Connecting solar tubes to PE pipes can be effectively accomplished through these steps: 1. **Utilizing appropriate fittings ensures a reliable connection between the two types of materials, 2. Employing sealants or thread tape is critical to prevent leaks, 3. Insulating joints helps to maintain efficiency, 4. Regular maintenance checks are vital to ensure longevity and performance. A detailed understanding of how to select and use proper fittings can be crucial to a successful integration. Fittings must have a compatible diameter and material to secure a tight connection, while also considering factors such as pressure ratings and environmental conditions. This process requires careful planning and execution to avoid future complications.

1. UNDERSTANDING SOLAR TUBES AND PE PIPES

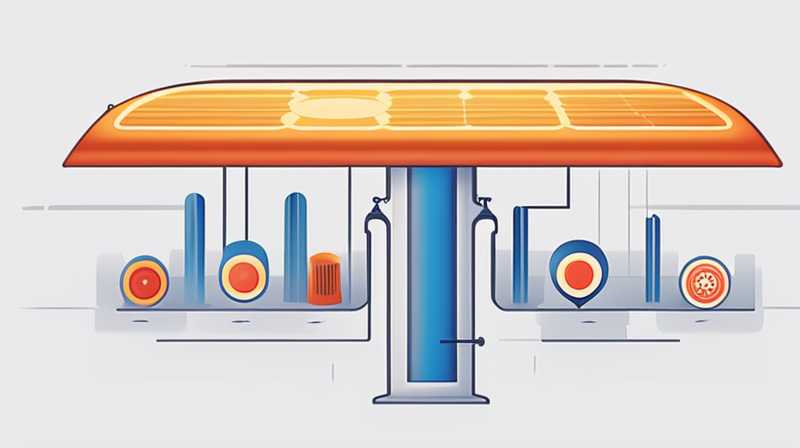

Integration of solar tubes with polyethylene (PE) piping systems constitutes a fundamental aspect of modern plumbing and renewable energy applications. Solar tubes, often referred to as evacuated tube collectors, play a quintessential role in harnessing solar energy for heating water. They operate through thermal conduction, efficiently converting sunlight into usable heat. On the other hand, PE pipes, characterized by their lightweight and corrosion-resistant nature, are utilized in various contexts, including irrigation and potable water supply. Understanding the functionalities of both systems is critical before embarking on the actual connection.

Combining these two technologies offers numerous benefits, including enhanced energy efficiency and a reduced carbon footprint. By effectively channeling solar energy through resilient piping systems, users can achieve significant cost savings over time. The desirability of establishing a robust connection between solar tubes and PE pipes lies not only in their operational advantages but also in the seamless integration that reduces energy loss and boosts performance. Hence, a thorough examination of the components and tools necessary for this undertaking is imperative.

2. CHOOSING THE RIGHT FITTINGS

When engaging in the connection of solar tubes with PE pipes, selecting the appropriate fittings is essential for success. Fittings serve as the intermediary components that facilitate the union of different pipe materials and diameters. Various fittings, such as couplings, elbows, and tees, must be compatible with both the solar tube outlet and the PE pipe inlet. It is of utmost importance to consider parameters such as pressure ratings and temperature thresholds, ensuring that the chosen fittings can withstand the operational conditions posed by both solar energy systems and PE piping.

The installation process must be methodical, highlighting the importance of precision. Although there are pre-assembled fittings available, custom-fitting options may be applicable depending on your unique project specifications. Proper tooling is critical; users must employ correct tools to avoid damage to the fittings and ensure that connections are tight. Over time, improper fittings can lead to leaks, a phenomenon that can compromise the efficiency of the entire system. Thus, extensive research and careful selection based on technical specifications prove beneficial in the long run.

3. SEALANTS AND THREAD TAPE USAGE

Once fittings are chosen, the next step reaches the application of sealants and thread tape. Utilizing these materials becomes pivotal in achieving a watertight seal at connector joints. Thread tape, categorized as Teflon tape, is particularly advantageous as it fills spaces between threads, minimizing the chances of leaks occurring. When wrapping thread tape around threaded connections, it’s crucial to apply it in a clockwise manner, ensuring that the tape doesn’t unravel when screwing the fittings together.

Sealants, on the other hand, come in various formulations, including silicone-based or rubber-based options tailored for plumbing applications. The application process dictates a thin and even layer of sealant on threads and joint surfaces, helping to achieve a secure fit between the solar tube fittings and PE pipes. The drying time of sealants must be taken into account; thus, users should allow adequate time for curing before running any liquids through the newly engaged system. Ensuring these steps are observed averts problems that could manifest in the future.

4. INSULATION FOR ENERGY EFFICIENCY

Insulating the connection points of solar tubes and PE pipes plays a critical role in conserving energy and enhancing system efficiency. Heat loss through joints can undermine the overall effectiveness of the solar energy systems, rendering efforts futile. It is vital to select an insulation material that can withstand environmental demands while successfully minimizing heat transfer. Common insulation materials include fiberglass, foam insulation, and specialized jackets that provide thermal resistance.

Proper installation of insulation involves wrapping it securely around the points of connection and ensuring that it covers all exposed areas. Special attention should also be given to areas that may experience outdoor exposure, as environmental factors can easily compromise unprotected joints. Insulation should be evaluated regularly to assess its condition and effectiveness—signs of wear or damage necessitate immediate replacement or repair to maintain optimal performance levels.

5. MAINTENANCE CHECKS FOR LONGEVITY

Periodic maintenance checks of both the solar tubes and PE pipes are indispensable for sustaining functionality and longevity. Establishing a routine inspection schedule can unveil potential issues before they escalate into significant failures. Look for signs of wear, such as cracks or leaks in the piping, signs of corrosion in fittings, or a substantial decrease in performance from the solar system. Catching problems early enables prompt action, be it through minor repairs or the complete replacement of components.

