Connecting the float to the solar solenoid valve requires careful attention to detail to ensure a functional irrigation system. 1. Identify the components involved, including the float switch, solar solenoid valve, and necessary wiring. 2. Select the appropriate location for installation, ensuring that the float operates smoothly without obstruction. 3. Utilize reliable connectors and cables designed for outdoor use to withstand environmental factors. 4. Test the system after installation for optimal operation, checking for leaks, electrical issues, and responsiveness of the valve.

DETAILED EXPLANATION OF COMPONENTS AND FUNCTIONALITY

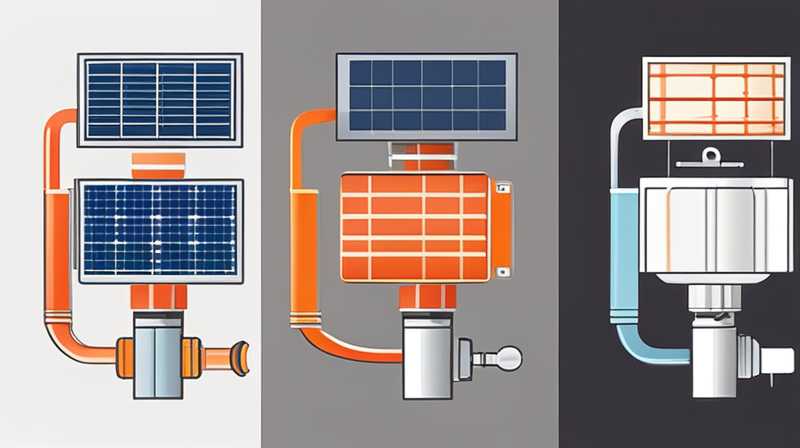

The integration of a float switch with a solar solenoid valve is a pivotal aspect of automation in irrigation systems, particularly in areas where water conservation is paramount. At the heart of this assembly lies the float switch, which serves as a pivotal mechanism in sensing water levels within a reservoir or a tank. Understanding its operational mechanism helps in ensuring a seamless connection. The float switch operates using a simple buoyancy principle, activating or deactivating the solenoid valve based on the pre-determined water levels.

This solenoid valve acts as an electromechanical device, using electrical signals to control water flow. When the float switch is engaged due to low water levels, it sends a signal to the solenoid to open, allowing water to flow, while excess water causes the float to rise and close the valve, preventing overflow. This automated regulation conserves water and ensures efficiency.

SELECTING AN APPROPRIATE LOCATION FOR ASSEMBLY

Choosing the right location for both the float and the solar solenoid valve is crucial for achieving optimal performance. The site should allow the float to move freely without obstruction, ensuring that it accurately reflects the water levels. Factors such as the accessibility for maintenance, sunlight exposure for solar panels, and proximity to water sources play a role in this selection process.

Furthermore, consider environmental conditions that could affect the system’s functionality. Areas with high debris accumulation, for instance, may obstruct the float’s operation. Therefore, maintaining clear pathways for the float leads to enhanced operational efficiency, reducing the chances of malfunction that could disrupt the entire irrigation process.

INSTALLATION AND CONNECTORS

The installation phase of linking the float to the solar solenoid valve involves utilizing quality connectors and wiring capable of handling outdoor conditions. This typically includes waterproof connectors that provide secure connections, preventing corrosion due to moisture exposure. It’s vital to choose the correct gauge of wire capable of ensuring minimal voltage drop, which can adversely affect the performance of electrical components.

Ensure that all connections are made according to the manufacturer’s guidelines. Incorrect wiring can lead to operational failures, creating leaks or resulting in the float not activating the solenoid valve as intended. Beginning the installation with thorough planning and correctly reading the instruction manuals will offer a smoother assembly experience.

TESTING AND TROUBLESHOOTING THE SYSTEM

After the installation is complete, rigorous testing of the system is essential to verify successful implementation. Checking for leaks, loose connections, and responsiveness of the float switch and solenoid valve ensures that the system operates correctly. Start by manually engaging the float to see if the solenoid valve responds as anticipated.

