To successfully connect a ball valve to a solar integrated pipe, follow a systematic approach that ensures proper alignment, sealing, and functionality. 1. Proper alignment is crucial; 2. Use the right tools for tightening; 3. Select appropriate fittings; 4. Test for leaks after installation. When connecting components like ball valves to solar integrated pipes, the importance of proper sealing cannot be overstated. A well-sealed connection minimizes the risk of leaks and inefficiencies in the system, which is essential for maintaining the effectiveness of solar heating systems.

1. UNDERSTANDING THE COMPONENTS INVOLVED

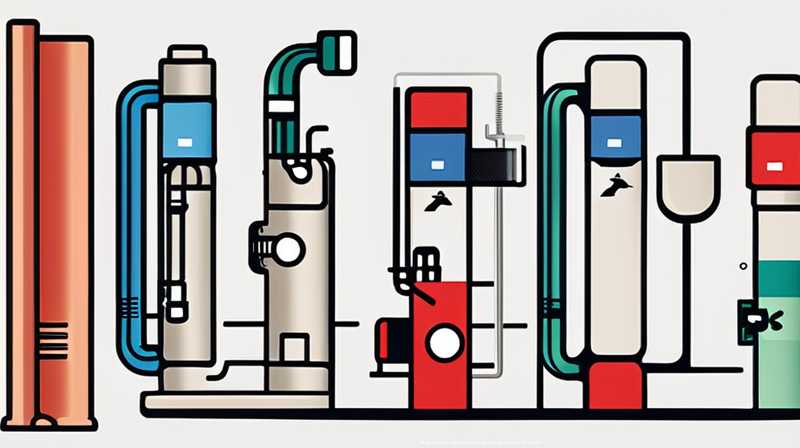

Understanding the components before attempting a connection is essential for a successful installation. The ball valve is a mechanical device that allows or obstructs the flow of fluids. Typically made from materials such as brass, stainless steel, or PVC, these valves feature a spherical disc with a hole in the center. When the ball is rotated, the passage aligns with the flow direction, allowing fluids to pass through. Conversely, when it is perpendicular, the flow is halted. Thus, its functionality is simple yet effective, offering a reliable way to manage fluid passage in solar applications.

Solar integrated pipes are specially designed for solar heating systems, generally crafted from durable materials like copper or PEX. These pipes can withstand the high temperatures generated during solar energy processes, making them ideal for such applications. The integration aspect implies that these pipes feature additional components that enhance functionality, such as insulation layers that promote energy efficiency. Understanding how these items work independently is essential for grasping how they will function cohesively when connected.

2. PREPARING FOR INSTALLATION

Preparation plays a vital role in the installation process. Start by gathering all necessary tools and materials. In addition to the ball valve and solar integrated pipe, you will require Teflon tape, a wrench, and potentially additional fittings depending on your specific setup. Having all these components ready saves time and reduces the likelihood of errors during the connection process.

Before installation, also ensure that all surfaces are clean and free from debris. Any foreign material can compromise the integrity of the seal, leading to leaks or system inefficiencies. Use a clean rag to wipe down the ends of the pipes and the ball valve. Checking for any damage or imperfections should also be part of the preparatory steps. Any issues found at this stage can save you considerable time and resources, making it a critical phase in the process of connecting the ball valve to the solar integrated pipe.

3. CONNECTING THE BALL VALVE TO THE SOLAR INTEGRATED PIPE

Now that preparations are complete, the actual connection can be undertaken. Begin by applying Teflon tape to the threads on the ball valve. This tape serves as a sealant to prevent leaks in threaded connections. Ensure you wrap the tape in the direction of the threads, starting from the end of the valve and working your way towards the body. Proper application of Teflon tape is essential, as it guarantees a snug fit when you screw the valve onto the pipe.

Next, fit the ball valve onto the solar integrated pipe. If your installation requires fittings, attach them after ensuring the threads are adequately wrapped in Teflon tape. Use the wrench to tighten the connections, ensuring that excessive force is avoided, as over-tightening can cause damage. A secure connection is essential, but it should also provide the flexibility necessary to allow for any expansion or contraction caused by temperature changes in the surrounding environment.

4. TESTING FOR LEAKS AND FINAL ADJUSTMENTS

After the ball valve is connected to the solar integrated pipe, it becomes crucial to test for leaks to ensure the assembly functions as intended. Turn on the system and observe the connections closely for any signs of fluid escaping. If any leaks are detected, the joint will need to be tightened, or, if necessary, disassembled and re-sealed. Taking immediate action helps prevent more significant issues down the line, especially in systems where liquid is under pressure.

In addition to leak testing, it’s advisable to monitor the overall function of the assembly. Observe whether the ball valve allows for smooth flow regulation and whether it opens and closes as expected. This can be evaluated by adjusting the valve and noting any resistance or unusual sounds that could indicate a potential malfunction. If everything operates smoothly, the installation can be considered successful, laying the foundation for efficient solar system performance.

FAQs

WHAT TOOLS DO I NEED TO CONNECT A BALL VALVE TO A SOLAR INTEGRATED PIPE?

To connect a ball valve to a solar integrated pipe, the essential toolkit includes a wrench, Teflon tape, and possibly additional fittings. The wrench is crucial for tightening the connections without overdoing it, while Teflon tape ensures a proper seal. If there are specific size discrepancies between the valve and pipe, fittings may be necessary to create a compatible connection. Always ensure that you have the correct tools on hand before proceeding with the installation, as this will simplify the process and minimize errors.

HOW CAN I IDENTIFY A LEAK IN THE CONNECTION?

Identifying leaks in your connection involves visual inspection and observation during system operation. Start by closely examining the joints where the ball valve meets the solar integrated pipe for any signs of moisture or water drip. During system operation, look and listen for any unusual sounds during fluid passage, which could indicate a poor seal. If you suspect a leak, performing a pressure test can provide further insights into the integrity of the connections. Utilize cotton or paper towels to detect any emerging water around the connections, facilitating early problem identification.

IS IT NECESSARY TO USE Teflon TAPE EVERY TIME I INSTALL A BALL VALVE?

Using Teflon tape is generally recommended to ensure proper sealing in threaded connections. While some modern fittings are designed to create a seal without tape, employing Teflon tape can provide an additional layer of protection against leaks. If the connection type typically requires tape for sealing, it is advisable always to use it for the best results. Proper application of Teflon tape increases the longevity of the connection and enhances the overall efficiency of the piping system, particularly in systems that handle pressurized fluids.

The connection of a ball valve to a solar integrated pipe embodies a blend of technical skill and knowledge. Careful attention during preparation, installation, and testing crucially enhances the reliability and efficiency of solar heating systems. Ensure that preparations encompass all required tools and components, as this facilitates a seamless connection experience. Understanding the components involved aids in anticipating and troubleshooting potential issues during installation. Securing a tight fit with the aid of Teflon tape and maintaining proper alignment eliminates common pitfalls associated with such connections. Always prioritize leak testing and monitor functionality, as these steps will help verify the integrity of the installation. Investing time in this procedure will not only preserve the fluid transfer efficiency but will also contribute to the overall performance of solar system applications, leading to enhanced energy conservation and user satisfaction. As solar energy gains dominance in promoting sustainability, mastering plumbing connections becomes increasingly important for professionals in the field, thereby ensuring the longevity and effectiveness of such systems.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-ball-valve-to-the-solar-integrated-pipe/