To successfully connect a hose to a solar pressure relief valve, follow these steps: 1. Ensure the system is depressurized and cool, 2. Select the appropriate hose diameter that matches the valve, 3. Utilize the right fittings to secure the hose to the valve, 4. Verify all connections for leaks. The first step is critical as it guarantees safety and prevents any accidents during the connection process. This thorough approach to hose attachment promotes efficiency and effectiveness in systems utilizing solar energy, as proper installation can impact the overall functioning of the pressure relief system.

- TOOLS AND MATERIALS REQUIRED

Establishing a successful connection between a hose and a solar pressure relief valve necessitates certain tools and materials. Among these, a suitable hose, appropriate fittings, and tools for securing the connections are essential. Specifically, it is crucial to ensure the hose meets the required diameter specifications. Standard sizes vary, but most solar systems require hoses with diameters ranging typically from half an inch to an inch. Using the exact specifications is vital to avoid future leaks or malfunctions.

In addition to the hose, fittings play a paramount role in establishing a reliable connection. These fittings must be made from durable materials, such as brass or stainless steel, which can withstand the solar system’s pressure and temperature fluctuations. Quality fittings not only enhance the overall performance of the system but also prolong its lifespan. Furthermore, gathering basic tools such as wrenches, screwdrivers, and, in some cases, teflon tape can streamline the process and ensure a leak-free setup.

- PREPARING THE VALVE FOR CONNECTION

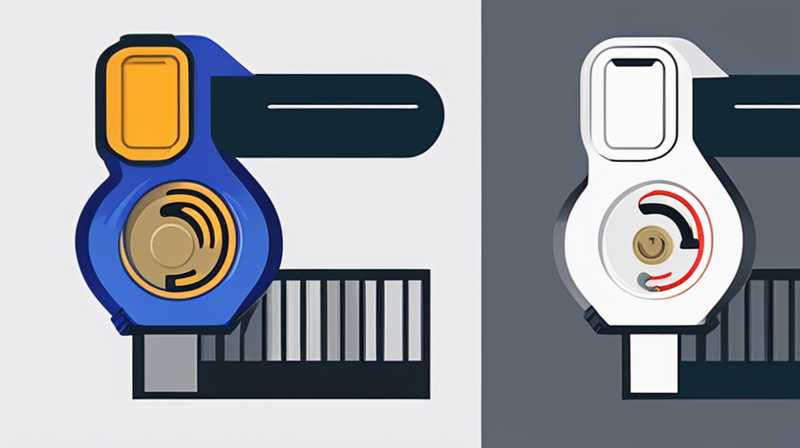

Prior to connecting the hose, preparing the solar pressure relief valve is imperative. The valve should be inspected to confirm it is functioning correctly. This involves examining the valve for any signs of wear, corrosion, or blockage that could impede the connection. Should any issues arise during the inspection, it may be necessary to replace or repair the valve prior to proceeding with the connection.

To prepare the valve, begin by wiping the area around the outlet where the hose will connect. This ensures a clean surface that minimizes the risk of debris or dirt entering the system. For further assurance, consider applying teflon tape to the threads of the valve if the valve design permits. This tape can serve as an additional layer of protection against potential leaks and is compatible with most plumbing systems. Following these preparatory steps places you in a solid position to connect the hose effectively.

- SELECTING THE APPROPRIATE HOSE

Choosing the right hose for connecting to the solar pressure relief valve is a fundamental aspect that demands attention. Materials and pressure ratings are paramount factors when making this decision. Common choices are reinforced rubber hoses or polyethylene options, each serving specific needs. Rubber hoses are generally more flexible, which can be beneficial in certain installation situations, while polyethylene hoses are often chosen for their durability and resistance to UV light.

Equally important is understanding the pressure rating of the hose. A hose that cannot withstand the operational pressure of the solar system could rupture, resulting in water leaks or system failure. Thus, when evaluating hoses, look for ones rated for high pressure—such as those designed for hydraulic systems—particularly if your solar application operates under substantial pressure. By investing time in selecting the appropriate hose, you ensure the system operates efficiently and safely.

