1. To connect the four wires of a solar floodlight, follow these steps: Determine the purpose of each wire, ensuring clean connections, 3. Use insulated connectors for safety, 4. Test the connections to confirm functionality. It is crucial to ensure that both positive and negative wires are accurately connected, as this process directly influences the effectiveness of the solar floodlight. Correct wiring not only enhances performance but also ensures longevity and reduces the risk of electrical hazards, establishing a reliable source of illumination.

CONNECTIONS IN SOLAR FLOODLIGHTS

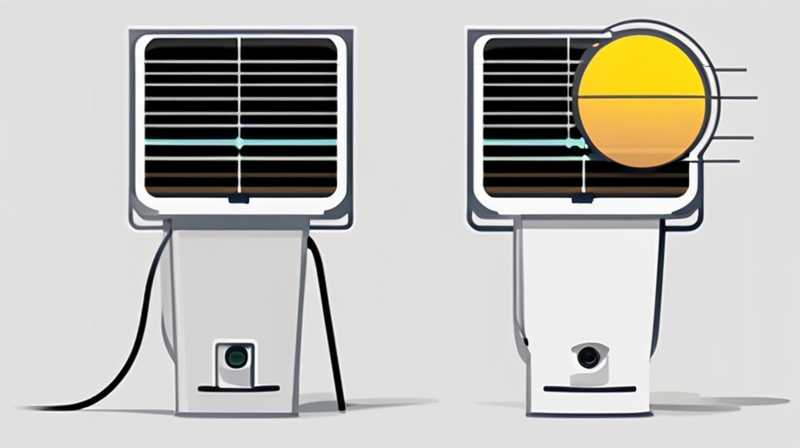

Solar floodlights operate on simple yet effective technology, making them an excellent choice for outdoor lighting. Understanding how to connect the four wires is pivotal for optimal functioning. The typical wires include positive, negative, and two others often associated with the light or sensor functions. Essential knowledge of these wires and proper connection techniques leads to enhanced light performance and prolonged lifespan. Knowledge of the wiring diagram specific to your floodlight model will also aid in achieving a solid electrical connection.

The utility of solar energy has surged in popularity due to rising energy costs and environmental concerns. Floodlights powered by solar energy are a sustainable solution, utilizing sunlight during the day and converting it efficiently into light during the night. The connection of the wires plays a significant role in how well the solar charge characteristic is maintained, directly affecting the battery recharge and discharge cycles. Hence, understanding how to connect the wires is crucial for maximizing the efficiency and reliability of solar floodlights.

1. IDENTIFICATION OF WIRES

To begin, familiarizing oneself with the wiring system of solar floodlights is the first step in this process. Typically, four wires are involved: positive (+), negative (-), light control, and battery cable. Each wire has a distinctive function. The positive wire connects to the solar panel, allowing current flow, while the negative wire serves as a return path for the electricity. In most models, the light control wire enables automatic operation according to ambient light levels, effectively turning the light on or off as needed. Lastly, the battery cable links the charge controller to the battery, managing energy storage efficiently.

Identifying and recognizing the wires is not enough; one must also understand their purpose thoroughly. The positive wire is crucial in conducting electricity to the load, while the negative wire completes the circuit; hence, interchanging them can cause malfunction or damage. The light control wire typically can vary in color and function, so reviewing the manufacturer’s manual for specific instructions is essential. Ensuring an exact match and connection of the corresponding wires improves functionality and operational efficiency.

2. PREPARATION FOR WIRING

Once the wires are identified, the next critical aspect involves preparation for the connection. One must gather necessary tools and materials, including wire strippers, insulated connectors, electrical tape, and possibly a multimeter for testing connectivity. Before proceeding, it’s essential to turn off the electrical input to prevent accidents while working on the system. Utilizing wire strippers appropriately cleans the wire ends for better connectivity, preventing corroded or damaged points that can inhibit functionality.

Prior to making any connections, one must test all components using a multimeter. Checking for continuity in the wires ensures there are no breaks that could affect performance. Knowing that each connection point is secure is vital for solar floodlights as they are often placed in outdoor environments vulnerable to weather conditions. Ensuring robust connections can effectively reduce wear due to environmental stress and extend the lifespan of the fixture as a whole, ensuring sustained illumination when needed.

3. CONNECTING THE WIRES

With components prepped and tested, the actual connection phase can commence. Begin by connecting the positive wire from the solar panel to the positive input on the charge controller. Following that, attach the negative wire from the solar panel to the charge controller’s negative input. This sets up the primary power circuit, allowing direct energy flow from the solar panel to the controller. Ensuring solid and tight connections at these points helps prevent loss of energy that can occur with loose fittings.

Next in line, connect the battery cable, usually consisting of two wires, to both the positive terminal of the battery and the corresponding output on the charge controller. In this activity, attention to detail is essential; improperly connected wires can lead to battery overcharging or failure, risking the entire setup. Ensure positive is connected to positive and negative to negative. Applying insulated connectors and using electrical tape can further enhance security against any connection fallout, especially under adverse weather conditions.

