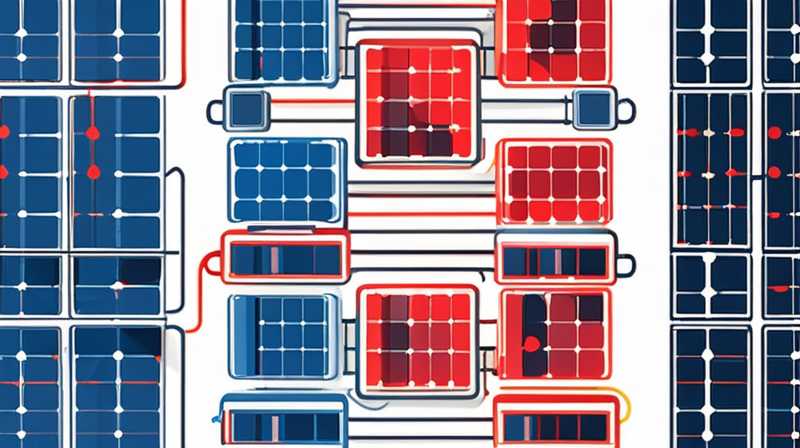

To connect the blue and red wires of solar panels, one must follow specific procedures to ensure proper functioning and safety. 1. Identify the positive and negative wires, 2. Connect the red wire to the positive terminal, 3. Connect the blue wire to the negative terminal, 4. Insulate the connections properly. The blue wire typically indicates the negative connection, while the red wire signifies the positive connection. Properly connecting these wires is critical because incorrect connections could lead to device failure or electrical hazards. Attention to detail and adherence to safety protocols will guarantee an effective installation process.

1. UNDERSTANDING SOLAR PANEL WIRING

Solar panels operate by converting sunlight into electrical energy. To grasp the intricacies of connecting the blue and red wires, one must recognize how solar panels function. They consist of photovoltaic cells that absorb sunlight and generate direct current (DC) electricity. The electricity generated can be utilized for immediate energy needs or stored in batteries for later use. Wiring plays a crucial role in ensuring that this generated electricity flows effectively to inverters, batteries, or direct loads.

The wiring system is composed of various components, and each wire must be handled correctly for optimal performance. The red and blue wires signify different polarities; typically, red indicates the positive terminal while blue denotes the negative terminal. When connecting these wires, it is essential to ensure that they are linked to their corresponding terminals, as incorrect connections can lead to short circuits or damage to the solar panel system.

2. SAFETY PRECAUTIONS

Before initiating any wiring endeavor, especially with solar energy systems, it is vital to prioritize safety. The electrical components involved in solar energy systems carry risks that should be addressed with utmost seriousness. Electrical shocks, fire hazards, and equipment damage can occur if safety protocols are disregarded. Furthermore, working with solar panels involves exposure to sunlight, which could lead to physical injuries or heat-related issues.

To mitigate risks, one should wear appropriate safety gear, such as gloves and safety glasses. Moreover, it is advised to work during cooler parts of the day to avoid overheating. Disconnecting all power sources before beginning installation is one of the most critical precautions. This ensures that the system is not live and eliminates the possibility of accidental shocks while handling the wires.

3. IDENTIFYING TERMINAL CONNECTIONS

Before any connections are made, identifying the correct terminals on the solar panel and associated components is crucial. The typical configuration of solar panels includes clear labeling to assist in proper identification. Usually, the positive terminal is marked with a ‘+’ sign, while the negative terminal is denoted with a ‘-’ symbol. Understanding these markings simplifies the wiring process and enhances safety.

To begin, one should visually inspect both the solar panel and the connecting wires. Confirm that the red wire connects to the positive terminal marked ‘+’, while the blue wire links with the negative terminal marked ‘-’. This clear differentiation helps in organizing connections and maintaining system integrity. Additionally, refer to the user manual or guidelines provided by manufacturers, as variations may exist between different models and brands.

4. CONNECTING THE RED WIRE

The first step in wiring involves connecting the red wire to the designated positive terminal. This step is paramount since misconnection could result in system failure or danger. Using a wire stripper, carefully remove the insulation from the red wire’s end, exposing enough copper to establish a secure connection. A terminal connector crimp tool may be employed to attach a connector to the red wire securely.

When connecting the red wire, ensure a firm and stable fit to facilitate optimal conductivity. After securing the red wire to the positive terminal, it’s prudent to gently tug on the wire to guarantee that it is tightly attached. This minimal resistance ensures that the electrical flow is not hampered. Once connected, visually inspect the connection for any visible issues, ensuring no exposed metal is present that could lead to shorts.

5. CONNECTING THE BLUE WIRE

Upon connecting the red wire, the next crucial action is to connect the blue wire to the negative terminal. This connection should follow similar protocols established for the red wire to ensure a seamless electrical flow. Strip the blue wire’s end for adequate coverage at the terminal connection. It is essential to utilize terminal connectors or lugs compatible with the wire gauge being used.

After attaching the blue wire to the negative terminal, double-check the connection stability and security, ensuring all exposure to metal is minimized. Proper soldering techniques or the use of heat shrink tubing can further safeguard against environmental factors that may affect wire integrity. Once the blue wire has been securely connected, check the overall setup to ensure both wires are connected without any tension or potential for disconnection.

6. INSULATION AND PROTECTION

With both wires securely attached to their respective terminals, the next phase involves insulating the connections. Proper insulation is crucial to safeguard against moisture, damaging elements, and accidental contact. Electrical tape or heat shrink tubing can be utilized to cover the exposed metal connections, significantly reducing the risk of short circuits or shocks.

