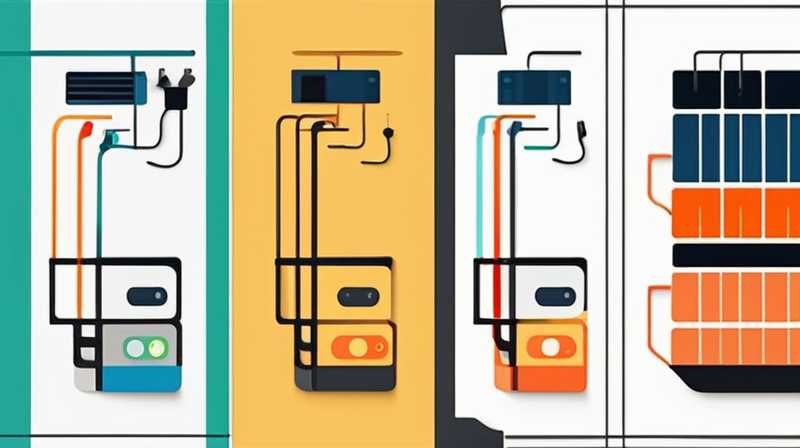

To connect the four wires of a solar panel, follow these key steps: 1. Identify wire functions, 2. Connect positive to positive, 3. Connect negative to negative, 4. Secure connections properly. Understanding wire functions is of utmost importance as solar panels typically have two positive (red) and two negative (black) wires: positive wires connect to a charge controller, while negative wires serve ground connections. Taking time to ensure secure and insulated connections can prevent potential short circuits or other issues that could hinder efficiency. Each connection should be examined for the integrity of the joint as well as weatherproofing to withstand environmental changes.

1. UNDERSTANDING WIRE FUNCTIONS

To successfully connect the four wires of a solar panel, an initial grasp of their specific functions is essential. Each wire plays a vital part in the photovoltaic system’s operation. Usually, solar panels possess two positive and two negative wires. The positive wires are typically identified by their red insulation, while the negative wires are usually insulated in black.

The positive wires are responsible for transmitting the electrical output toward the next components, often a charge controller or battery storage system. Conversely, the negative wires serve as return conductors, creating pathways for electrical flow back to the solar panel’s ground system. Understanding this fundamental role assists with effective and safe connections.

Choosing the correct orientation in which to connect the wires becomes crucial. Ensuring that positive wires are joined directly to their respective counterparts without mixing them with the negative wires is the bedrock for developing a functional solar energy system. Each connection must be both strong and secure, as loose fittings can introduce resistive losses that negatively impact energy efficiency.

2. CONNECTING POSITIVE WIRES

Once the wires have been correctly identified, connecting the positive wires is the next logical step. Here, thorough attention must be paid to ensure that soldering or crimping, whichever junction method is chosen, is executed correctly. If soldering, it is crucial to pre-tin the wire ends before bringing them together, promoting enhanced electrical conductivity.

Strong connections between the solar panel’s positive wires and the charge controller or battery yield optimal energy distribution. If a charge controller is utilized, the charge controller’s positive terminal should receive input directly from the solar panel’s positive wire. This precision in connecting enhances both voltage performance and increases energy capture efficiency.

Furthermore, verifying polarity is paramount throughout. A connection mix-up can result in damaged equipment or decreased performance. Conducting a visual inspection after initial connections provides reassurance that all configurations align with their designated roles in the overall system setup. The consequences of failing to accurately connect can extend beyond simple poor functionality; they can also result in costly equipment damage.

3. CONNECTING NEGATIVE WIRES

Following the positive connections, the focus shifts to establishing the connections for the negative wires. Just like with the positive wires, ensuring that negative wires are of adequate length to reach the grounding point without excessive slack is essential. During installation, negative wires should be routed away from positive wires to avoid electromagnetic interference, which may compromise efficiency.

Once the length has been adjudged suitable, it’s time to connect the negative wires. The solar panel’s negative wire should be securely connected to either the grounding bar or the designated negative terminal of the charge controller. It is crucial to check for any corrosion before making connections because oxidized surfaces could hinder conductivity and increase resistance.

Furthermore, the integrity of these connections can’t be understated. Utilizing heat-shrink tubing or electrical insulation tape can provide additional protection against exposure to atmospheric elements. Tightly secured connections reduce the risk of unintended disconnections. Maintaining high-quality connections ensures a seamless flow of electricity back to the solar energy system, facilitating reliability throughout the entire operation.

4. SECURING CONNECTIONS

After successfully connecting all wires, the critical task of securing those connections becomes paramount. Using terminal blocks, wire nuts, or dedicated connectors can help ensure that connections remain secure even through variable environmental conditions.

