and falls. All tools and materials should be stored securely, and any distractions should be minimized. It might also be sensible to have another qualified person present during installation to assist or provide help in emergencies. These precautions form an essential foundation for safely managing all installed solar power systems.

3. TOOLS AND MATERIALS NEEDED

A variety of tools and materials is vital for connecting solar panel lines effectively. Basic tools include wire strippers, crimpers, multimeters, and torque wrenches. These tools help ensure that the connections between solar panels are secure and effective. For example, wire strippers are necessary for removing the insulation from the wires, while multimeters can measure electrical voltage, current, and resistance to ensure proper functionality throughout the system.

When it comes to materials, selecting the appropriate gauge of wiring is crucial. The size of the wire should correspond to the power output required and the distance between the panels and the inverter or battery system. Common choices include copper and aluminum wires, both of which come in various sizes. Connector types, including MC4 connectors, are essential to complete secure connections between solar panels. Choosing high-quality materials ensures maximal efficiency and longevity for solar power installations, firmly establishing reliable power generation systems.

4. ROUTINE MAINTENANCE AND MONITORING

Monitoring and maintaining a solar energy system ensures that the installation provides the anticipated benefits throughout its lifespan. Regular checks, ideally every three to six months, should involve inspecting connections, cleaning solar panels, testing system outputs, and ensuring the inverter operates efficiently. Dust and debris can significantly reduce efficiency, requiring periodic cleaning, especially following storms or heavy pollution days.

In addition, performance monitoring tools can help analyze real-time data on energy production versus anticipated outputs. Monitoring can help identify underperformance due to shading, damage, or faulty equipment. If any discrepancies are detected, proactive steps can be taken to address potential failures, leading to increased efficiency and reliability over time. Well-maintained systems often yield many years of dependable service, allowing consumers to reap the maximum benefits from their solar investments.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE DIFFERENT TYPES OF SOLAR PANEL CONNECTIONS?

Different types of solar panel connections include series and parallel configurations. In series connections, panels are connected one after the other, amplifying voltage while keeping the current constant. This is beneficial for achieving higher voltages needed for certain systems, especially when the configuration matches the voltage requirements of inverters. Parallel connections, in contrast, keep the voltage level constant while increasing the system’s overall current capacity. This connection style is useful when optimizing energy production, especially in partially shaded conditions. Each configuration has its advantages, and selecting between them often depends on the specific needs of the solar power system and the hardware involved.

HOW CAN I ENSURE THE LONGEVITY OF MY SOLAR ENERGY SYSTEM?

To ensure the longevity of a solar energy system, consistent maintenance practices should be prioritized. Regular inspections should include checks on panel cleanliness, wiring connections integrity, and inverter performance. Keeping panels clean from dust, debris, and environmental buildup enhances efficiency, maximizing energy production over time. Using monitoring systems can also provide invaluable real-time data on performance, indicating when inspections or repairs should occur. Furthermore, choosing high-quality materials during the installation process significantly contributes to durability. Robust materials can withstand weather elements, resulting in fewer potential failures. Overall, a proactive approach to maintenance solidifies the investment’s long-term viability.

WHAT SAFETY PRECAUTIONS SHOULD I TAKE WHEN INSTALLING SOLAR PANELS?

Safety precautions during solar panel installation include wearing personal protective equipment, ensuring all equipment is off, and following proper installation procedures at all times. PPE should consist of insulated gloves, protective eyewear, and non-conductive footwear, protecting against potential electric shocks. Ensuring a safe work environment minimizes risks of falls or injuries, with tools organized and distractions kept to a minimum. It is crucial to familiarize oneself with local regulations and guidelines to operate safely concerning specific electrical codes. Having another qualified individual on hand can provide assistance and support, ultimately increasing safety and efficiency throughout the installation process.

Ensuring proper connections in a solar energy system is paramount for performance and longevity. The critical steps involve understanding wiring concepts, maintaining safety protocols, utilizing suitable tools and materials, and committing to ongoing monitoring and maintenance. Solar energy offers vast potential for sustainable, renewable power. Through diligent attention to detail in each stage of installation and care, users can fully enjoy the benefits of their solar investments. With diligent preparation and knowledgeable execution, solar energy systems can provide reliable service that aligns with environmental sustainability goals, showcasing the advantages of investing in clean energy. Family members and communities alike can benefit as these systems become a part of energy solutions globally. This commitment towards quality connections encapsulates a broader vision of a sustainable and efficient future, as renewable energy becomes an integral part of daily life.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-lines-under-solar-energy/