If the system does not perform as expected, reviewing each connection, examining the float’s movement, and ensuring that no obstructions exist is necessary. Debugging potential issues is critical; a thorough inspection often reveals minor errors that can be rectified to restore functionality.

MAINTENANCE OF THE SYSTEM

Long-term maintenance of the float and solar solenoid valve system is vital for continued operation and efficiency. Regular inspections can prevent major breakdowns and prolong the lifespan of the system. Look for signs of wear on the float and check the solenoid valve for any signs of blockage or malfunction.

Cleaning the float will help prevent algae buildup that may hinder its operation, while periodically testing electrical connections will ensure robust performance. Investing time in scheduled maintenance can save significant resources and enhance efficient irrigation, ultimately conserving water in agricultural practices or personal gardens.

FREQUENTLY ASKED QUESTIONS

WHAT IS A FLOAT SWITCH AND HOW DOES IT WORK?

A float switch is a device used to detect the level of liquid within a tank, well, or other container. It operates on a simple principle of buoyancy, where a buoyant object (the float) rises and falls with changing liquid levels. When the float reaches a certain height, it activates or deactivates a switch connected to a solenoid valve, allowing or stopping the flow of liquid. Float switches are commonly used in various applications, including irrigation systems, sump pumps, and water tanks, to automate the control of water levels. Different types of float switches are available, such as mechanical and electronic, each suited for specific applications. When integrating a float switch with a solar solenoid valve, selecting a reliable type is crucial to ensure the efficiency and reliability of the irrigation system while adhering to safety standards.

HOW DO I CHOOSE THE RIGHT SOLENOID VALVE FOR MY IRRIGATION SYSTEM?

Choosing the correct solenoid valve for your irrigation system involves several considerations. The first step is to determine the intended application, bottom line pressure requirements, and type of fluid being controlled. Size and flow rate of the valve are critical, as an undersized valve may lead to insufficient water delivery, while an oversized valve can cause pressure fluctuations. Additionally, you’ll want to consider the type of activation — whether it is normally open or normally closed — based on how you wish the system to operate with the float switch. The materials of construction are also essential, as they should be compatible with water quality to prevent corrosion or degradation over time. Consulting with professionals and taking precise measurements can assist in making informed decisions regarding the solenoid valve for your specific irrigation needs.

HOW OFTEN SHOULD I TEST MY FLOAT SWITCH AND SOLENOID VALVE SYSTEM?

Regular testing of the float switch and solenoid valve is recommended to guarantee optimal performance. A proactive maintenance schedule may include monthly checks, especially during peak usage seasons, such as spring and summer when irrigation demands are high. Testing should involve manually raising and lowering the float to confirm that the solenoid valve responds accurately and effectively. Pay attention for any signs of wear, leaks, or potential blockages within the valve. In regions with fluctuating weather conditions, attending to the system after heavy rains or storms is prudent as debris can cause obstructions that hamper functionality. Overall, scheduling routine assessments of these critical components not only promotes efficiency but also significantly reduces the risk of sudden breakdowns during critical periods.

SYSTEM FUNCTIONALITY AND EFFICIENCY

Ultimately, the harmonious loop of water regulation through the connection of the float and solar solenoid valve emerges as a cornerstone for irrigation efficiency. Employing these automated links reduces labor, ensures precise water application, and facilitates environmental stewardship by minimizing waste. Rising concerns over water scarcity underscore the importance of such systems, where each drop is valued and utilized wisely.

Thus, for anyone contemplating the connection of a float to a solar solenoid valve, comprehending the intricacies of assembly, operational mechanisms, and ongoing maintenance forms the foundation for successful water management. Diligence in setup, regularized testing, and appropriate selections of components intertwine to create a sustainable irrigation ecosystem. In a world striving for efficiency, embracing these automated technologies allows for a more consistent approach that honors both the earth’s resources and the gardener’s ambitions.

By ensuring adherence to these comprehensive guidelines, individuals can construct a reliable irrigation system that echoes the principles of sustainability while meeting various agricultural needs. This interconnected approach, also standing as a testament to innovation and proactive resource management, embodies the spirit of modern water conservation efforts.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-float-to-the-solar-solenoid-valve/