- SECURING THE CONNECTION

When the hose and valve are prepared, the next stage involves properly securing their connection. Utilizing the appropriate fittings and tools is critical in this phase. Start by inserting one end of the hose into the valve outlet. Depending on the type of fitting utilized, either tighten the screws or utilize a wrench to secure the connection firmly. Applying excessive pressure is not recommended as it might damage the hose or valve threads.

Moreover, it is advisable to check the connection for leaks after securing it. This can be done by slowly turning the system on and observing for any leak signs. If the area around the connection remains dry, the attachment is secure. However, if leaks occur, it may be necessary to adjust the fitting or perhaps reapply some teflon tape for sealing. Ensuring a tight connection is key to maintaining the performance and reliability of the solar pressure relief system.

- MAINTENANCE OF CONNECTIONS

Post connection, the importance of maintenance cannot be overstated. Regular checks are needed to ensure the system remains leak-free and operates effectively. Periodically inspect the hose and fittings to identify any signs of wear or corrosion. Such proactive measures can prevent minor issues from escalating into significant water damage or pressure complications.

Furthermore, attention should be given to maintaining the solar pressure relief valve itself. Such maintenance may include periodic cleaning and inspections, particularly in areas with hard water or deposits. Keeping the valve in optimum working condition directly correlates with the longevity of the system. Devoting time to routine maintenance ensures that equipment operates efficiently and reduces the likelihood of disruptions.

FREQUENTLY ASKED QUESTIONS

- WHAT MATERIALS ARE BEST FOR A SOLAR PRESSURE RELIEF VALVE CONNECTION?

The best materials for a solar pressure relief valve connection include reinforced rubber hoses, stainless steel, and brass fittings. These materials can withstand varied pressures and temperatures inherent in solar systems. Rubber hoses provide flexibility, crucial for managing heating expansion and contraction, while stainless steel and brass fittings offer durability and resistance to corrosion, extending the lifespan of connections.

- HOW OFTEN SHOULD I CHECK FOR LEAKS IN MY SOLAR PRESSURE RELIEF SYSTEM?

Regular inspections of your solar pressure relief system should occur at least every six months. However, monthly checks are advisable, particularly after experiencing significant fluctuations in temperature or pressure. During these checks, look for signs of leaks around joints and fittings. Any visible water around these areas may indicate a need for repairs or preventive maintenance to preserve system efficiency.

- CAN I USE ANY HOSE FOR CONNECTION, OR ARE THERE SPECIFIC TYPES REQUIRED?

In most cases, choosing any hose for connection to a solar pressure relief valve is inadvisable. Each system’s requirements including diameter, pressure rating, and material compatibility must be considered. Using the incorrect type of hose can lead to leaks, kinks, and operational failures. Always refer to the manufacturer’s guidelines for recommended specifications to ensure proper function.

FINAL THOUGHTS

In summary, tackling the connection of a hose to a solar pressure relief valve demands precision and attention to detail. The importance of following the outlined procedures cannot be overstated as they ensure optimal performance and longevity of the solar system. A methodical approach covering aspects such as tool selection, hose characteristics, and general maintenance practices composes the foundation for successful connections. Emphasizing these principles allows for the smooth operation and extended lifespan of solar systems. By remaining diligent in regular check-ups and maintenance, one can mitigate risks associated with wear and potential system failures.

Moreover, the far-reaching benefits of effectively connecting hoses to solar pressure relief valves cannot be overlooked. Each element of the solar setup interconnects, and when one component operates efficiently, it positively impacts the entire system’s productivity. Commencing with correctly sized hoses and fittings will yield an unprecedented boost in reliability and safety. As consumers continue to adapt to solar technology, these foundational steps will empower users to maximize their system’s capabilities.

To achieve sustained performance from the solar pressure relief system, prioritizing each component’s selection and connection is essential. Understanding these expansive dynamics permits users to remain ahead of any possible complications. In the ever-evolving landscape of solar energy technology, proper installation techniques serve not only the present but also cultivate an infrastructure for ongoing advancements.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-hose-to-the-solar-pressure-relief-valve/