4. TESTING AND CONFIRMATION

Upon connecting all wires, the final testing ensures that all components function as intended. Utilize a multimeter to check for voltage at various points in the system. Confirming that the solar panel is effectively charging the battery and that the light control wire responds appropriately to daylight changes is essential. Observing the light’s performance post-connection for a few evenings will also help ascertain that connections are made correctly and functioning as they should.

Should any discrepancies arise during testing, revisit each connection point meticulously. Assess if wires were connected to incorrect terminals or if connectors are excessively loose. Correcting these issues promptly prevents long-term damage to the system and supports optimal operational efficacy. Proper testing guarantees enhanced peace of mind, establishing confidence in the installation and ensuring the system remains robust for years.

5. MAINTENANCE OF CONNECTIONS

While the focus often resides on initial setups, routine maintenance of wired connections plays a critical role in the overall longevity of solar floodlights. Over time, environmental exposure, vibrations, and temperature fluctuations may loosen wire connections. Regularly inspecting all terminals to ensure secure connections helps mitigate risks associated with power failure or lights not functioning correctly.

Additionally, during maintenance checks, one can monitor the integrity of the wires. If any signs of damage, like fraying or corrosion, are visible, it strengthens the case for replacing those wires immediately. This proactive approach aids in maintaining an effective solar lighting system, ensuring continued performance for outdoor areas and reducing long-term expenses associated with repairs and replacements.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE FUNCTION OF EACH WIRE IN A SOLAR FLOODLIGHT?

The functional roles of the wires in a solar floodlight are vital for their performance. The positive wire connects directly to the solar panel, channeling energy collected from sunlight to various devices. In contrast, the negative wire acts as a return path, enabling the current to complete the circuit back to the panel and preventing the buildup of excess electricity. The light control wire is designed to operate the lighting mechanism automatically based on ambient light levels, allowing for convenient usage without manual intervention. Lastly, the battery cable facilitates energy transfer between the solar panel and the battery storage, enabling energy utilization even during non-sunny periods.

Understanding these roles elucidates how proper wiring affects the functionality of solar floodlights. Misconnections or faulty wire handling can disrupt the energy flow and thus compromise the light’s effectiveness. In proper configurations, each wire serves a unique role, contributing to the overall system’s efficiency. Regular checks and maintenance of connections reinforce the system’s reliability while informing users about the necessity of these electrical components.

HOW CAN I ENSURE MY SOLAR FLOODLIGHT WORKS PROPERLY?

To guarantee that your solar floodlight operates correctly, several measures must be upheld throughout the installation and usage procedures. Firstly, selecting a quality device compatible with the intended environment is essential. A well-constructed solar floodlight will typically feature robust components designed to handle various weather conditions, boosting reliability over time. Secondly, proper installation is critical; an accurate connection of all wires ensures efficient energy transfer and functionality.

Regular maintenance is another cornerstone of keeping your solar floodlight in optimal working condition. Periodically inspect the wiring and connections for any signs of wear or damage, fixing issues immediately to prevent their escalation. Ensure the solar panel is clean and free from obstructions, as dirt or debris can significantly reduce charging efficiency. Lastly, observe the light’s performance frequently and monitor battery levels. If the light does not operate as expected, revisiting the connection steps or consulting a professional could yield positive results.

WHAT TO DO IF MY SOLAR FLOODLIGHT DOES NOT TURN ON?

If your solar floodlight exhibits non-functionality, a systematic troubleshooting approach will help identify and resolve the issue. Start by checking the connections to ensure all wires are correctly attached and terminals are secure. Loose or reversed connections often lead to performance challenges. If connections are intact, evaluate the solar panel. Ensure it is unobstructed and clean; dirt or shading can hinder solar energy absorption, limiting the power available to operate the light.

Next, inspect the battery to determine if it has maintained sufficient charge. Utilizing a multimeter can provide detailed insights into voltage levels and overall battery health. If the battery appears faulty, it may require replacement. Lastly, consult the owner’s manual for specific troubleshooting tips linked to the model. This resource will guide the user through common issues and solutions while facilitating further understanding about particular nuances of the solar floodlight design.

SOLAR FLOODLIGHT CONNECTIONS ARE CRUCIAL FOR EFFECTIVE OPERATION. A THOROUGH UNDERSTANDING OF THE WIRING PROCESS CONTRIBUTES SIGNIFICANTLY TO THE LIGHT’S EFFICIENCY AND LONGEVITY. BY CLEARLY IDENTIFYING EACH WIRE’S FUNCTION AND ENSURING PROPER CONNECTIONS, USERS CAN MAXIMIZE PERFORMANCE WHILE MINIMIZING RISK OF DAMAGE. REGULAR MAINTENANCE AND TESTING HELP PRESERVE FUNCTIONALITY OVER TIME, INSTILLING CONFIDENCE IN SOLAR LIGHTING SYSTEMS. AS SOLAR ENERGY CONTINUES TO GAIN TRACTION, MASTERING THESE CONNECTION STEPS BECOMES INCREASINGLY IMPORTANT FOR END USERS LOOKING TO CAPITALIZE ON SUSTAINABLE TECHNOLOGIES.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-four-wires-of-solar-floodlight/