Both electrical tape and heat-shrink tubing act as excellent protective layers for each terminal connection, preventing moisture ingress and avoiding short circuits. In grounding connections especially, it becomes necessary to implement corrosion-resistant materials that endure unforgiving weather conditions, which can lead to electrical failures if untreated.

Furthermore, implementing a routine maintenance schedule to inspect connections for wear, corrosion, or looseness can greatly enhance the lifespan of the solar energy system. Regular checks also enable early detection of potential issues before they develop into full-blown failures, ensuring your system operates efficiently. Comprehensive appreciation of secure wiring practices ultimately translates to reduced risks and maximized energy productivity.

5. TESTING CONNECTED SYSTEM

Once everything has been connected and secured, it’s time to perform testing. It’s advisable to use a multimeter to confirm that the connectivity aligns with expected voltage outputs. Observing voltage readings across the solar panel will reveal whether connections have been made correctly.

Testing becomes essential not just for immediate verification but also for long-term performance monitoring. Observed discrepancies can prompt immediate corrections, ensuring the long-term efficiency of the system. If problems arise, carefully retracing steps to examine each connection, along with ensuring that wires aren’t damaged or improperly oriented, becomes necessary for troubleshooting.

Using a multimeter not only for testing voltage but also for current draws can provide insights into the overall health of the connected system. If conditions allow, testing under different levels of sunlight can demonstrate how well the setup responds to fluctuations in solar radiation. Real-time performance can also help identify sections where adjustments or enhancements are necessary, keeping the solar energy generation process optimally tuned.

FAQS

WHAT TOOLS ARE NEEDED TO CONNECT SOLAR PANEL WIRES?

Connecting the two crucial wires of a solar panel necessitates several key tools for a safe and effective installation. Wire strippers, for instance, assist in removing insulation from wire ends while avoiding damage to the conductor itself. Furthermore, soldering iron or crimping tools can ensure that connections are made securely. Additionally, multimeters are indispensable for verifying voltage levels and checking for proper connections throughout the process.

Safety gear, such as gloves and goggles, is also advisable while handling wiring tasks, as they help mitigate risks associated with electrical shorts or encounters. For individuals looking to implement a grounding bar, employing screwdrivers or other fasteners may be required for installation too. Invoking these specific tools ensures an organized approach to wire connection, thereby enhancing performance continuity.

HOW TO TROUBLESHOOT SOLAR PANEL CONNECTION ISSUES?

When confronted with connectivity issues in a solar panel system, several steps should be meticulously followed. Start with ensuring that all terminals are securely fastened, eliminating the likelihood of physical disconnections as the first action. If voltage output readings fall short of expectations, utilizing a multimeter can help identify where the issue lies by checking each segment of wiring systematically.

Additionally, it’s essential to check for signs of corrosion or damage across all connection points. Corroded connections can significantly impact performance. If corrosion is observed, removing the affected wire and replacing it with a fresh conduit can reinstate functionality. Each aspect of the system should also be inspected critically for potential obstructions or shadows that might impair energy production.**

CAN SOLAR PANELS BE CONNECTED IN SERIES OR PARALLEL?

Indeed, solar panels can be interconnected in either series or parallel configurations, each serving different needs based on the desired voltage and current outputs. When panels are linked in series, the total voltage output is cumulative while the current remains constant. This setup can be advantageous in situations where higher voltage levels are required, most notably in cases of long-distance transmission or in conjunction with existing higher-voltage systems.

Conversely, parallel connections yield a collective current increase while maintaining equivalent voltage levels. This approach reduces risk by mitigating the impact of a single panel failure on the overall system. Each combination presents different characteristics, and careful consideration of system requirements should guide the decision.

FINAL THOUGHTS

Successfully connecting the four wires of a solar panel encompasses a series of essential tasks, each contributing to the overall efficiency and reliability of the solar power system. Understanding the specific functions of each wire forms the foundation for any effective wiring practice. The significance of securely connecting positive and negative terminals cannot be overstated, as weak links can diminish functionality and jeopardize investments. Tools for connecting, testing, and troubleshooting within solar installations must be readily available to ensure that any unforeseen issues can be promptly addressed.

Meanwhile, grounding practices and secure connections act as protective measures against the elements. Over time, regular inspections can reveal any wear or degradation that may require attention. System configurations such as series and parallel layouts further illustrate the flexibility and adaptability of solar technologies, enabling users to optimize per their unique energy needs. Proper connections, adept troubleshooting, and a commitment to preventive health checks are indispensable for maximizing returns on solar energy investments, paving the way for a sustainable energy future. Ultimately, equipping oneself with the right knowledge and tools allows individuals to navigate the complexities of solar installations, ensuring long-term operational efficiency, cost-effectiveness, and environmental benefits.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-4-wires-of-the-solar-panel/