Ensure the insulation covers the entirety of the exposed wires, creating a barrier against external environmental factors. This protection improves the longevity of the connections and enhances overall system security. In addition to electrical tape, silicone sealant can be applied around the connections to provide further protection from moisture, ensuring that the wiring remains robust and secure over time.

7. FINAL CHECKS AND TROUBLESHOOTING

Once all connections are made and insulated, performing a series of checks ensures that everything is in order before energizing the solar panel system. Conduct a comprehensive inspection of the entire wiring setup and associated components to confirm all connections are established correctly and securely. Look for any signs of wear, corrosion, or damage that may affect performance.

If, during inspection, any irregularities are noted with the connections, immediate rectification is necessary. Common troubleshooting steps include rechecking the integrity of wire connections, ensuring all insulation is secure, and confirming the polarity of the connections matches the intended design. These final screens enable an assurance that the system is prepared for operation, minimizing the risks of failures when powered on.

8. UNDERSTANDING SYSTEM FUNCTIONING

Upon connection and insulation, it would be prudent to understand how the interconnected parts function. When sunlight strikes the photovoltaic cells, electrons are dislodged, producing electricity that flows through the connected wires to power devices or charge batteries. The effectiveness of this conversion depends significantly on the connections made; hence, every aspect of wiring must be diligently considered.

Regular monitoring of the system’s performance is essential to identify potential problems early. Observing voltage outputs and power generation levels can help detect malfunctions in the connections. Utilizing tools like multimeters and voltage testers allows precise analysis of the system’s functioning, ensuring it delivers its intended electrical output efficiently.

9. MAINTENANCE REQUIREMENTS

To sustain the system’s effectiveness over time, regular maintenance of the wiring connections and associated components is essential. Visual inspections should be conducted periodically to check for wear or corrosion and to ensure insulation remains intact. Additionally, keeping the solar panels clean will enhance their performance, allowing them to capture sunlight more efficiently.

It is worthwhile to develop a maintenance schedule to perform these evaluations. Regular maintenance not only prolongs the lifespan of the wiring but also promotes optimal functioning of the entire solar system. A well-maintained system significantly reduces the risk of unexpected failures or hazards.

10. ENCOURAGING CONTINUED LEARNING

Finally, as technology advances, understanding and utilizing new methods and materials in solar panel installation and maintenance is essential. Engaging with current literature and technological advancements enhances one’s ability to perform successful installations and encourages innovation in personal or community solar projects. Online resources, forums, and industry publications provide valuable insights and updates that keep individuals informed.

Further learning about solar energy systems can open up opportunities for sustainable practices and energy conservation within communities. Collaborating with experts or participating in workshops can lead to improved skills and knowledge, allowing individuals to contribute positively to the growth and effectiveness of renewable energy technologies.

FREQUENTLY ASKED QUESTIONS

WHAT TOOLS DO I NEED FOR WIRING SOLAR PANELS?

Proper tools are essential for an efficient solar panel installation. When wiring solar panels, a variety of instruments can enhance both safety and effectiveness. Commonly needed tools include wire strippers to remove insulation from copper wires, crimping tools to attach connectors securely to stripped wires, and screwdrivers for obtaining tight terminal connections. Further, voltage testers and multimeters enable precise measurement of connections, ensuring safety before activating the system.

In addition to the basic tools mentioned, having electrical tape or heat shrink tubing is critical for insulation purposes. Insulating materials safeguard against environmental damage and electrical hazards. Depending on the complexity of the installation, one may also need additional tools such as a drill for mounting panels and protective gear, including gloves and safety glasses.

HOW CAN I ENSURE MY SOLAR CONNECTIONS ARE SAFE?

Safety is paramount when connecting solar panel wires. To ensure secure connections, one must adhere to established electrical standards and apply thorough verification checks before energizing the system. First and foremost, disconnecting all power before commencing wiring is essential to prevent accidental shocks. Once the connections are made, meticulous inspection of polarities must be completed, verifying the red wire connects to the positive terminal, while the blue wire links to the negative.

Further safety protocols encompass using appropriate insulating materials for exposed wires, ensuring no metal contacts are left unattended. Regular maintenance checks to identify wear and tear, corrosion, or component damage are key to sustaining the overall safety of the system. Finally, educating oneself on electrical hazards and seeking guidance from professionals when needed ensures a high level of safety.

WHAT COMMON MISTAKES SHOULD I AVOID WHEN CONNECTING SOLAR PANELS?

Several crucial mistakes can be made during solar panel connections, which can lead to inefficiency or hazards. One of the most significant errors is interchanging the polarity of the wires, which can result in damaging equipment. It is vital to clearly identify the positive and negative terminals before commencing work, ensuring red connects to positive and blue to negative.

Another frequent mistake is inadequate insulation of wire connections, which can expose bare metal and create hazard risks. Properly insulating all connections with electrical tape or heat shrink tubing is essential for safeguarding against environmental and electrical threats. Lastly, overlooking regular maintenance checks can lead to undetected issues that compromise the system’s integrity, making it critical to develop a strategy for ongoing assessment and care.

Final thoughts on the distinct process of connecting solar panel wires underscore the importance of precision, understanding, and safety. Successfully achieving proper wiring requires diligence in following protocols and maintaining awareness of safety measures to guarantee functionality and longevity. Thoroughly evaluating one’s methods and readiness to adapt to advances in solar technology is invaluable for enhancing both individual systems and broader energy practices. Mastering these skills not only fosters personal growth but contributes positively to sustainable energy initiatives, making it imperative for practitioners to engage in lifelong learning and proactive involvement within the renewable energy community.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-blue-and-red-wires-of-solar-panels/