Additionally, keeping the components clean ensures they operate effectively. For solar tubes, this includes checking for obstructions that may hinder sunlight absorption; for PE pipes, regular flushing can prevent buildup that limits water flow. Engaging in regular assessments not only extends the life cycle of the installation but also maximizes return on investment—reducing long-term costs associated with inefficient operations or major repairs.

6. CONNECTING SOLAR TUBES TO PE PIPES: STEP-BY-STEP APPROACH

The amalgamation process of solar tubes with PE pipes is both intricate and systematic. To embark on this venture successfully, a comprehensive strategy is paramount. Initiate the connection by preparing suitable workspace conditions. Ensure that the area is clean and free of moisture or contaminants that could disrupt the joining process. Gather all required materials, including solar tubes, PE pipes, appropriate fittings, sealants, thread tape, insulation materials, and maintenance tools.

Following the preparation phase, the actual connection process commences. Carefully align the solar tube outlet with the selected fitting, ensuring that it is tightly secured but not overtightened, as excessive force can lead to cracks. Apply thread tape to threaded connections and sealants where necessary, establishing a seal between the interfaces. Once all fittings are in place, complete the assembly by insulating exposed connection points. This safeguards against potential heat loss while also providing additional durability against environmental impacts.

After successfully connecting the components, the system should undergo a trial run. Inspect for leaks by applying pressure to the system and monitoring the connection points closely. Should any leaks arise, dismantling may be necessary; this emphasizes the importance of starting with meticulous precision during the installation stages. Once satisfied that no leaks are present, applause this achievement with regular maintenance checks to ensure that the system operates efficiently over time.

7. BENEFITS OF CONNECTING SOLAR TUBES TO PE PIPES

Embracing the connection of solar tubes to PE pipes brings forth a multitude of advantages that extend beyond immediate energy savings. A primary benefit includes the reduction in logistical challenges when transporting heated water for residential or commercial applications. With an efficient design, users can experience reduced operational costs and a minimized environmental footprint. The compatibility of these two materials ensures that the installed system remains durable under various operational conditions, highlighting their collective advantages.

Furthermore, the longevity of both solar tubes and PE pipes contributes to a sustainable energy framework. As long-lasting options, they negate the necessity for frequent replacements, translating to lowered waste production. Moreover, various government incentives for utilizing renewable energy technology can further enhance the economic returns experienced by adopting this innovative connection. In essence, the combination of solar tubes and PE pipes represents a step forward in eco-friendly energy solutions, aligning with broader sustainability goals while servicing essential needs.

FREQUENTLY ASKED QUESTIONS

HOW DOES ONE DETERMINE THE IDEAL SIZE FOR FITTINGS BETWEEN SOLAR TUBES AND PE PIPES?

To ascertain the suitable size for fittings bridging solar tubes and PE pipes, an individual must evaluate the specified dimensions of both systems. It is paramount to adhere to the manufacturer guidelines concerning pipe diameters and corresponding fitting sizes to establish a fitting that can handle thermal expansion and pressure fluctuations. Furthermore, ensuring compatibility prevents the risk of leaks that could arise from improper dimensions. Utilizing tools like calipers or pipe measuring gauges allows for precise measurements, facilitating better integration. Engineers should always consider potential future expansions or modifications, which may necessitate adjusting sizes accordingly to accommodate evolving needs.

WHAT COMMON MISTAKES SHOULD BE AVOIDED DURING THE CONNECTION PROCESS?

Several pitfalls may hinder a successful connection between solar tubes and PE pipes. A prevalent mistake involves inadequately preparing surfaces before applying pressure; dirt or moisture can compromise fittings and sealants. Another common issue stems from neglecting manufacturer specifications, leading to potential compatibility problems. Additionally, using inappropriate tools can result in damage to the components or unsafe connections. Furthermore, overlooking insulation or prematurely testing the system before ensuring proper curing of sealants can lead to inefficiencies or failures. Careful adherence to each step and reference to the product guidelines will work in favor of achieving a reliable and enduring connection.

WHAT IS THE SUSTAINABILITY SIGNIFICANCE OF CONNECTING SOLAR TUBES TO PE PIPES?

The sustainability significance of linking solar tubes to PE pipes lies in their coalescing functionalities within the realm of renewable energy solutions. Solar tubes maximize solar energy potential while PE pipes transport that resource efficiently, fostering an avenue that reduces reliance on hazardous materials and fossil fuels. On a grander scale, utilizing these technologies can contribute markedly to lowering greenhouse gas emissions, given that they create a cycle of clean energy generation and delivery rather than dependence on traditional, polluted methods. This alignment with global sustainability goals offers individuals and businesses a method to address climate issues while simultaneously reaping the economic benefits of renewable sources.

FULFILLING CONNECTIONS WITH SOLAR TECHNOLOGY AND PE PIPING SYSTEMS REQUIRES CREATIVITY AND PRECISION.

By meticulously navigating procedures, one can foster optimal performance and efficiency for their operations. Each aspect of this connection—be it the careful selection of fittings, prudent application of sealants, thermal insulation strategies, or regular maintenance checks—contributes to a well-functioning system. Understanding the multifaceted components at play equips operators with the knowledge to achieve a sustainable energy infrastructure, reducing their environmental impact while improving the longevity and efficacy of their systems. Additionally, the collective knowledge gained through the connection process enhances the understanding of renewable technology, leading the way to innovative energy solutions for the future.

ESTABLISHING CONNECTIONS IN RENEWABLE TECHNOLOGY PRESENTS OPPORTUNITIES FOR PERSONAL AND ENVIRONMENTAL BENEFITS ALIKE.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-solar-tubes-to-pe-pipes/